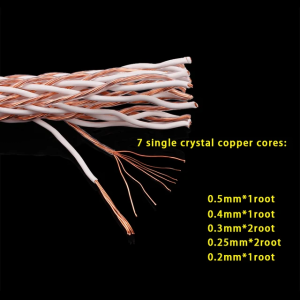

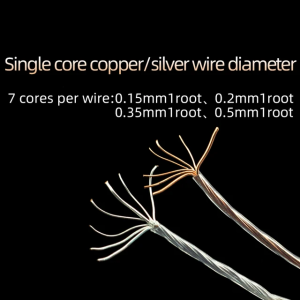

That's a Kimber 12Tc Copy Cable from AliExpress .

Thanks for sharing your view, Not sure if Kimber manufacture their own cable, for accent series. I am sure they take cable from China and get it soldered in USA.

Are these from GR. (Danny) seen a similar one in his YT channel?

No, this is procured from Alibaba.com. Minimum order quantity is 100 Meters. In fact, I saw his DIY cables in the youtube, I was about to buy it, then I ran in to this as this option is very very low on cost.

As I Proceed, want to take a call what terminals should i use in this cable. long back I bought few Brass Spade terminals for 8 AWG cable which is lying around un used. last year I bought Yarbo

Copper banana Plugs and

Copper Spade Connectors from Hificollective.com.

Decided on Yarbo as the Lintons are already upgraded with

Cardas long unplated copper binding posts. Also considered to us the Nylon boots for covering the splitting ends of the cable instead of metal cable splitters which may add more weight.

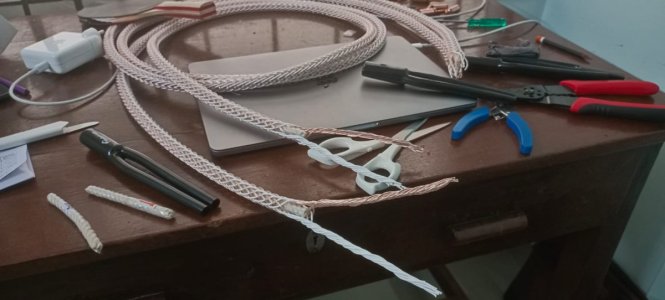

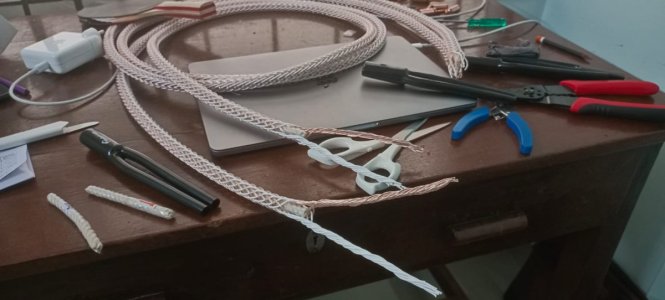

Got this 8MM cradle rope from local store to insert it inside the cable, this will maintain the overall diameter of the cable constant as the raw cable what I got is hollow.

To start pushing the cotton rope in to cable, attached a pen using a 8mm transparent heat shrink.

Secured the joint of pen and rope with 10mm black heat shrink

Started pushing rope through the cable, can see the cable grow fat.

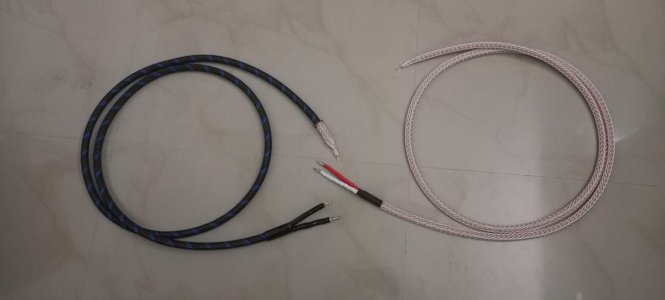

Just a comparison of cable with and without rope.

This is not an easy task to do, But post rope treatment the cable looks better and bulky. I pulled it on bare hands, had the pain on my paws for a week. Recommend to wear a glove for protection. One more thing is the over all length has got reduced to 4.5 meters from 5,5 meters.

Cut the cable in to 2 for left and right and secured the rope with a 8mm heat shrink with direction being marked.

went through the weaving for a required length and straightened the leads of wires.

Twisted the positive and negative leads together

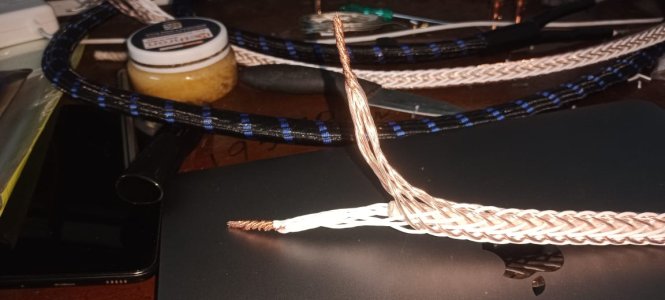

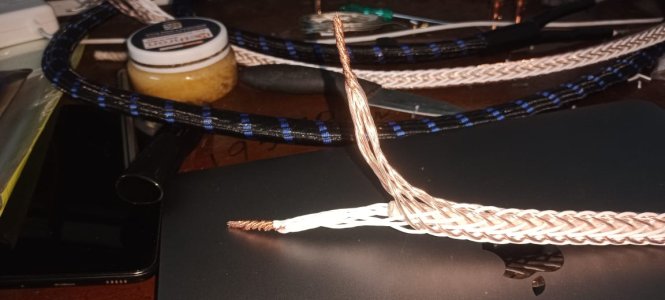

Used a wire striper gently and removed the insulation with hands, Dont want to take a chance wire striper cutting away the leads. Its a pain full task to do it on hands lots of damages on my nails.

Used Mundrof 9% silver and 1% gold soldering lead to solder them together. One solder of a cable took slightly more than a feet mundrof solder. really need a 50W soldering iron to get the melting done on the copper. the cable is insulated with high quality Teflon which helped to withstand the heat. PCV or PE will definitely melt away and deform the cable structure

Put a 8mm red and white heat shrink 2 layers to add thickness and 15 mm black heatshrink on the end of rope.

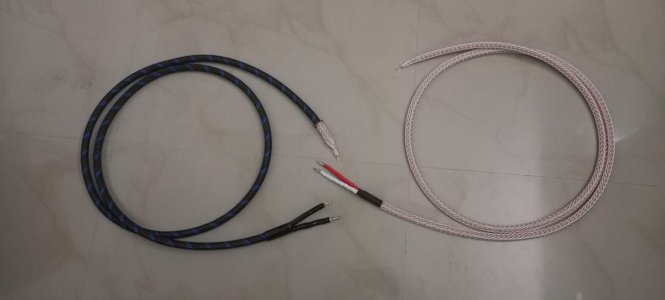

Put the outer sleeving what I have got for this and secured it with a 20MM heat shrink on the rope end, then inserted the nylon Pants.

Did the same for the other ends.

important to apply extra flux to get a better welding