turgid

New Member

Hello,

I should have posted this on the 17th of May, back when I finished working on my ESL and played it for all of 2 minutes before it snapped and started leaking charge.

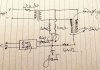

If I delay things any further, memory will start polluting those 2 minutes with superlative words, so posting the schematics and also some pictures. It took about 1 min. for the diaphragm to charge up, I expected more time for that.

As for the sound - I was pretty convinced that the very small dimensions of the active area - 12cm by 23 cm would cause a considerable frequency roll-off anywhere by 700-1KHz but this was not the case. What stood out to me were the clarity, distinction and sonic spacing of the instruments that made it sound very very open. It sounded huge considering the size of the speaker. I thought there would be a drastic roll-off as already mentioned but the ESL suffered serious lowered decibel levels at texturing the bass guitars but each note stood out clean and clear from the rest. I couldn't hear any bass drum except for a low pop sound(probably due to the diaphragm hitting the stators).

The reason the bass was more is probably due to the slightly thicker diaphragm material that I used(more on that later).

Vocals were the strong suit and the details were crisp. The treble sounded awfully bright and harsh at first but settled down for a clean sound. There was also a noise floor and the space between notes was covered with this noise.

Will post more impressions upon request albeit from memory. I wish I had made a video of it before it snapped. I will put up some more pics tomorrow.

Cheers,

Azaan

I should have posted this on the 17th of May, back when I finished working on my ESL and played it for all of 2 minutes before it snapped and started leaking charge.

If I delay things any further, memory will start polluting those 2 minutes with superlative words, so posting the schematics and also some pictures. It took about 1 min. for the diaphragm to charge up, I expected more time for that.

As for the sound - I was pretty convinced that the very small dimensions of the active area - 12cm by 23 cm would cause a considerable frequency roll-off anywhere by 700-1KHz but this was not the case. What stood out to me were the clarity, distinction and sonic spacing of the instruments that made it sound very very open. It sounded huge considering the size of the speaker. I thought there would be a drastic roll-off as already mentioned but the ESL suffered serious lowered decibel levels at texturing the bass guitars but each note stood out clean and clear from the rest. I couldn't hear any bass drum except for a low pop sound(probably due to the diaphragm hitting the stators).

The reason the bass was more is probably due to the slightly thicker diaphragm material that I used(more on that later).

Vocals were the strong suit and the details were crisp. The treble sounded awfully bright and harsh at first but settled down for a clean sound. There was also a noise floor and the space between notes was covered with this noise.

Will post more impressions upon request albeit from memory. I wish I had made a video of it before it snapped. I will put up some more pics tomorrow.

Cheers,

Azaan

Attachments

-

10246401_627983720609920_6113671669294374310_n.jpg24.8 KB · Views: 310

10246401_627983720609920_6113671669294374310_n.jpg24.8 KB · Views: 310 -

1797575_639467586128200_7787186298249792187_n.jpg19.5 KB · Views: 302

1797575_639467586128200_7787186298249792187_n.jpg19.5 KB · Views: 302 -

10402889_639467679461524_4773600685193154744_n.jpg20.1 KB · Views: 302

10402889_639467679461524_4773600685193154744_n.jpg20.1 KB · Views: 302 -

10366139_639467722794853_333406112757937349_n.jpg7.4 KB · Views: 303

10366139_639467722794853_333406112757937349_n.jpg7.4 KB · Views: 303 -

10403463_639467812794844_8487048610103662189_n.jpg10.7 KB · Views: 303

10403463_639467812794844_8487048610103662189_n.jpg10.7 KB · Views: 303