reubensm

Well-Known Member

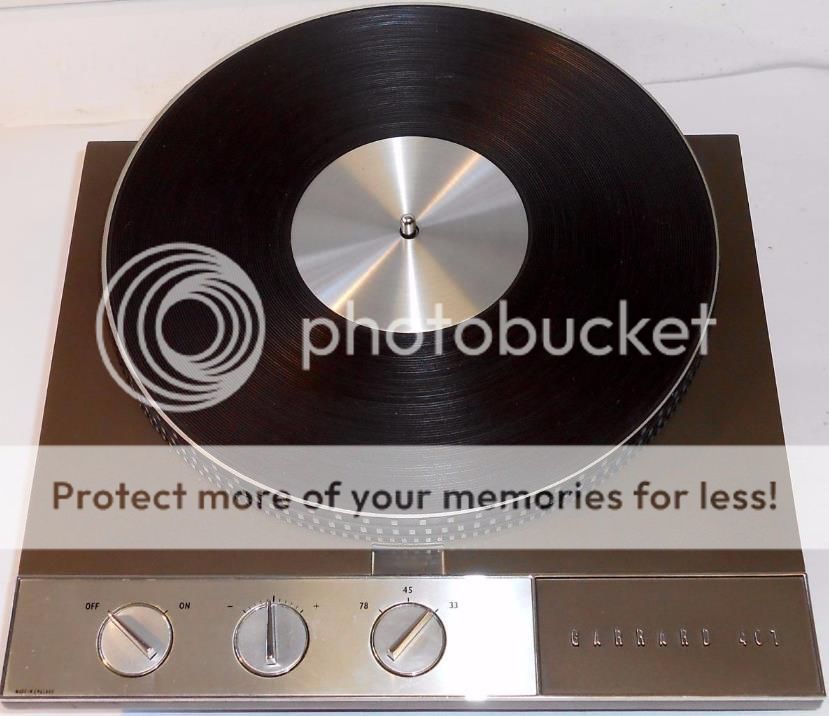

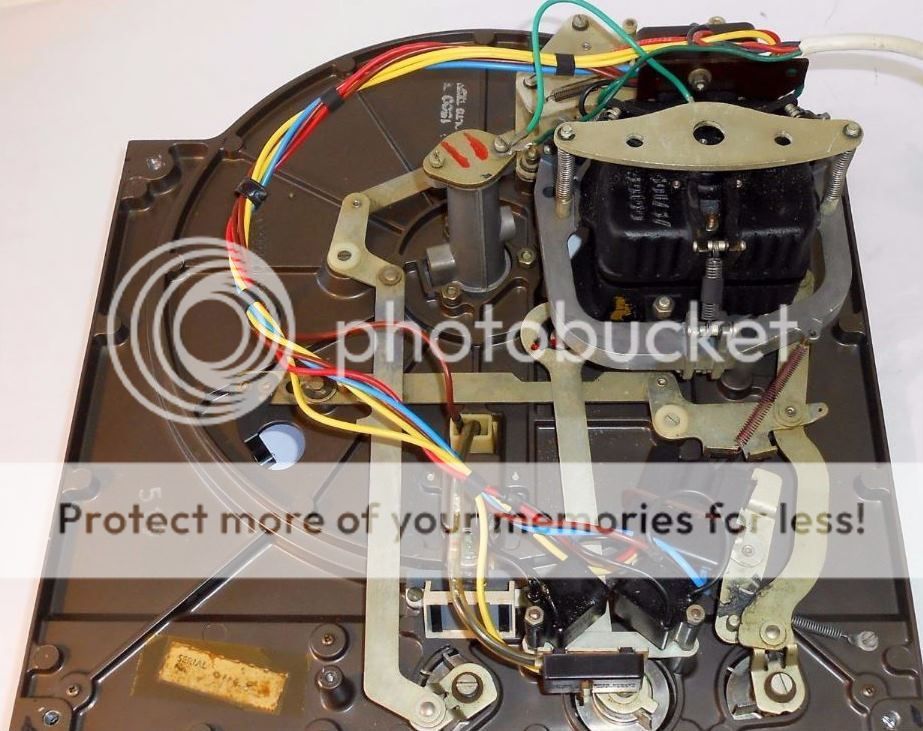

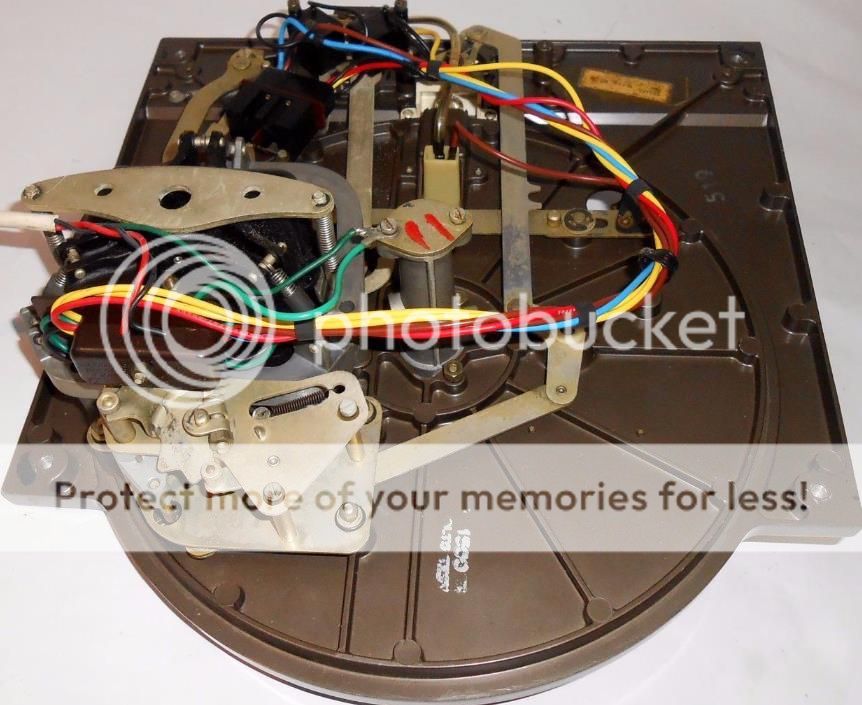

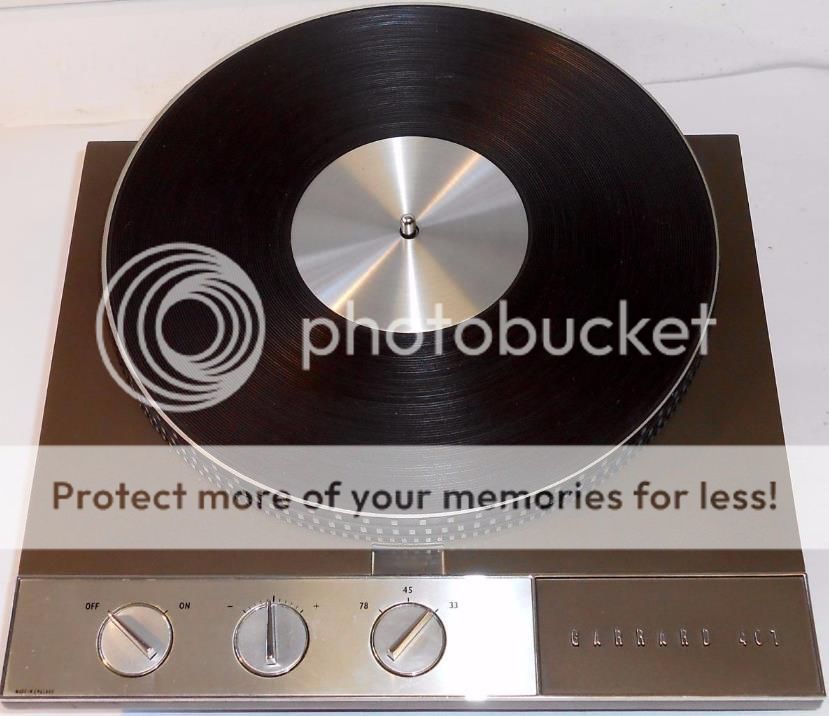

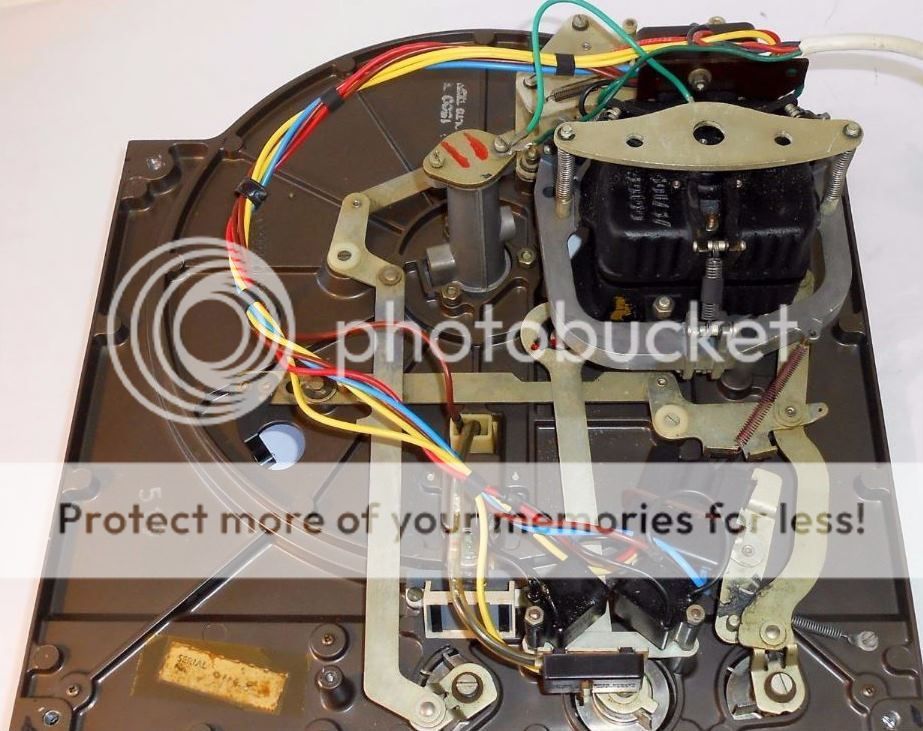

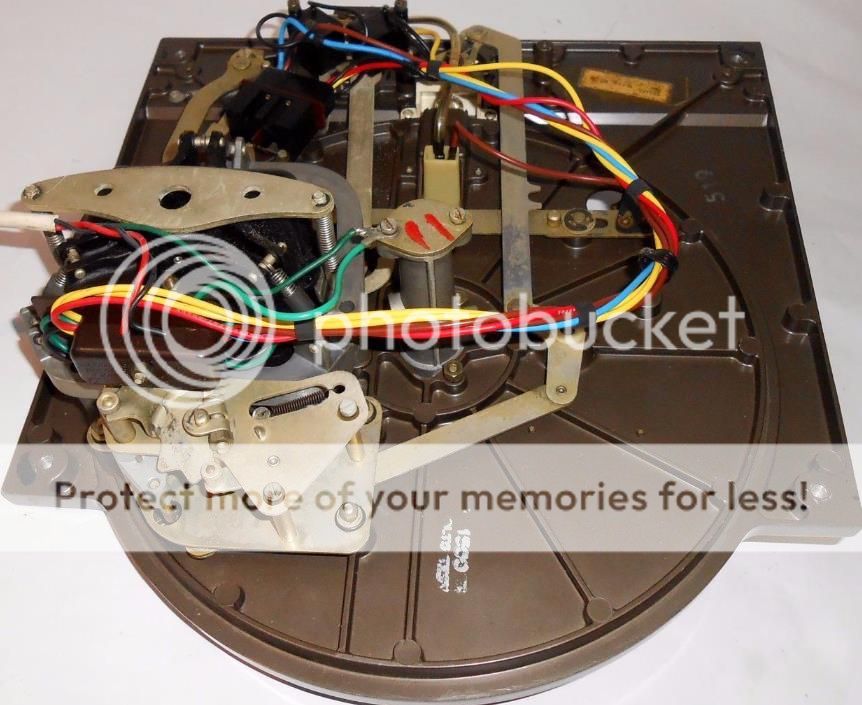

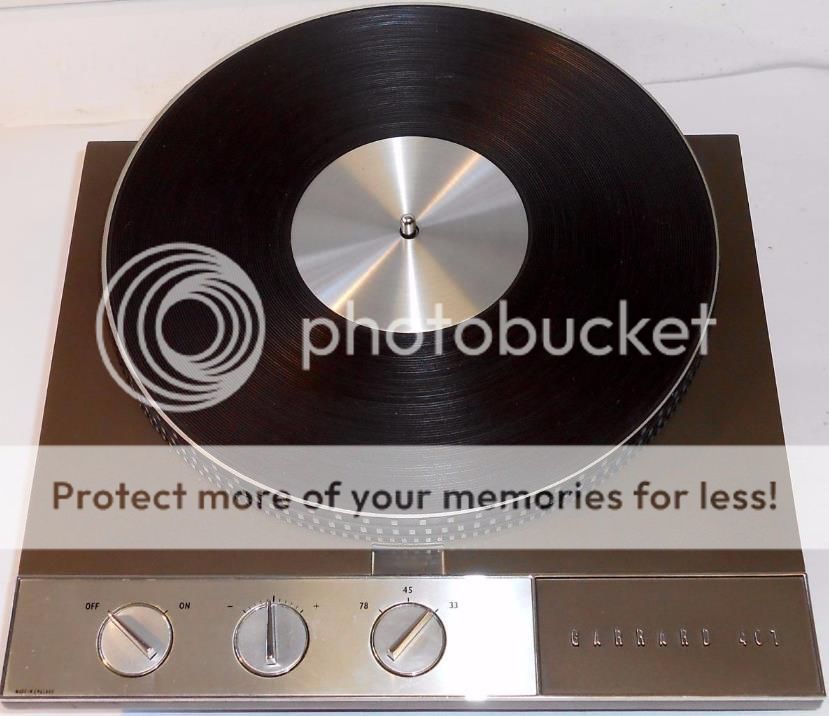

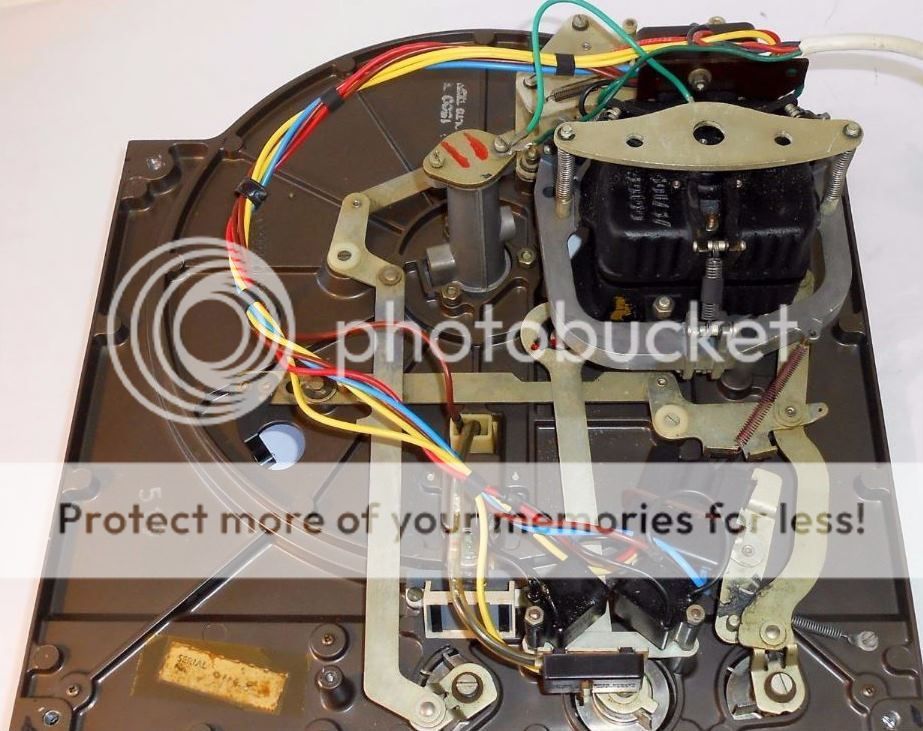

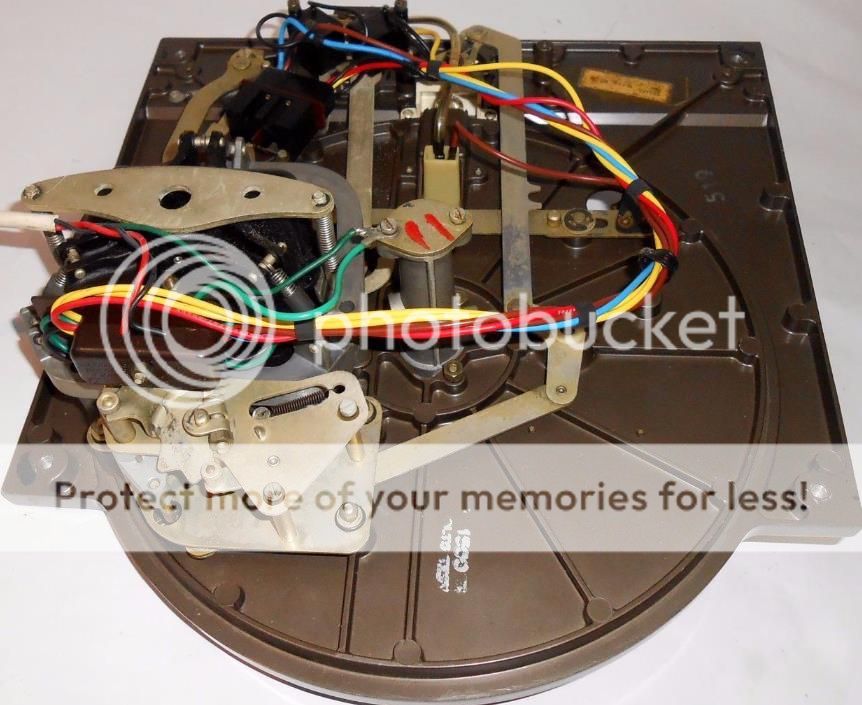

Some pictures of my very early model 401 which I located on my PC, thought I'll share them.

Do any of you Garrard owners hear rumble on your TT while playing ?

Isn't rumble part of design criteria for this TTthen you end up making a multilayer plinth to eliminate it!

Do any of you Garrard owners hear rumble on your TT while playing ?

Whenever I have heard a 301 play, when the bass control was turned up, there was slight audible rumble, even when using the Loricraft sliced golf-ball plinth

and now I am running a moderately done up Garrard 301 (oil bearing).

Isnt it true that the most appropriate way of handling rumble is mass ? [/url]

Definitely a problem. Anothe vibration zone. The washers below the top screws serve to absorb resonaces. It would also be good to add washers (or gaskets ) between the nuts and the underside of the plinth. Don't over tighten the nuts tho'. A nice firm fit would probably get the best results.

I noticed that he had very thin rubber sheets sandwiched between each of the layers.

My 301 is bolted without washers. Can you suggest the material to use for washers. Also my 301's OEM screw-heads are a bit old-looking. Was planning to upgrade them to newer ones. Any suggestions.