Vineethkumar01

Well-Known Member

Hello All,

I am starting a 2 way horn project (configuration remains 2 way for now. May become 3 way if we hit design limitations later). The drivers (for now) will be a 15inch Faital pro 15PR400-8 (https://faitalpro.com/en/products/LF_Loudspeakers/product_details/index.php?id=101060100) as the mid-woofer and a compression driver in a horn for the upper end (Let's consider that the CD is SB Audience Rosoos-65 CDN-T 1.4inch neodymium compression driver (http://www.sbaudience.com/index.php/products/compression-drivers/rosso-65cdn-t/) ). The horn/waveguide which will load this driver is yet undecided (there are always options like LTH series horns from faital and other options from 18 sound etc but I want to build a customized horn). I am in the process of asking friends regarding feasibility of getting a horn made. The crossover will be active with DSP.

). The horn/waveguide which will load this driver is yet undecided (there are always options like LTH series horns from faital and other options from 18 sound etc but I want to build a customized horn). I am in the process of asking friends regarding feasibility of getting a horn made. The crossover will be active with DSP.

My projects often stall at the phase where we have to put drivers in a proper cabinet. This is due to me having no time and space to do woodworking where I live. I am also not able to get help from friends/others (at this time since everyone is busy with office work after return to office kind of policies) who know woodworking in getting this part done .. Hopefully, I will get cabinets made with someone's help later but till then we explore and learn. With this limitation aside, let us try to make the learning process involved in the design of such a speaker as much fun and useful (to all of us) as possible..

Hopefully, I will get cabinets made with someone's help later but till then we explore and learn. With this limitation aside, let us try to make the learning process involved in the design of such a speaker as much fun and useful (to all of us) as possible..  This is the motivation behind this thread.

This is the motivation behind this thread.

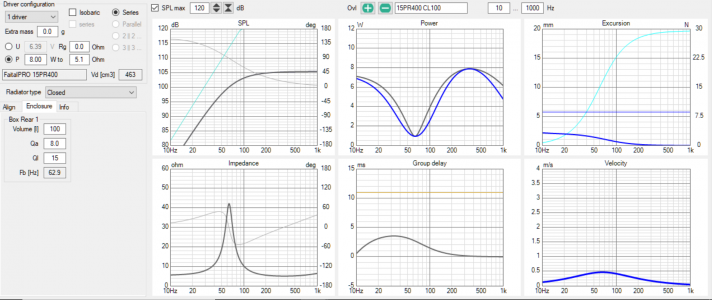

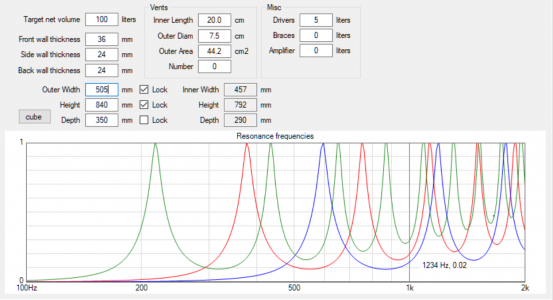

I will start with trying to come up with a box (bass) alignment for the woofer. My listening space is either a 16ish m2 room or a 25ish m2 room. My constraints for the cabinet are 1) It should be manageable size 2) It should look good. Without these two, I along with my projects will be kicked out of the house

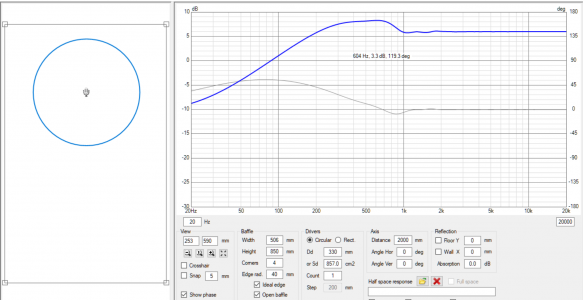

With these thoughts in mind, I have chosen a cabinet shape as shown in attached pics-1 and 2 (shows back and front of intended cabinet shape). A possible shape with woofer and horn is shown in pic 3 (with/without ports). It favors corner placement in addition to moving away from the rectangular box design, which may come with its own advantages in terms of standing wave mode suppression etc (will verify all these later with measurements).

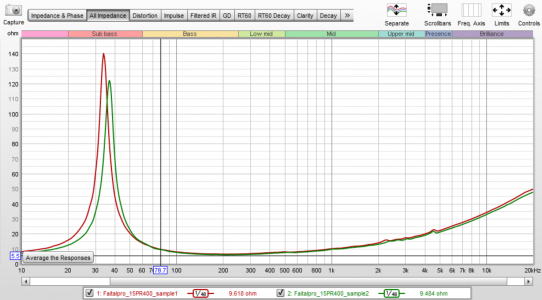

For now, please see the measured impedance curves for the two woofers that I have in the attached pic 4 (without any 'break in')

I will update this space with T/S parameter measurements of the drivers, further measurements baffle/cabinet sizes, etc next.

Welcoming your comments and suggestions

I am starting a 2 way horn project (configuration remains 2 way for now. May become 3 way if we hit design limitations later). The drivers (for now) will be a 15inch Faital pro 15PR400-8 (https://faitalpro.com/en/products/LF_Loudspeakers/product_details/index.php?id=101060100) as the mid-woofer and a compression driver in a horn for the upper end (Let's consider that the CD is SB Audience Rosoos-65 CDN-T 1.4inch neodymium compression driver (http://www.sbaudience.com/index.php/products/compression-drivers/rosso-65cdn-t/)

My projects often stall at the phase where we have to put drivers in a proper cabinet. This is due to me having no time and space to do woodworking where I live. I am also not able to get help from friends/others (at this time since everyone is busy with office work after return to office kind of policies) who know woodworking in getting this part done ..

I will start with trying to come up with a box (bass) alignment for the woofer. My listening space is either a 16ish m2 room or a 25ish m2 room. My constraints for the cabinet are 1) It should be manageable size 2) It should look good. Without these two, I along with my projects will be kicked out of the house

With these thoughts in mind, I have chosen a cabinet shape as shown in attached pics-1 and 2 (shows back and front of intended cabinet shape). A possible shape with woofer and horn is shown in pic 3 (with/without ports). It favors corner placement in addition to moving away from the rectangular box design, which may come with its own advantages in terms of standing wave mode suppression etc (will verify all these later with measurements).

For now, please see the measured impedance curves for the two woofers that I have in the attached pic 4 (without any 'break in')

I will update this space with T/S parameter measurements of the drivers, further measurements baffle/cabinet sizes, etc next.

Welcoming your comments and suggestions