Hi All.

I just completed my first diy 2-way bookshelf speaker project. Please could you share your opinion and what I can do better next time.

I would like to thank FM @arunkvivek for guidance provided.

Have been looking for a project to build for some time. I got an idea after I came across the post in ASR.

www.audiosciencereview.com

The above driver is still being manufactured in India (by Peerless Audio which is currently not related to Peerless Fabrikkerne but bought over assets of peerless's Indian subsidiary)

www.audiosciencereview.com

The above driver is still being manufactured in India (by Peerless Audio which is currently not related to Peerless Fabrikkerne but bought over assets of peerless's Indian subsidiary)

diyaudiocart.com

diyaudiocart.com

Then came found another tweeter from peerless which was apparently used by the Energy Connoisseur series.

https://electrocarts.in/product/25mm-silk-dome-tweeter-low-fs-neo-system/

That's how project code name Alpha/Energy was conceived.

1. I started by measuring the TS parameters myself by using test jig (https://audiojudgement.com/measure-thiele-small-parameters-using-free-software/)

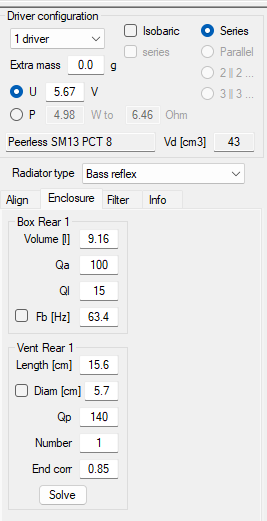

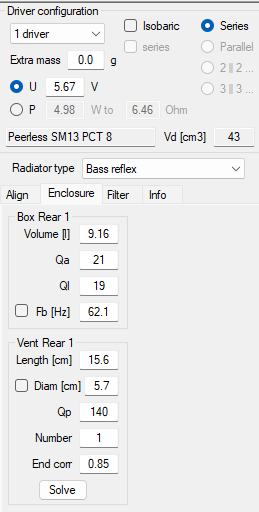

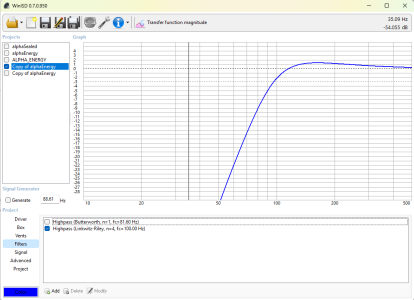

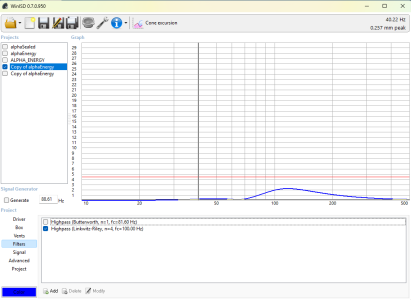

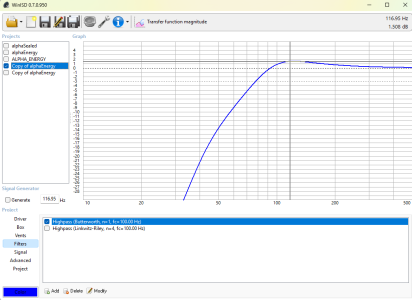

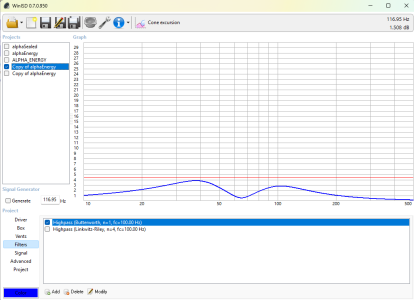

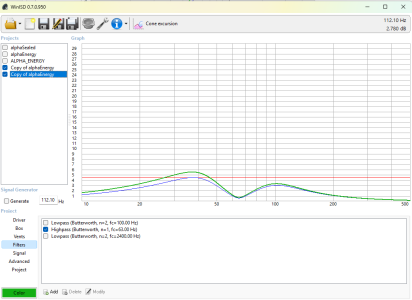

2. Then designed enclosure in WinIsd . The volume is approx. 9.14 liters with port diameter 2.25 inches, port length 6.2 inches tuned to 65hz

Enclosure was built using 18mm HDF wood which was scraps found at local CNC shop.

Dimensions are 7.5W x 10D x 13H inches.

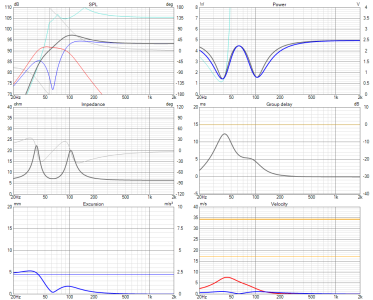

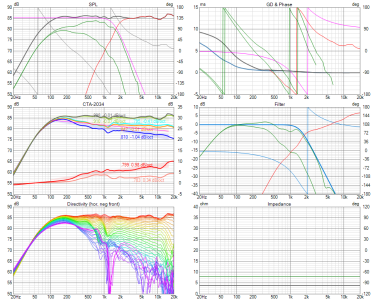

3. Measured the Drivers in box and captured FRD and ZMA. I also captured the woofer in different axis's to find cone breakup. Used Dayton imm-6 mic.

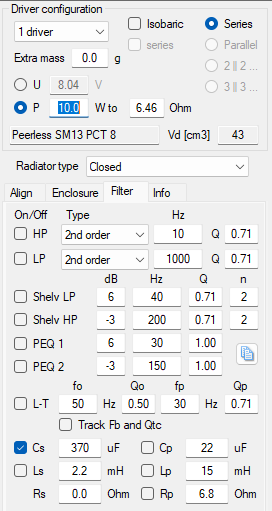

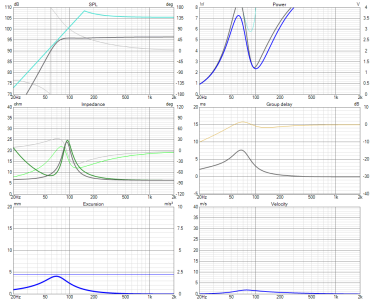

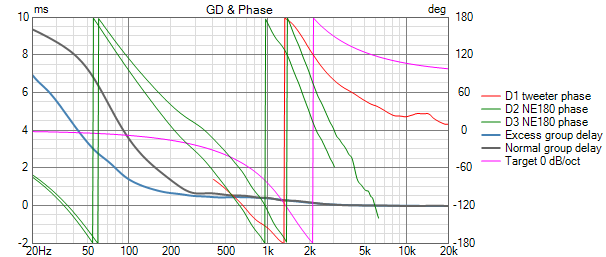

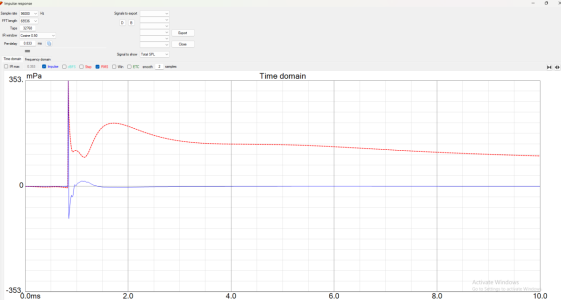

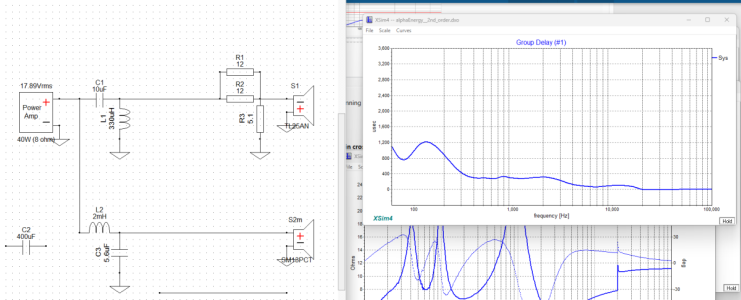

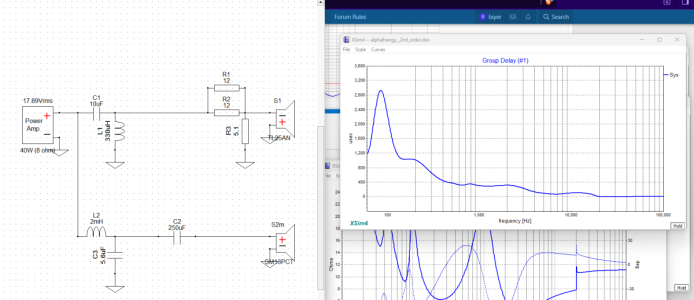

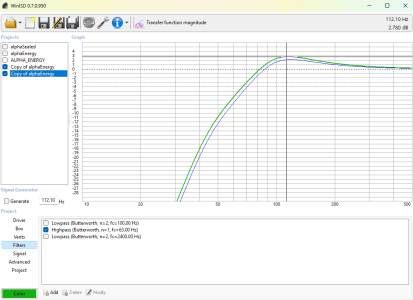

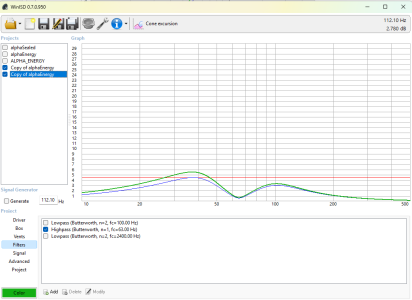

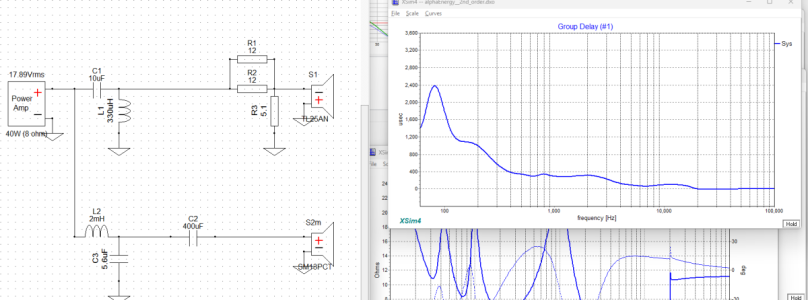

4. Used xsim to design crossover.

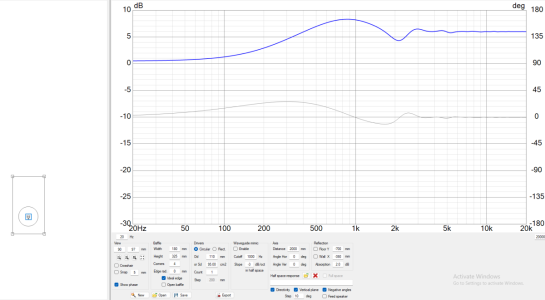

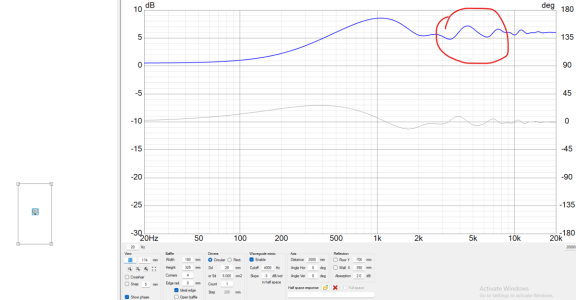

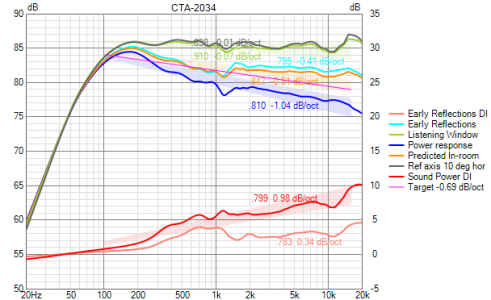

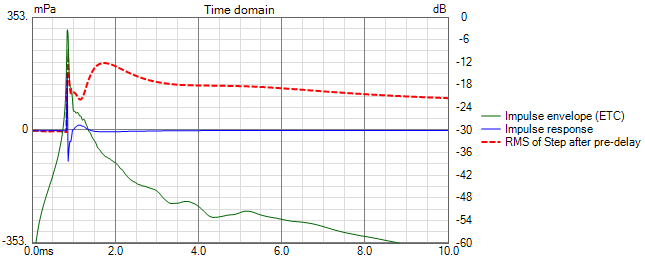

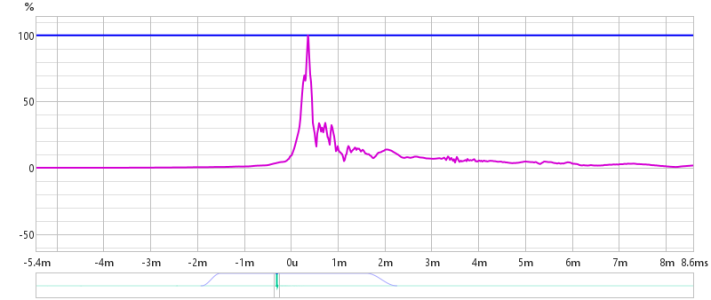

5. Put everything together and measured the response (All measurements are with 1/48th smoothing and 5db step size)

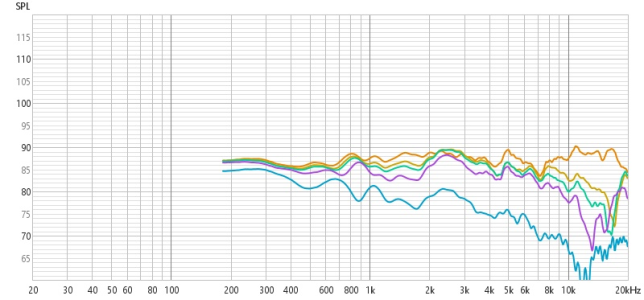

On axis 30.40.60 and 90 degree response

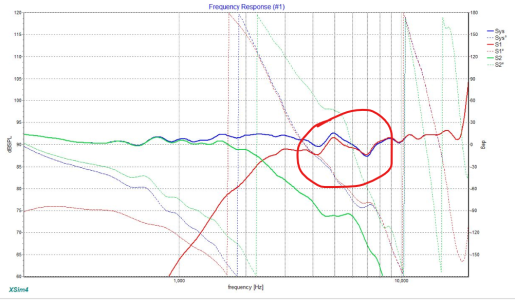

Near Field port (RED) , Woofer (BLUE) and Tweeter (GREEN)

the cabinet/ port resonance around 800hz needs to be addressed. Also need to measure with mic closer next time.

Pics

Finished Painting using Granotone Speaker Paint.

The Total Cost of project was under 17000 INR

Overall I am very happy with the project. They sound better than my Wharfedale Diamond 9.2. I am caught up with some family responsibilities will add additional measurements once I find time.

I am currently powering these using a TDA1521 board based audio amplifier which I built for testing.

I just completed my first diy 2-way bookshelf speaker project. Please could you share your opinion and what I can do better next time.

I would like to thank FM @arunkvivek for guidance provided.

Have been looking for a project to build for some time. I got an idea after I came across the post in ASR.

Disassembly of psb Alpha B1 bookshelf speakers

It's cold and windy outside, I'm bored, my hands are itching to do something, so here I am. The psb Alpha B1 are my first "decent" speakers, purchased at a retail price of $299 CAD/pr. Needless to say that I have long outgrown them in the ten years since, and I'm fed up with trying to offload...

www.audiosciencereview.com

www.audiosciencereview.com

Peerless SM13-PCT-8 5.25" Hi-Fi Woofer Titanium Coated PP

Peerless SM13-PCT-8 5.25" Hi-Fi Woofer Titanium Coated PP Overview: This 5.25 inch 8 ohm driver is a member of the high performance HDA (High DefinitiThen came found another tweeter from peerless which was apparently used by the Energy Connoisseur series.

https://electrocarts.in/product/25mm-silk-dome-tweeter-low-fs-neo-system/

That's how project code name Alpha/Energy was conceived.

1. I started by measuring the TS parameters myself by using test jig (https://audiojudgement.com/measure-thiele-small-parameters-using-free-software/)

2. Then designed enclosure in WinIsd . The volume is approx. 9.14 liters with port diameter 2.25 inches, port length 6.2 inches tuned to 65hz

Enclosure was built using 18mm HDF wood which was scraps found at local CNC shop.

Dimensions are 7.5W x 10D x 13H inches.

3. Measured the Drivers in box and captured FRD and ZMA. I also captured the woofer in different axis's to find cone breakup. Used Dayton imm-6 mic.

4. Used xsim to design crossover.

5. Put everything together and measured the response (All measurements are with 1/48th smoothing and 5db step size)

On axis 30.40.60 and 90 degree response

Near Field port (RED) , Woofer (BLUE) and Tweeter (GREEN)

the cabinet/ port resonance around 800hz needs to be addressed. Also need to measure with mic closer next time.

Pics

Finished Painting using Granotone Speaker Paint.

The Total Cost of project was under 17000 INR

Overall I am very happy with the project. They sound better than my Wharfedale Diamond 9.2. I am caught up with some family responsibilities will add additional measurements once I find time.

I am currently powering these using a TDA1521 board based audio amplifier which I built for testing.

Last edited: