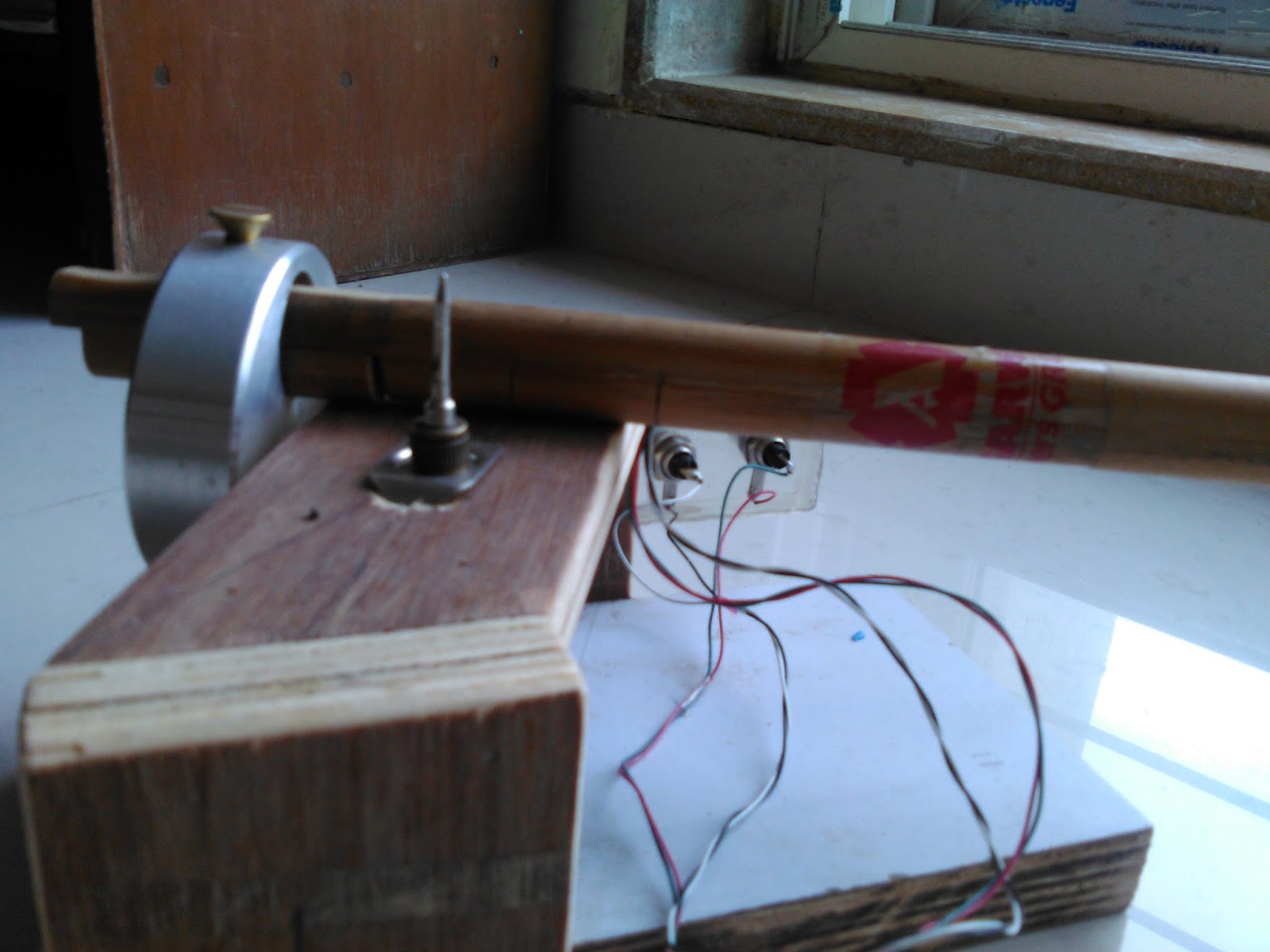

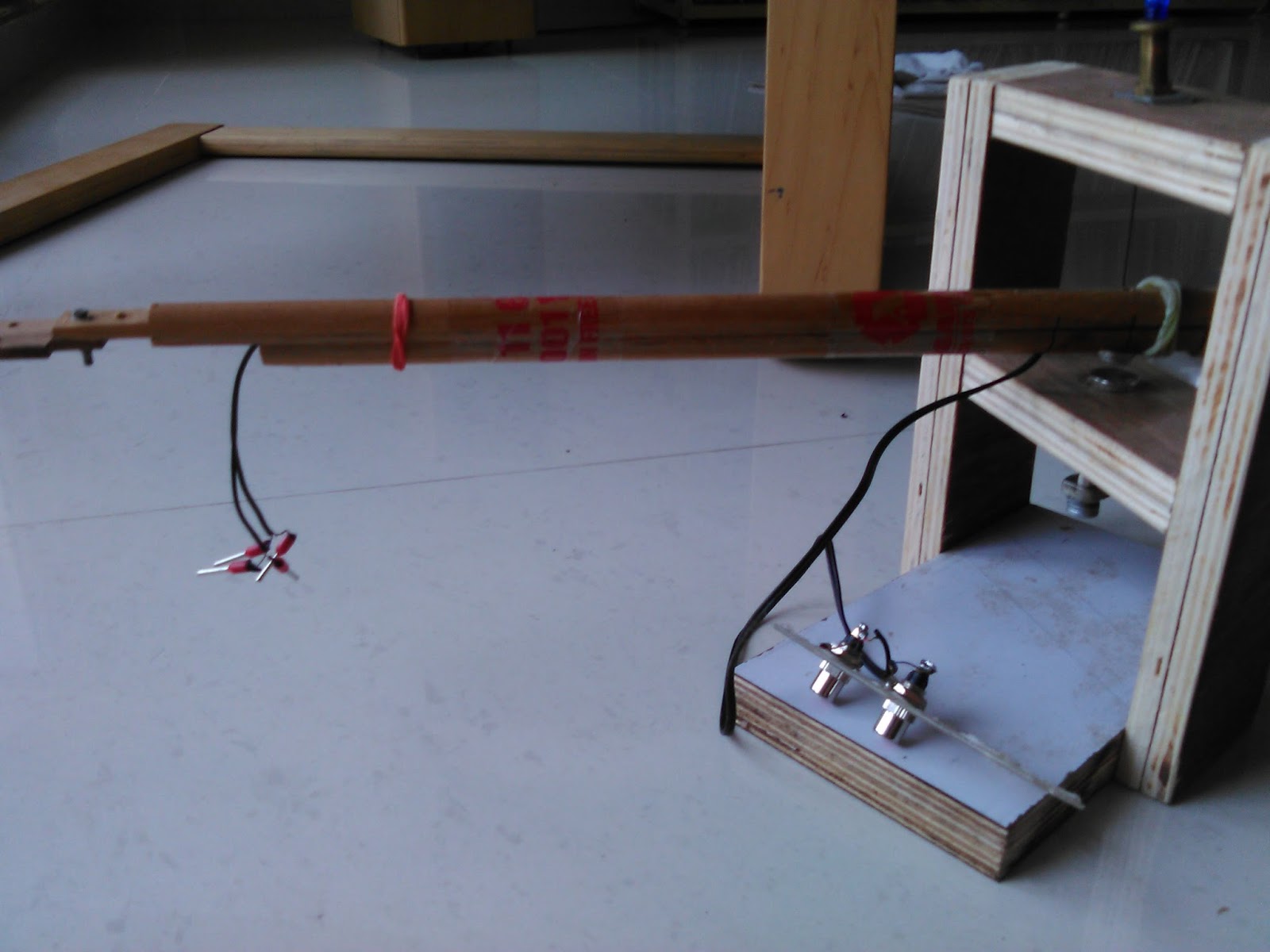

Seeing JLS001's wonderful, simple, effective uni pivot tone arm, making one of my own was going in my mind.

In addition to enjoying life of a diy cycle, another arm will help me having to cart-stylus ready for different kind of records (condition). Learning through it is a basic gain anyway.

I read Joshua's posts several times but missed mentioned topic about Frank Schroeder's unique magnet bearing unipivot kind of tone arm design. Once I stumbled that topic while re-reading Joshua's post, I read diyaudio's related post DIY Schroeder Tonearm??? - diyAudio.

For picking up interest faster, go to page 40 and see photos.

Knowing making of Schroeder type require tenacity, good tools, knowledge and huge time, I just could not take off my eyes and mind for its simplicity and beauty in its design.

I want to make it as simple as possible. I know I will loose accuracy if I am too simple, but I still want to try.

Not that I understood all posts (984 in total) in it, but most and while reading towards the 3/4 post of it, a thought strike me.

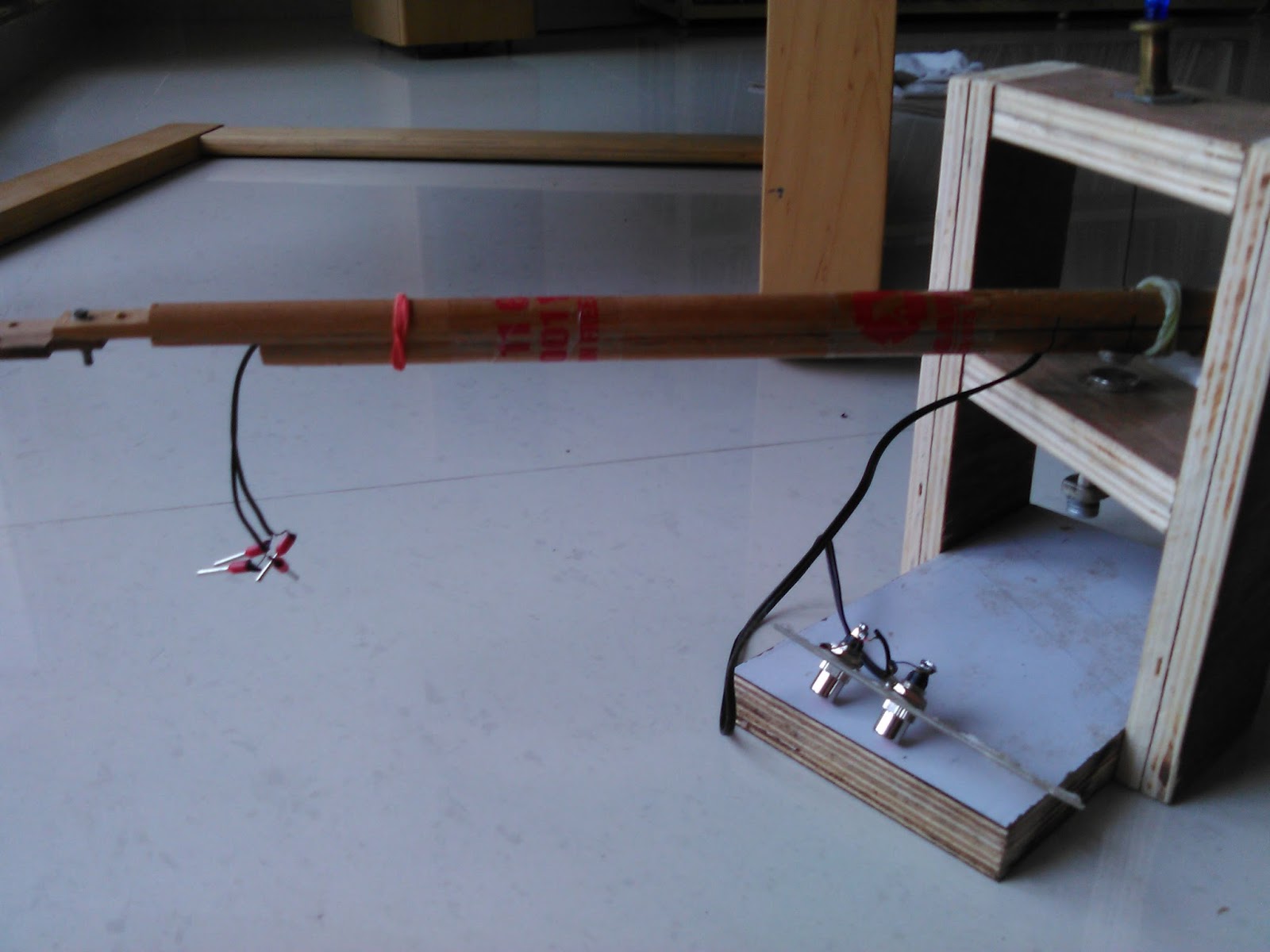

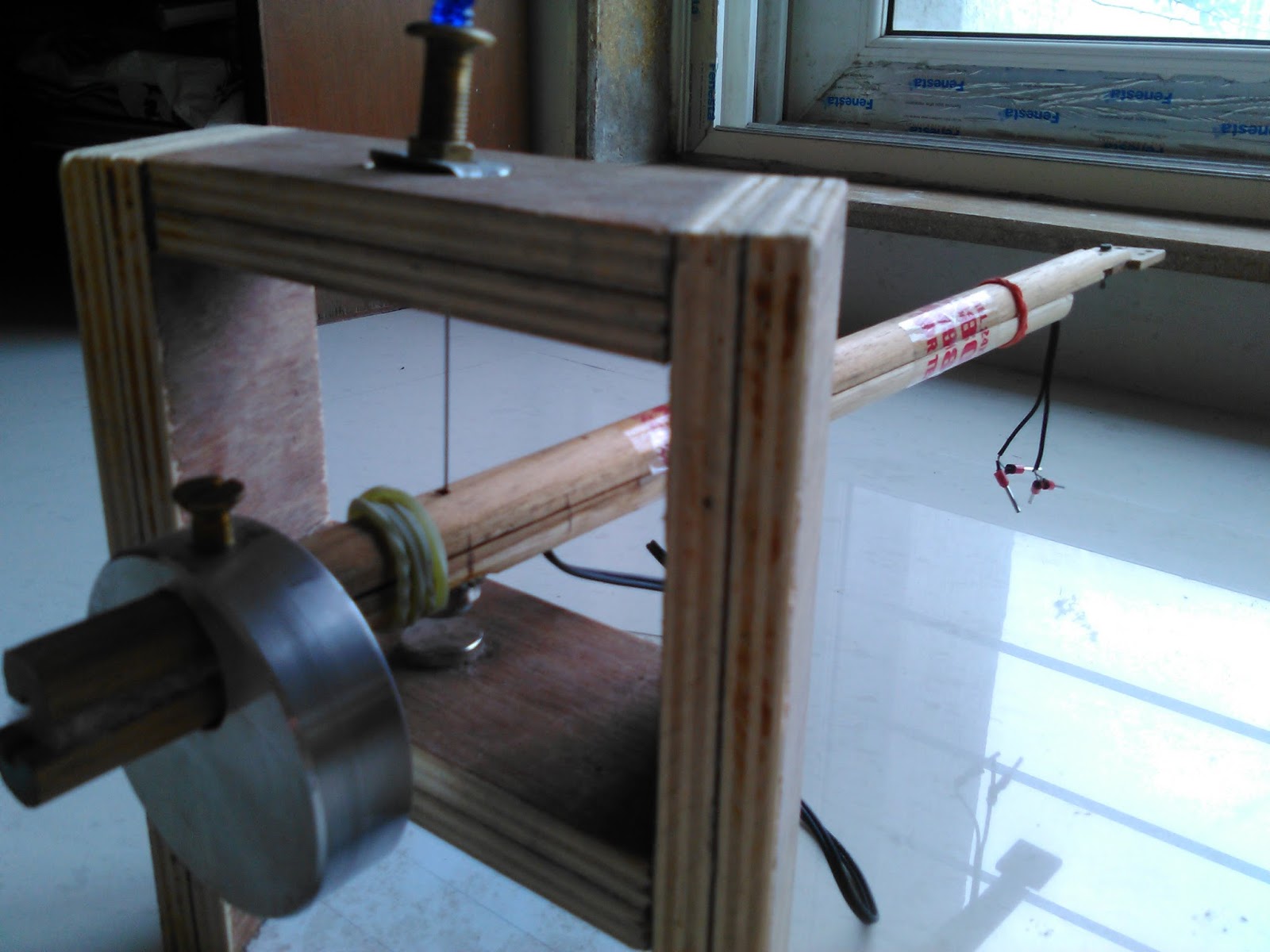

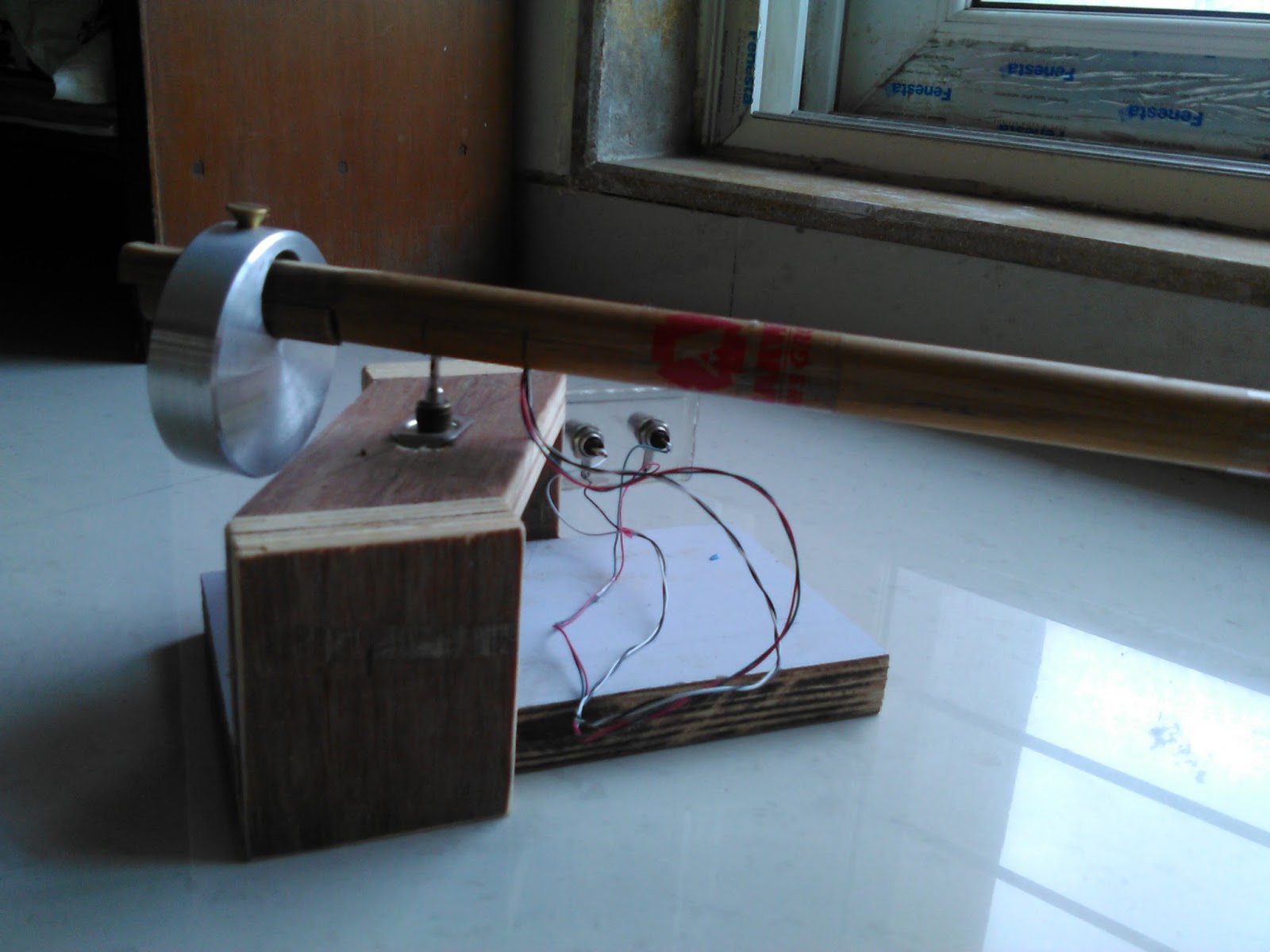

What if I replace those two magnets by a rubber band below the wand, but keep all other design identical. Magnet attracting each other in Schroeder's design provides the damping and bearing. But in case of feedback (movement)coming from records via stylus moves magnet in wand away from magnet on baseplate. This movement actually increase gap between centre point on magnet surfaces and hence decreases attraction force.

But, if I put rubber band instead, any movement will increase pull in the rubber band so, it should work better. Am I missing or mis understanding something?

I know a rubber band or a rubber string will induce more friction than free air magnets but if I am right in assuming rubber band works better or equal in terms of damping and tension force, friction can be a workable compromise as the design will be much simpler than uni-pivot (may be).

And hooking a rubber band will not infer much noise I think.

Design drawing is still in my head, will come to paper soon.

I want to make such a design which can try my idea first and then go for Schroeder clone if I fail.

I will update you all from then on.

Till then give your suggestions/comments/ideas.

In addition to enjoying life of a diy cycle, another arm will help me having to cart-stylus ready for different kind of records (condition). Learning through it is a basic gain anyway.

I read Joshua's posts several times but missed mentioned topic about Frank Schroeder's unique magnet bearing unipivot kind of tone arm design. Once I stumbled that topic while re-reading Joshua's post, I read diyaudio's related post DIY Schroeder Tonearm??? - diyAudio.

For picking up interest faster, go to page 40 and see photos.

Knowing making of Schroeder type require tenacity, good tools, knowledge and huge time, I just could not take off my eyes and mind for its simplicity and beauty in its design.

I want to make it as simple as possible. I know I will loose accuracy if I am too simple, but I still want to try.

Not that I understood all posts (984 in total) in it, but most and while reading towards the 3/4 post of it, a thought strike me.

What if I replace those two magnets by a rubber band below the wand, but keep all other design identical. Magnet attracting each other in Schroeder's design provides the damping and bearing. But in case of feedback (movement)coming from records via stylus moves magnet in wand away from magnet on baseplate. This movement actually increase gap between centre point on magnet surfaces and hence decreases attraction force.

But, if I put rubber band instead, any movement will increase pull in the rubber band so, it should work better. Am I missing or mis understanding something?

I know a rubber band or a rubber string will induce more friction than free air magnets but if I am right in assuming rubber band works better or equal in terms of damping and tension force, friction can be a workable compromise as the design will be much simpler than uni-pivot (may be).

And hooking a rubber band will not infer much noise I think.

Design drawing is still in my head, will come to paper soon.

I want to make such a design which can try my idea first and then go for Schroeder clone if I fail.

I will update you all from then on.

Till then give your suggestions/comments/ideas.