analogadikt

Well-Known Member

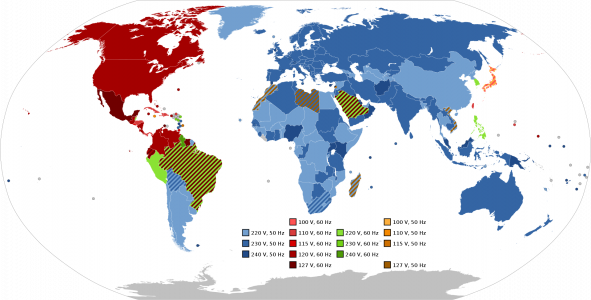

I use several vintage American amps that are 117 volt/60 Hz as per the back plate. I have 1.5 KVA step down that delivers 120V at 50Hz. I face no problems

There are many turntables with A/C motors that can be selected to run at either 110/120 or 220/240 volts. To give give the correct and same platter speed at either 59 or 60 Hz, only the pulley of correct diameter needs to be fitted. The motor has no heating or whatever problem as long as the voltage supplied matches the selected configuration on the motor.

The drill motor overheating problem is most likely due to the step down delivering inadequate current.

The AV receiver circuit runs on DC. There is a rectifier after the transformer secondary that converts the A/C output from the trafo secondary to D/C. The frequency of the A/C supply has no effect on the circuitry.

A previous discussion

www.hifivision.com

www.hifivision.com

Regards,

There are many turntables with A/C motors that can be selected to run at either 110/120 or 220/240 volts. To give give the correct and same platter speed at either 59 or 60 Hz, only the pulley of correct diameter needs to be fitted. The motor has no heating or whatever problem as long as the voltage supplied matches the selected configuration on the motor.

The drill motor overheating problem is most likely due to the step down delivering inadequate current.

The AV receiver circuit runs on DC. There is a rectifier after the transformer secondary that converts the A/C output from the trafo secondary to D/C. The frequency of the A/C supply has no effect on the circuitry.

A previous discussion

Step down transformer for stereo amplifier

Recently purchased a pioneer amplifier sa8900 rated at 110 watts (Japanese market ) obviously from the used market . After buying I read a thread in Hifivision for hum generated from step down transformers . Three questions : 1. Brand to be used for the amplifier in India 2. What KVA rating of...

Regards,

Last edited: