Hi,

After experimenting with DIY RCA cable last week, I decided to try making a power cable. The off- the shelf cables seemed too expensive and given the divided opinions I wasnt willing to dive head down. Gene of Audiohollics calls it snake oil however some of the other "experts" seemed to say that power cables matter such as Paul (PS Audio), Audiophiliac, GR Research, etc. While I had dismissed the whole "cable" thing as snake oil in the past, I had a different experience after moving to Belden speaker cables and then the DIY RCA. Perhaps I had moved to more evolving speakers by then, allowing me to notice differences. Perhaps the differences were due to material rather than brand or braiding or anything else- tin vs copper.

I picked up a 2 meter Aucharm power cable from TheAudiocrafts along with "audiophile" copper coated US type plugs. The whole package cost me ~ INR 4,700 and was delivered in 24 hrs by DTDC Air.

The first impression of the cable was how thick it was- see pic

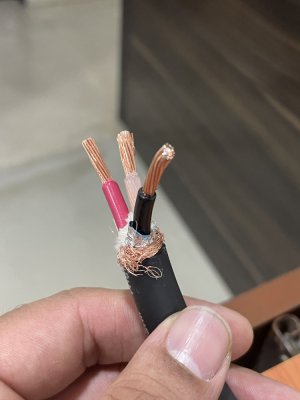

The cable itself is very well made with proper shielding and insulation- see pic.

Opening the cable with my cheap wire cutter was surprisingly okay- the copper strands and overall thickness was impressive.

The "audiophile" power plugs also seem very well made (copper & US type)

However getting the cable into the plug was nightmarish. Being in all 3 holes at the same time seemed impossible at first and really tested my patience.

After struggling for 1/2 hour I finally managed the impossible. I haven't used any insulation tape yet.

Attached the cable to my Rotel and it worked in first attempt

Listening test:

I seemed to notice more background details in 2 songs- perhaps I was paying more attention this time. My wife and daughter did not notice any difference . But they are not audiophiles- they just enjoy the music-details or no details.

. But they are not audiophiles- they just enjoy the music-details or no details.

However I am happy to have experimented with the power chord and will listen for more details as the wire "breaks-in" over the next few days.

Thanks for reading- suggestions welcome.

After experimenting with DIY RCA cable last week, I decided to try making a power cable. The off- the shelf cables seemed too expensive and given the divided opinions I wasnt willing to dive head down. Gene of Audiohollics calls it snake oil however some of the other "experts" seemed to say that power cables matter such as Paul (PS Audio), Audiophiliac, GR Research, etc. While I had dismissed the whole "cable" thing as snake oil in the past, I had a different experience after moving to Belden speaker cables and then the DIY RCA. Perhaps I had moved to more evolving speakers by then, allowing me to notice differences. Perhaps the differences were due to material rather than brand or braiding or anything else- tin vs copper.

I picked up a 2 meter Aucharm power cable from TheAudiocrafts along with "audiophile" copper coated US type plugs. The whole package cost me ~ INR 4,700 and was delivered in 24 hrs by DTDC Air.

The first impression of the cable was how thick it was- see pic

The cable itself is very well made with proper shielding and insulation- see pic.

Opening the cable with my cheap wire cutter was surprisingly okay- the copper strands and overall thickness was impressive.

The "audiophile" power plugs also seem very well made (copper & US type)

However getting the cable into the plug was nightmarish. Being in all 3 holes at the same time seemed impossible at first and really tested my patience.

After struggling for 1/2 hour I finally managed the impossible. I haven't used any insulation tape yet.

Attached the cable to my Rotel and it worked in first attempt

Listening test:

I seemed to notice more background details in 2 songs- perhaps I was paying more attention this time. My wife and daughter did not notice any difference

However I am happy to have experimented with the power chord and will listen for more details as the wire "breaks-in" over the next few days.

Thanks for reading- suggestions welcome.

Attachments

Last edited: