Soldering is fun!  :lol:

:lol: hyeah:

hyeah:

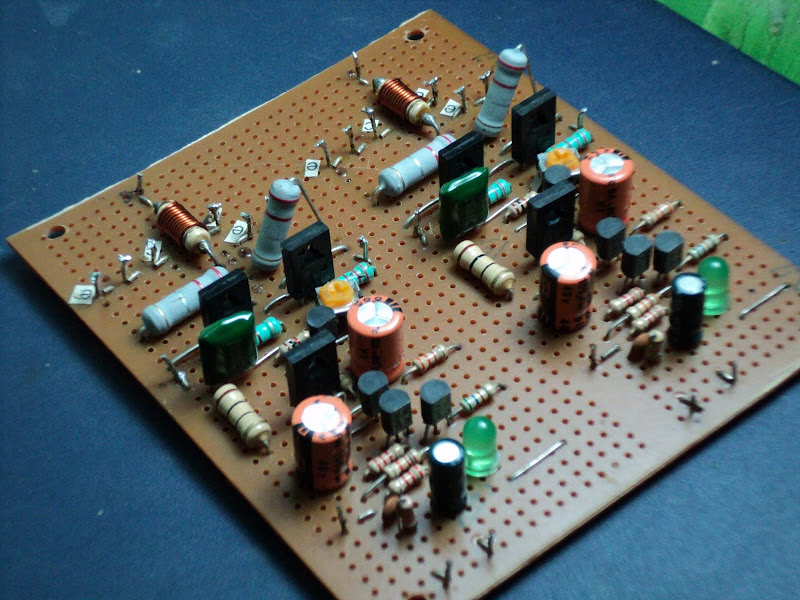

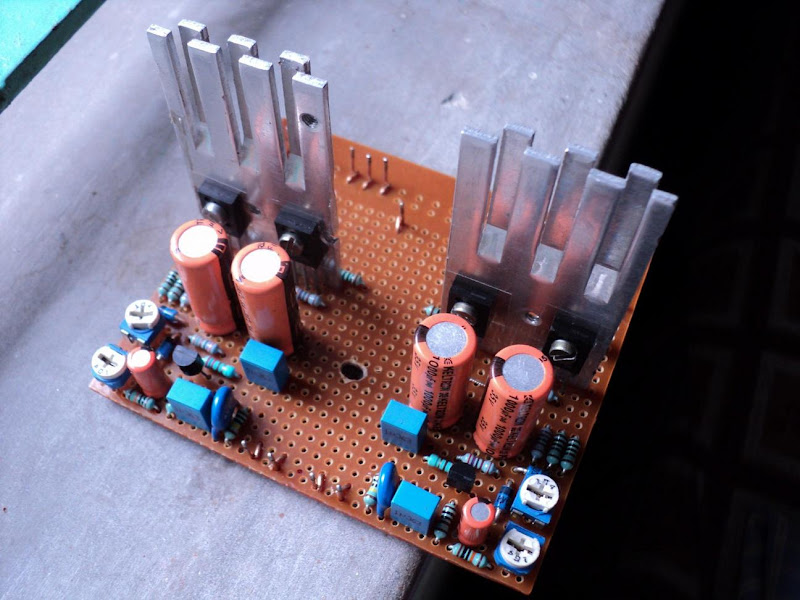

Old Class-AB quassi-complementary for 2N3055

Pavel Macura's MOSFET Power Follower SE Class-A Source Follower

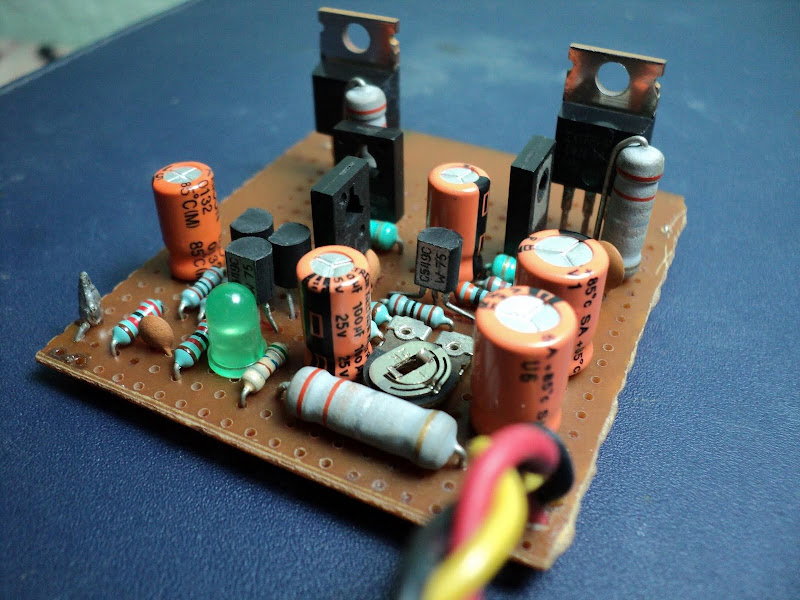

IRF540 Class-AB Little Monster(Excellent Bass)

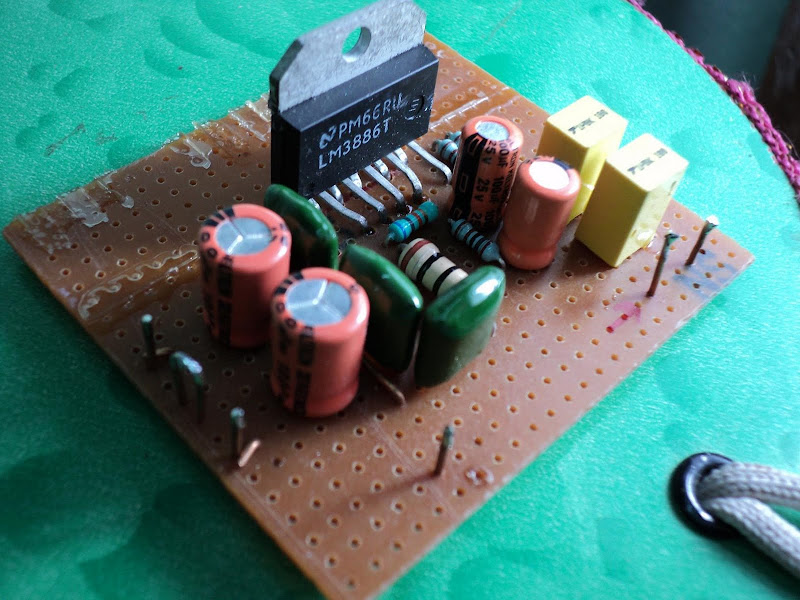

LM3886 Chipamp

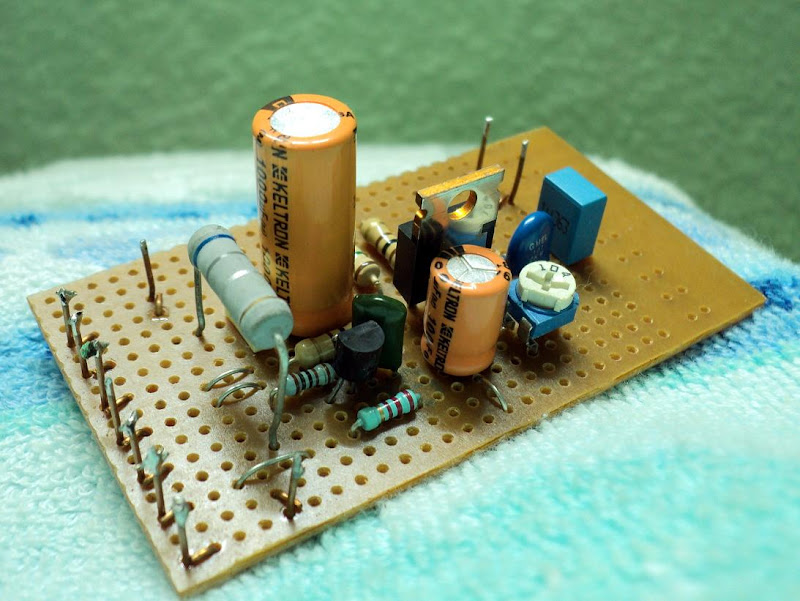

Guitar Preamplifier with Diode Clipping distortion

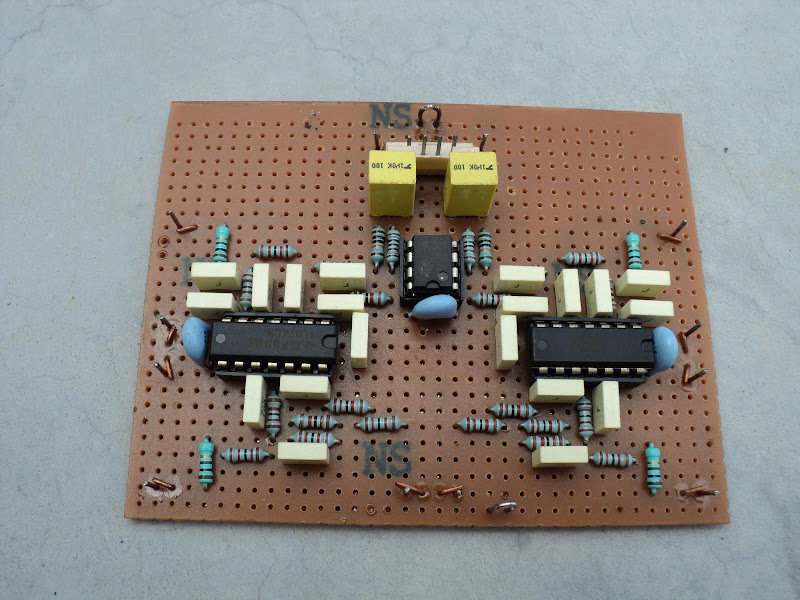

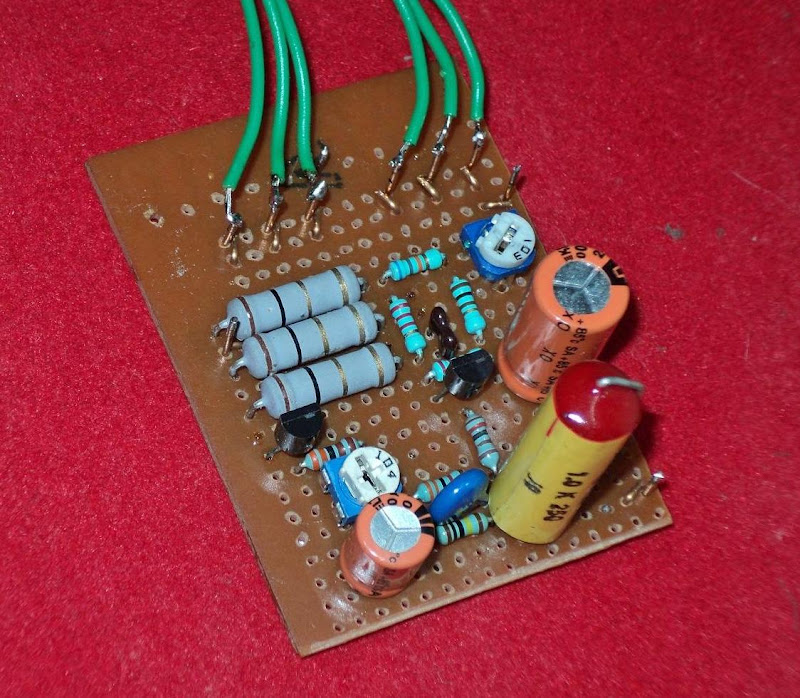

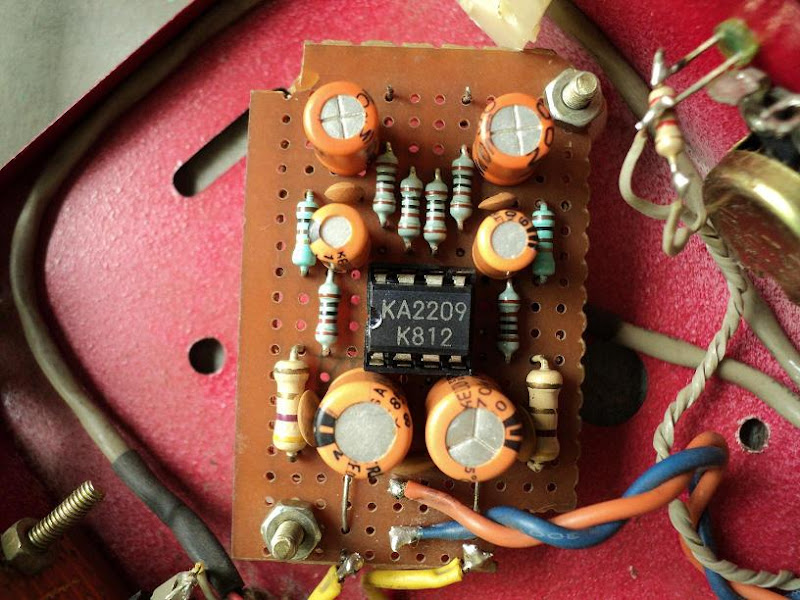

Linkwitz-Riley 24dB/octave active crossover

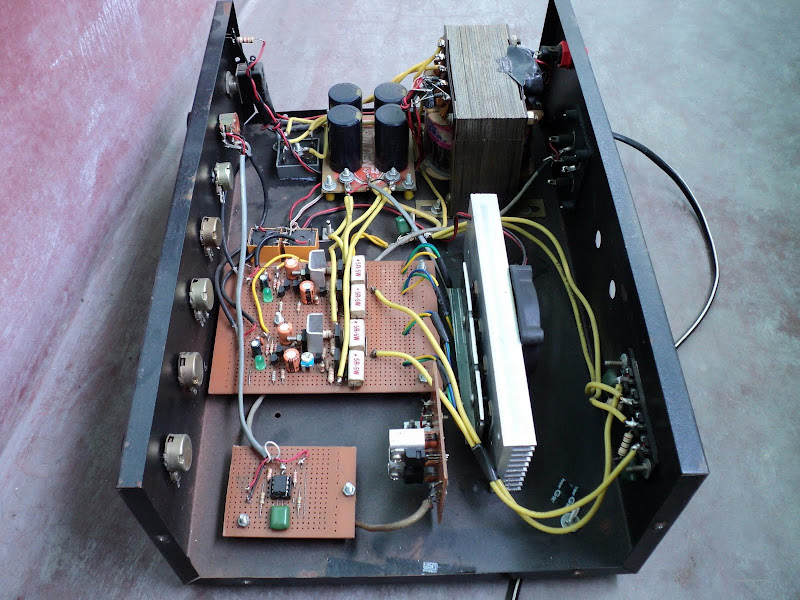

Finished old (and sold) Class-AB amp

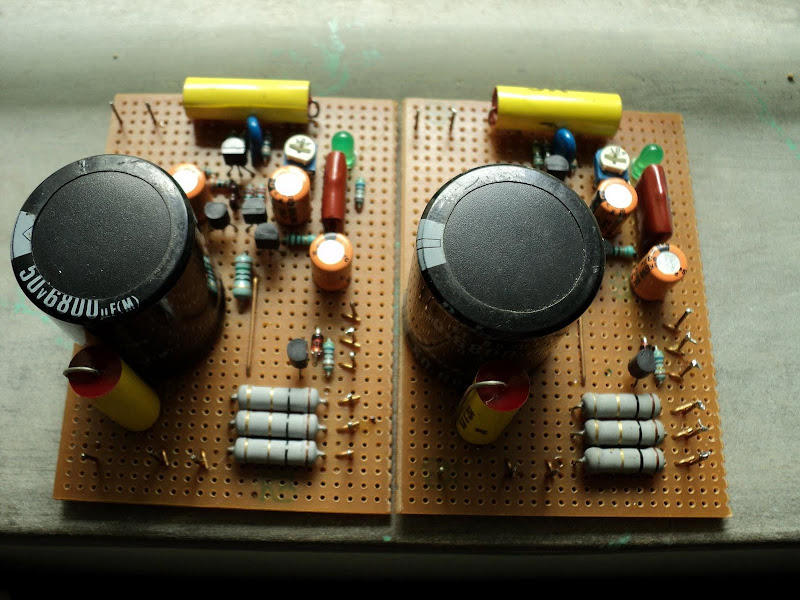

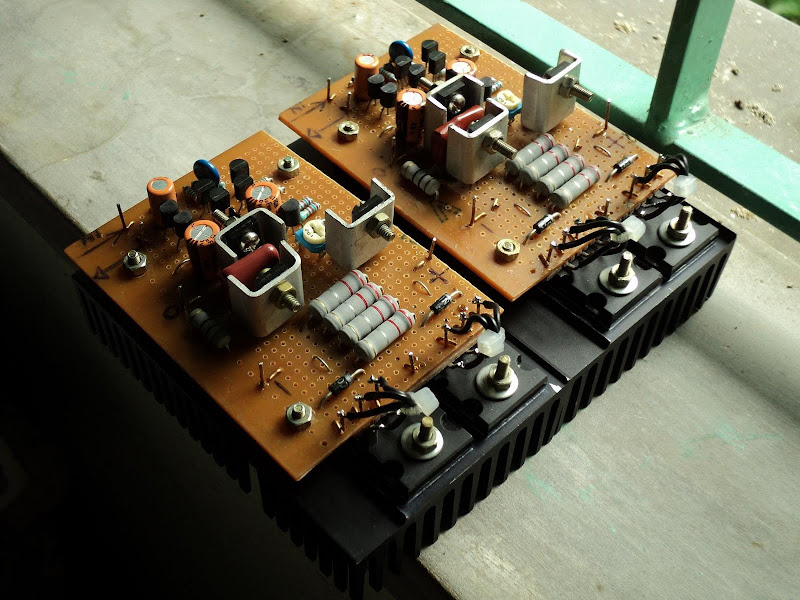

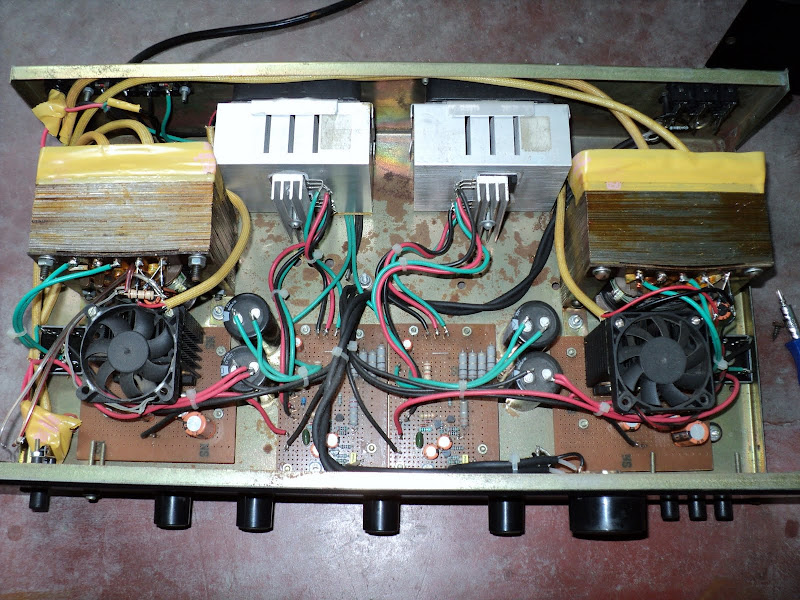

2SC5200 quassi-complementary Subwoofer Plate amps

Planning...

ESP P101 Clone(with guessed parts )

)

HEXFET input experimental SE Class-A amp(2 gain stage)

ESP Subwoofer Processor (Small but Magical hyeah: )

hyeah: )

ESP Thermo-Fan controller

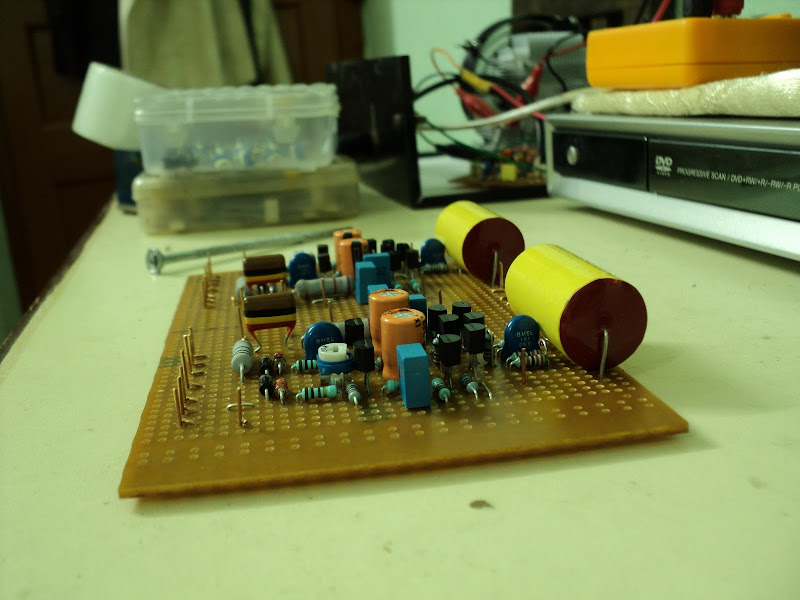

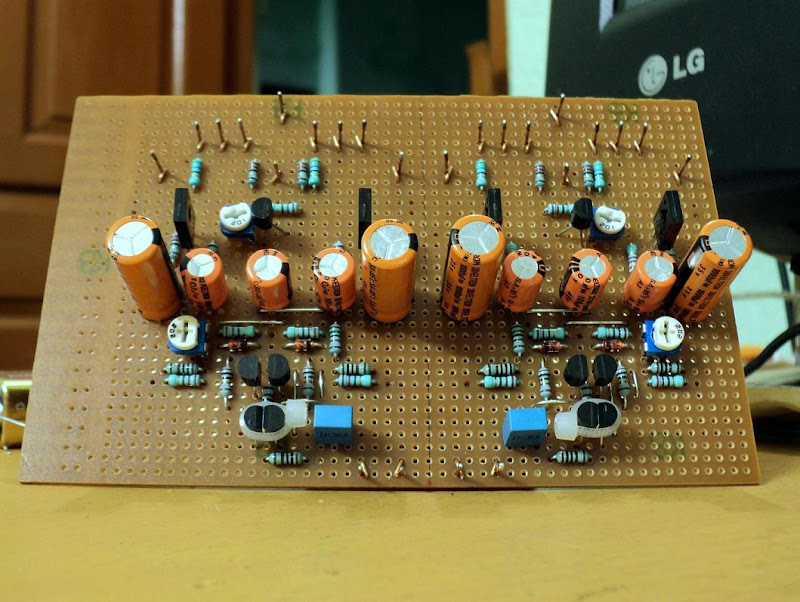

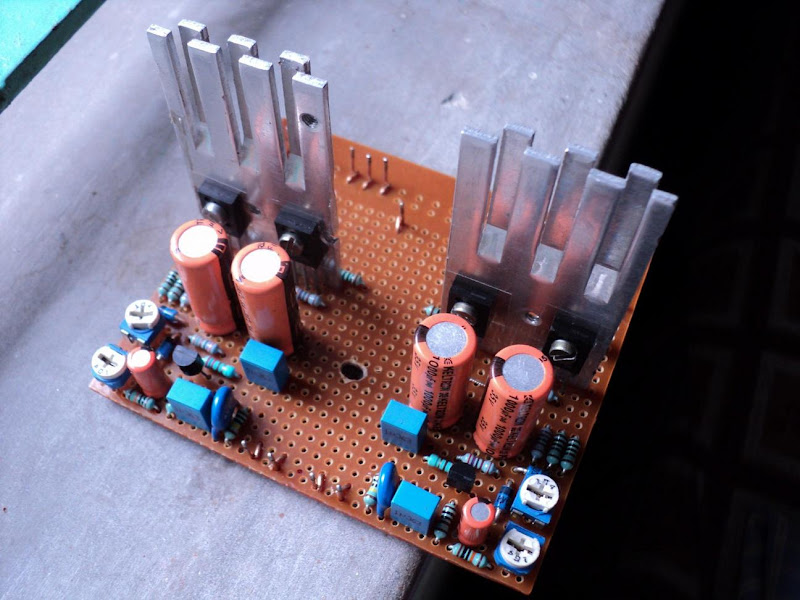

First finished stereo Class-A amp with Capacitance multiplier(sold)

Zen-type

SSA Failed Attempt

Micro DOZ

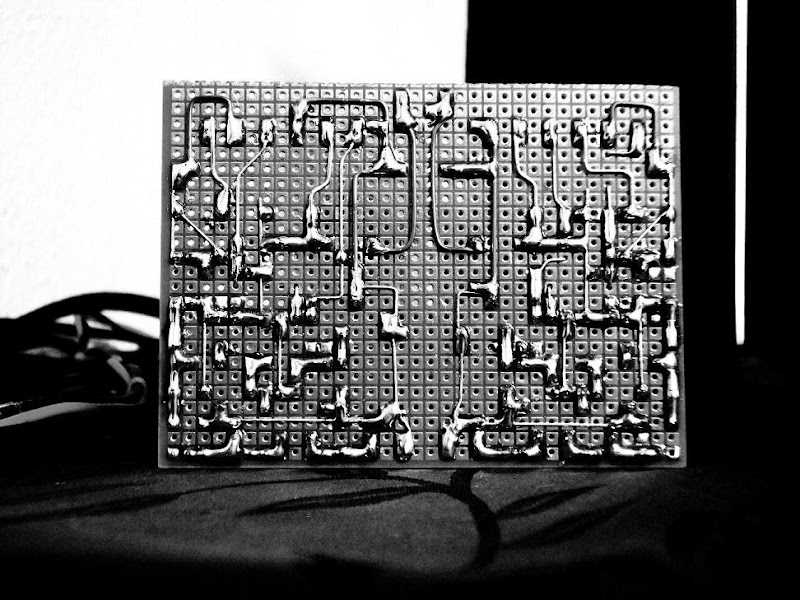

Micro DOZ underside

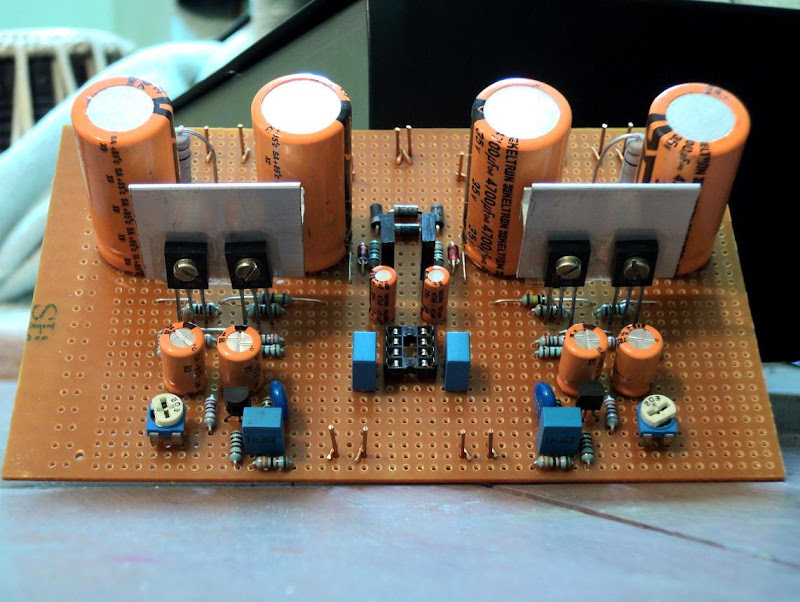

DOZ with DC Servo

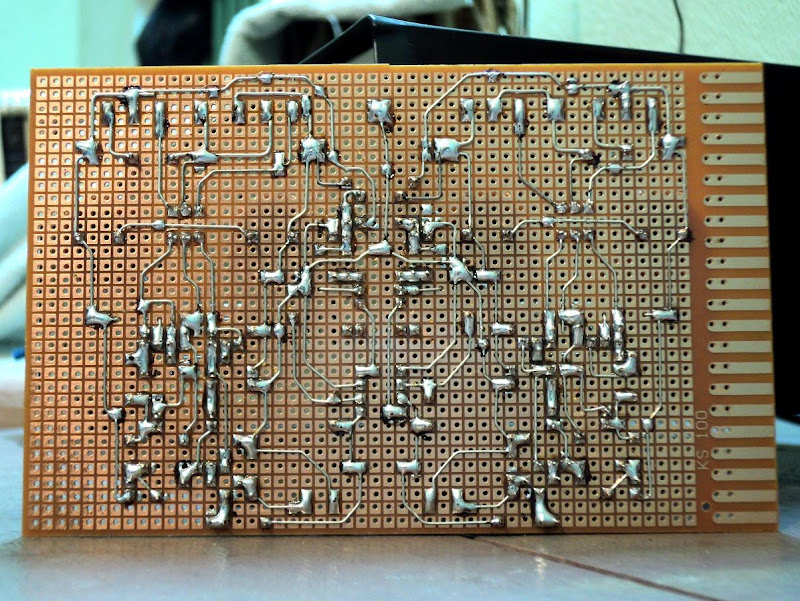

DOZ with DC Servo underside

CMoy 2Watt Cutie Amp

shaan

Old Class-AB quassi-complementary for 2N3055

Pavel Macura's MOSFET Power Follower SE Class-A Source Follower

IRF540 Class-AB Little Monster(Excellent Bass)

LM3886 Chipamp

Guitar Preamplifier with Diode Clipping distortion

Linkwitz-Riley 24dB/octave active crossover

Finished old (and sold) Class-AB amp

2SC5200 quassi-complementary Subwoofer Plate amps

Planning...

ESP P101 Clone(with guessed parts

HEXFET input experimental SE Class-A amp(2 gain stage)

ESP Subwoofer Processor (Small but Magical

ESP Thermo-Fan controller

First finished stereo Class-A amp with Capacitance multiplier(sold)

Zen-type

SSA Failed Attempt

Micro DOZ

Micro DOZ underside

DOZ with DC Servo

DOZ with DC Servo underside

CMoy 2Watt Cutie Amp

shaan

Last edited: