contd....

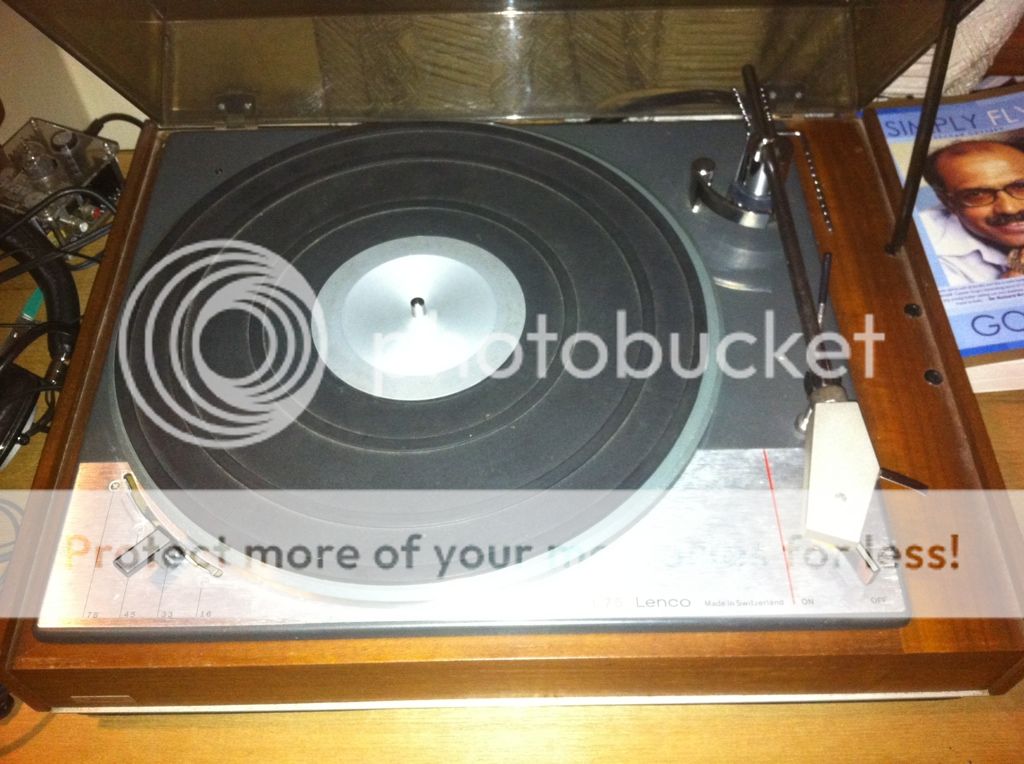

So, now that I had the Lenco, I discussed with knowledgable members here and also my reading on Lencoheaven suggested that the stock box plinth and the tonearm were the Lenco's weakest links. So I planned to fix these issues, tweak things a bit and make this my primary source for my Altec A7s.

This will be a total DIY effort (including woodwork) and here are some of the thing I want to do:

Make a multi-layered plinth using CLD (Constrained Layer Damping) approach

Have 2 tonearms - a 9 incher with a MM cart and a 12 incher with a MC cart - like a Ortofon SPU or a Denon DL-103

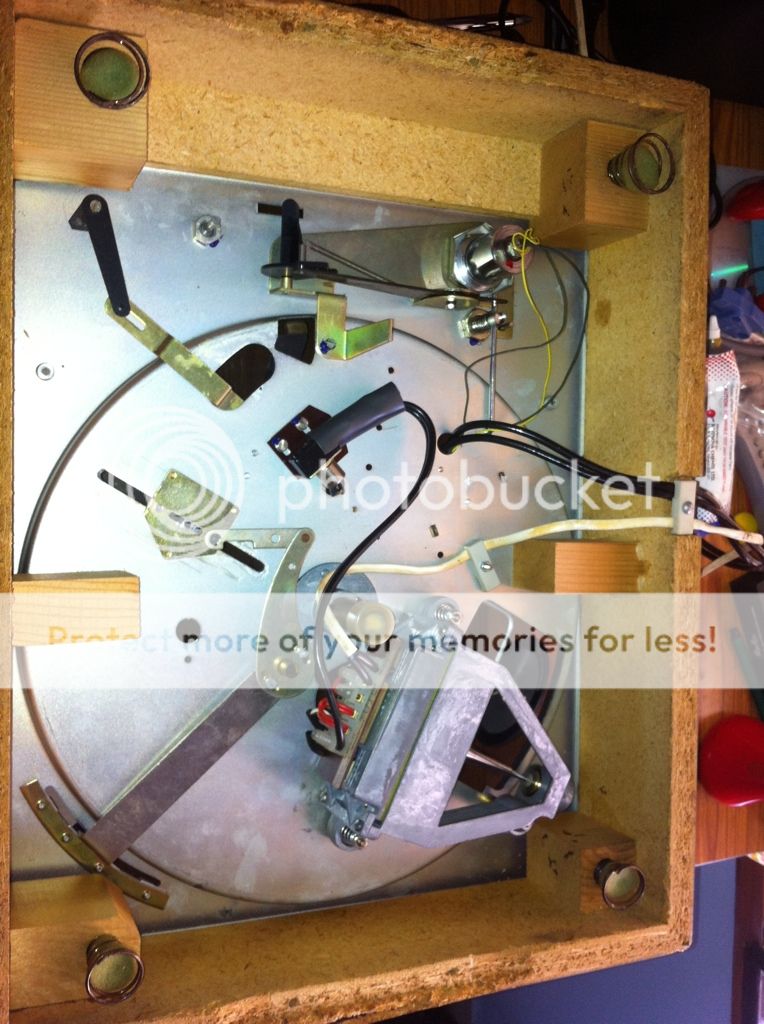

Service the motor and lubricate all the parts

Improve/change wiring and also add

earthing to the top plate

I like to build/re-build things in a phased manner as it is easier on my pocket & time and also I can listen and learn at every step.

Like I mentioned above, I wanted two tonearms and I wanted the 9 incher to go into the standard location while the 12 incher would be isolated from the plinth. The rationale behind two arms is to have the ability to have two different presentations - vintage sound as well as hi-fi/high res sound depending on the genre.

So for the vintage sound, I bought a 9 inch Jelco ST-250. Apart from being a well made arm, it also fulfilled another criteria which was that should fit into the Lenco's stock tonearm slot. This arm has the same geometry as the Lenco's stock arm (also shares geometry with Linn and Project arms). Here is a link with some specs and also says nice things about the arm

Jelco Tonearm

Jelco Tonearm

So, the arm arrived yesterday from US eBay -> Borderlinx.

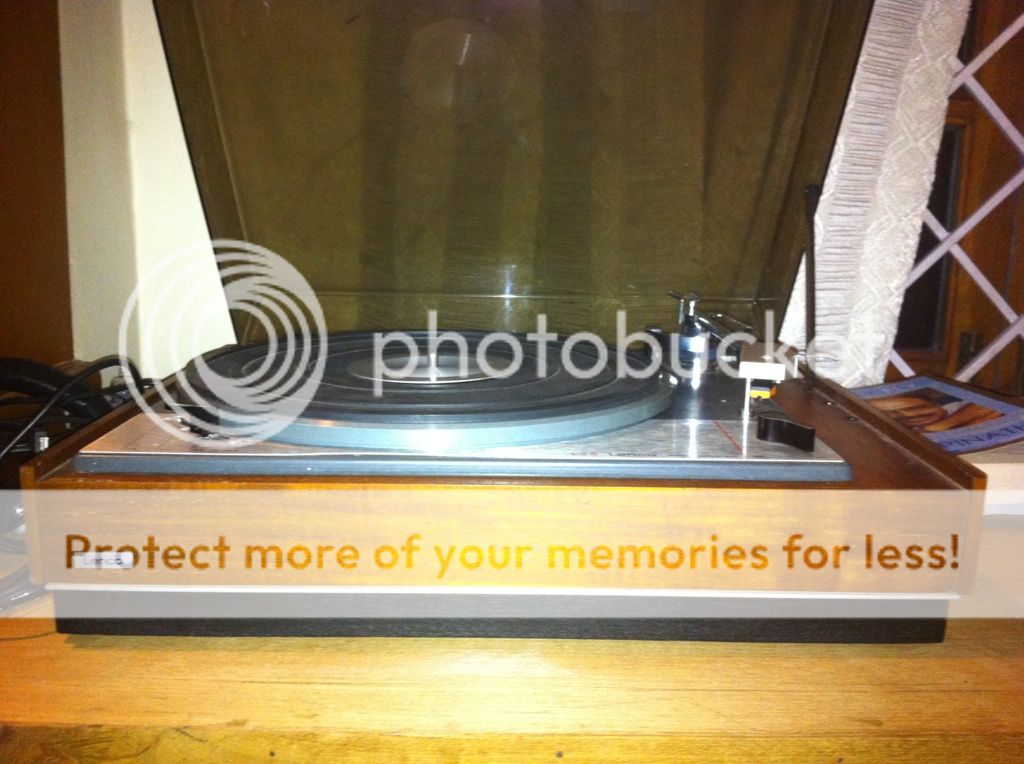

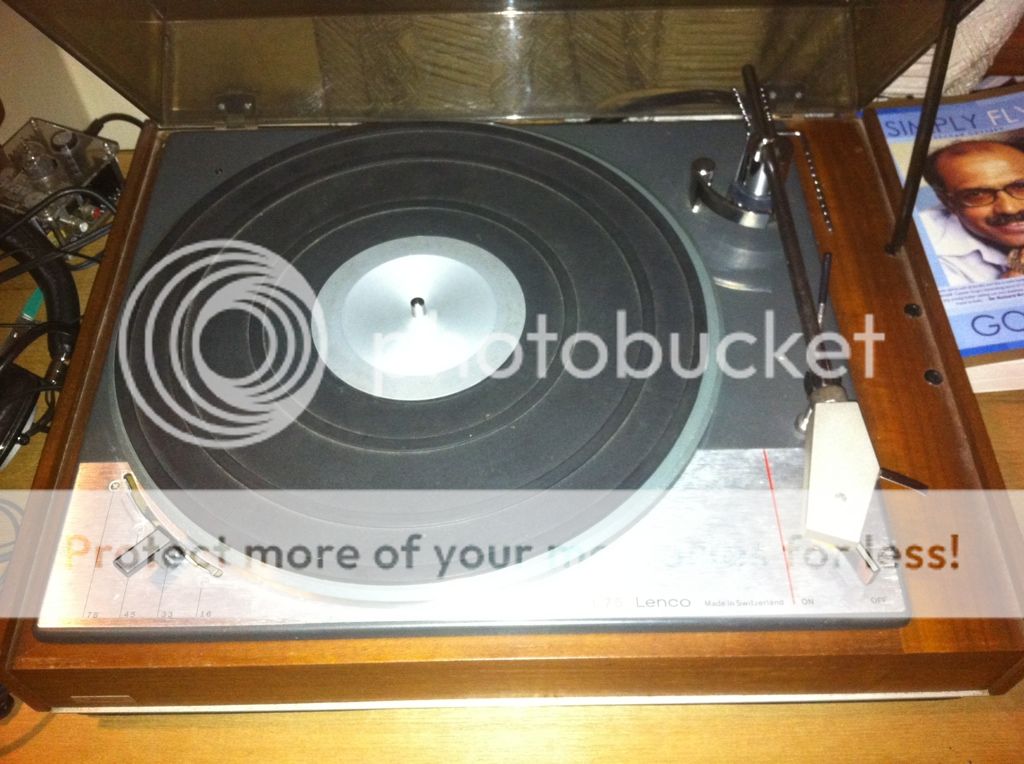

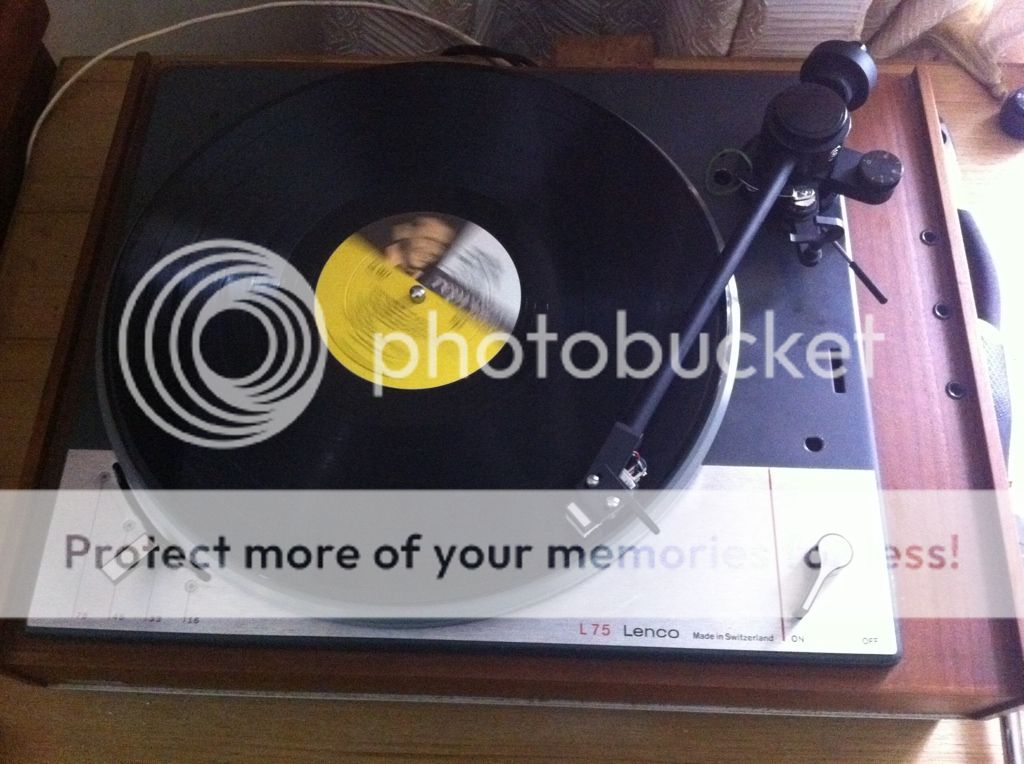

Lenco L75 Build :: 6830550C-A0D8-4C32-9979-45A4F00EEE79-1798-000003E900E77D9E picture by diyable - Photobucket

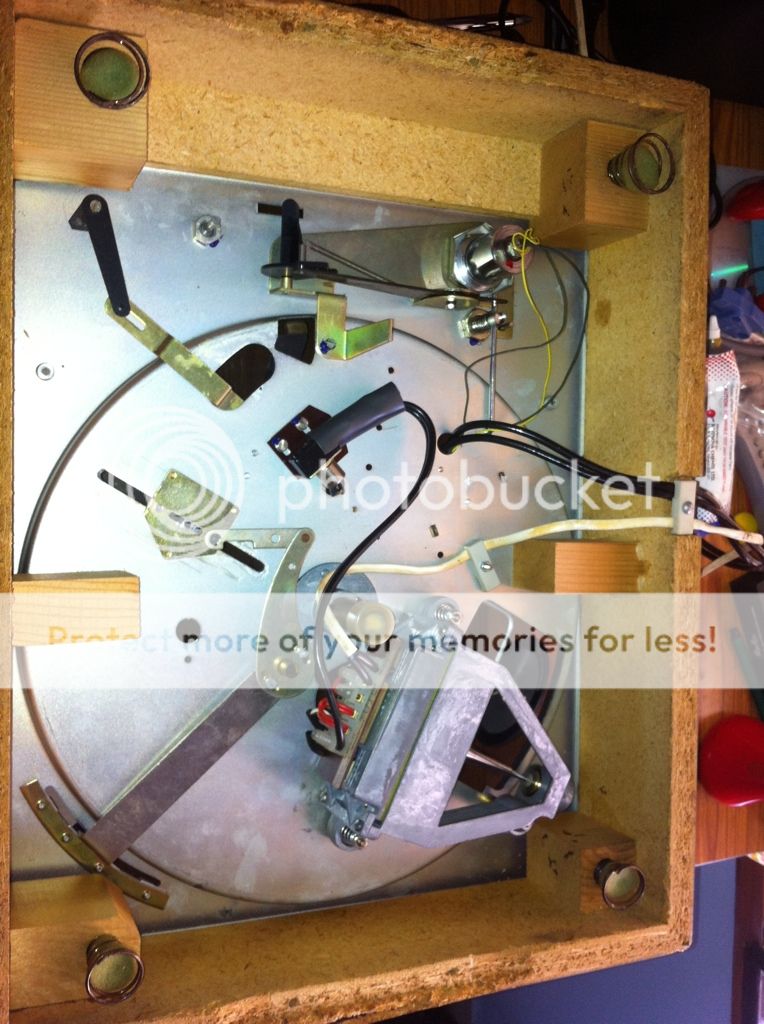

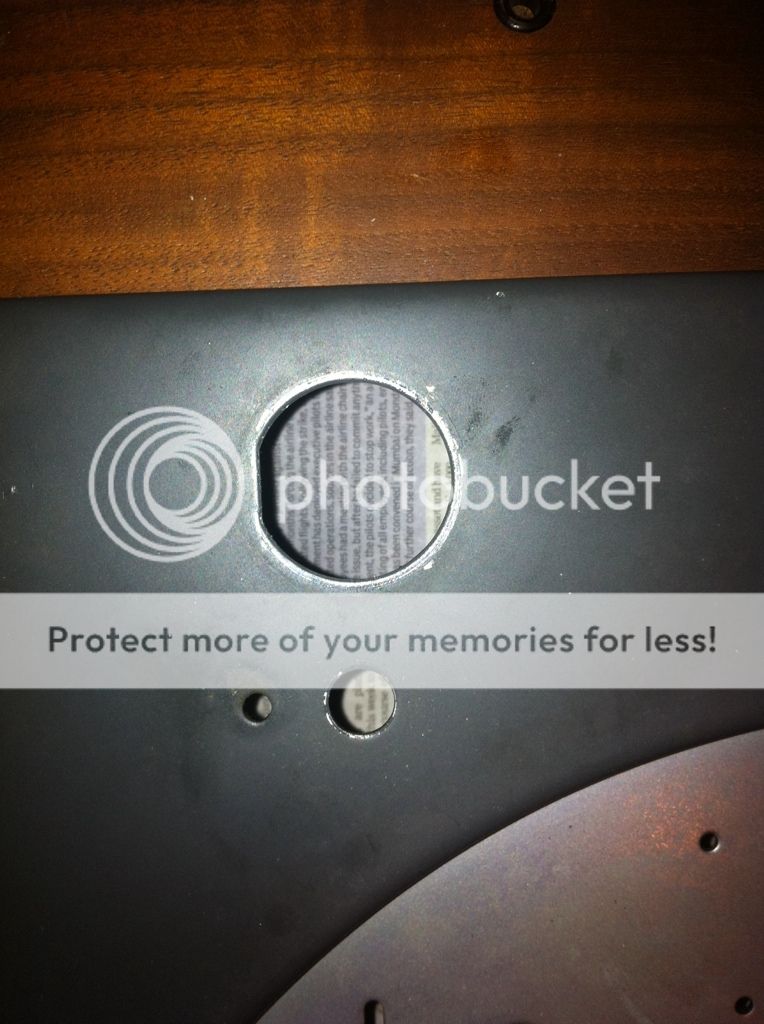

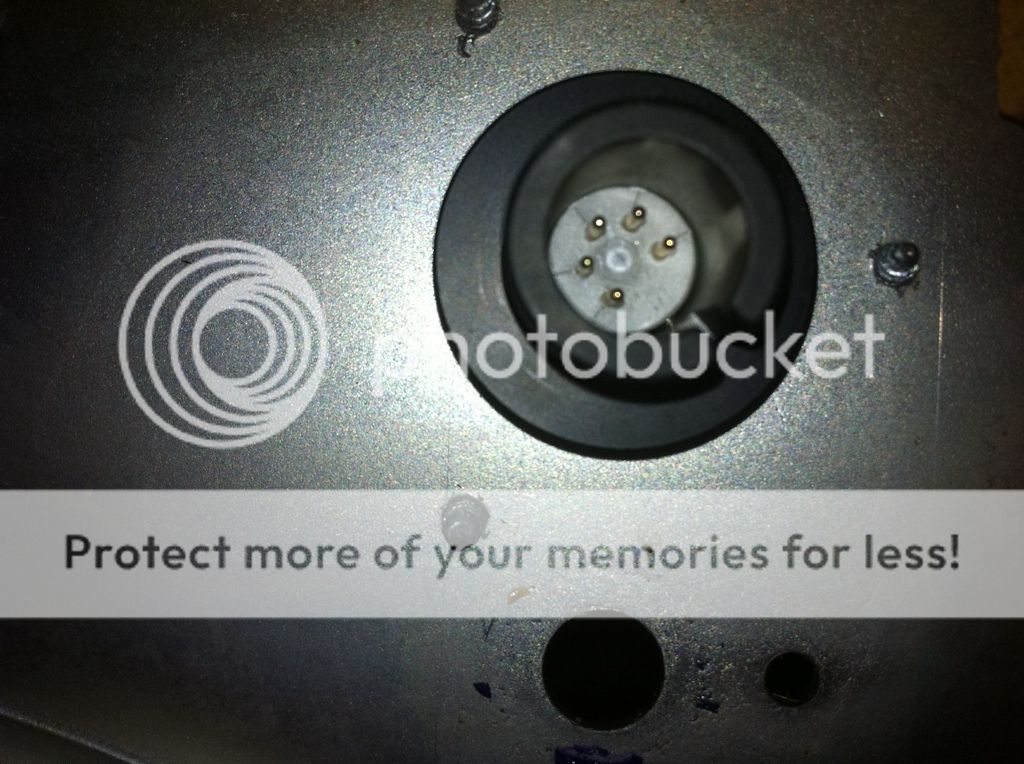

I dismantled and removed the stock tonearm and all the related mechanism like lift/drop mechanism etc and tried to drop in the Jelco tonearm but it wouldn't because though the hole is of the correct size, it was in the shape of a slight 'D' while the tonearm shaft was circular:sad:

Nothing that a simple file cannot fix. So, fixed the transport screws so the motor or anything else was not affected by the vibrations from filing and the subsequent drilling that was to follow. Since I had removed the platter, I covered it with a cloth so fine metal shavings, burr etc would not get into the mechanicals as IMO this can cause seizure. I made sure that I only filed as much was required, so the D shape is still maintained if there is a need for stock tonearm to be fitted again.

Then I drilled 3 holes so the tonearm base can be fitted:

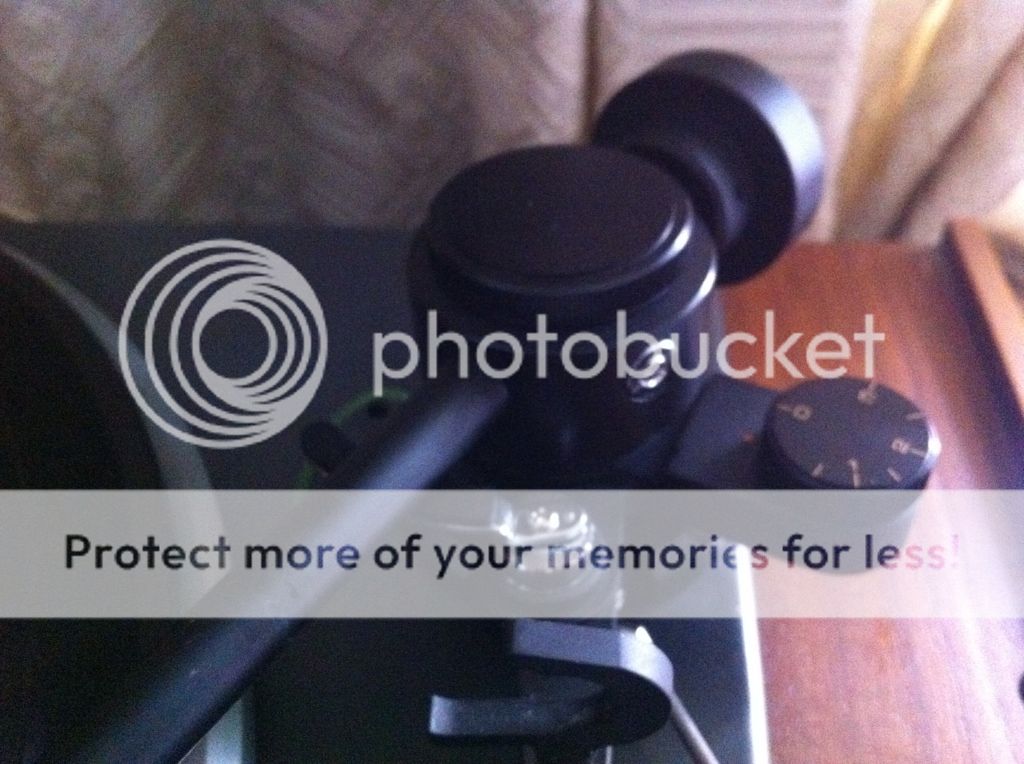

Tonearm base was then fitted:

The Jelco headshell does not have leads for the cartridge, since I did not have any other, I used the cartridge leads from my Pioneer TT. I also plan to use the stock Pioneer PC-11 MM cart temporarily(?) as it is a very musical cart and also also JICO makes a SAS stylus for this cart.

Pioneer PC-11

It came with a shim. I decided to use it since the Jelco can handle the extra 1.5 grams that the shim weighed. I will experiment with and without it and leave it if it sounds better with it

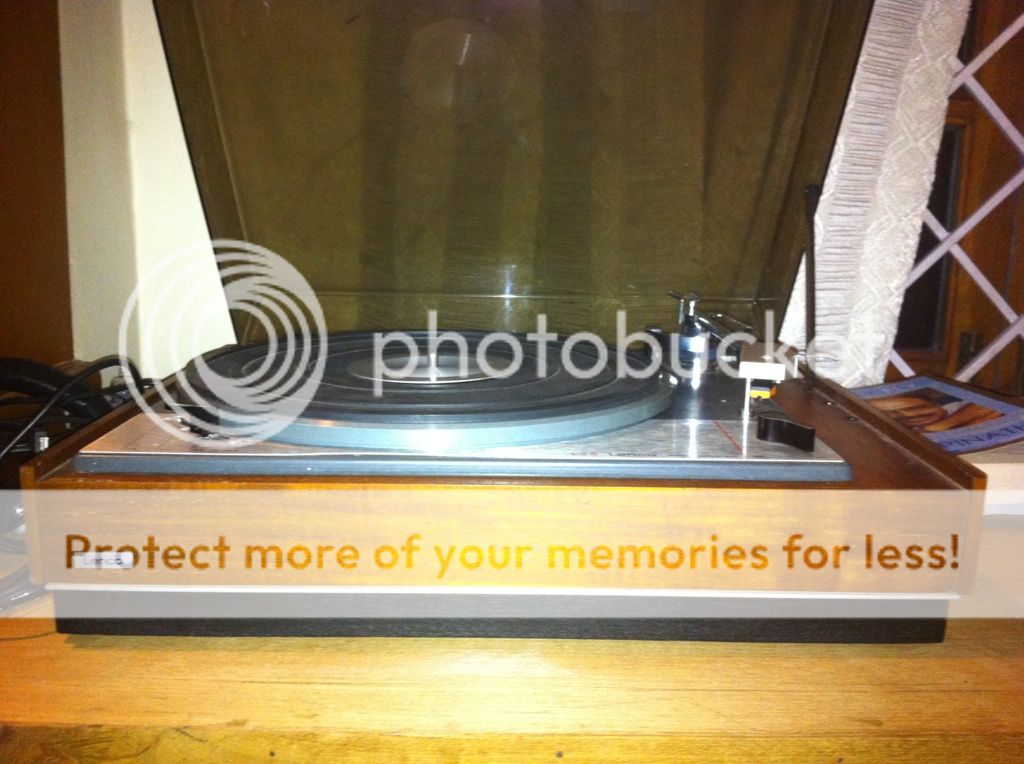

Some pics of the deck after mounting the tonearm, fixing and aligning the cart: