When turning the equipment in for repairs, good to keep the following notes in mind:

1) Protection mode in an amp is like us getting a fever. When it comes to fever, the reason can be as simple as a weather change or something more serious. The amp can go into protection mode if there is a simple dry solder in a key area or a variety of reasons leading up to major component failure. Only a skilled technician who has component level repair competence (not the modern PCB replacers

) and is familiar with the amplifier's design philosophy, should take a look.

2) Component level diagnosis and repair is done using a checklist (in the mind, gained out of experience). Its just as how pilots use checklists for various duties that they perform when flying aircraft. If a checklist is not followed, successful repair is almost never achieved or sometimes partially achieved with some possible future consequences.

3) Protection faults provide any knowledgeable mech, an easy opportunity for looting the customer. The fault can be something simple but made to look very difficult which requires exorbitant repair costs

4) When this issue comes up, spot fixing will never sort out the issue completely. The mech will have to do an inside-out check of the amp as the reasons can easily crop up again and cause the amp to fail after a few hours working

5) After coming back from the mech when a protection issue is addressed, the amp has to be stress tested or simply can be left to run for long durations, say 12 hours at moderate listening levels, fully cooled down for about 12 hours and made to run again for another 12 hours. If anything is to come up again, you will definitely find out.

6) Techs when working on amps with switch mode power supplies commonly diagnose the power transformer as faulty. The chances are extremely rare so if your tech tells you this, request that he returns the amp immediately without doing anything on it. The amp with a replaced or rewound power transformer will continue to fail unless the original transformer was failing badly (for which you would have definitely noticed physical signs like smell of something burning, transformer getting unusually hot, etc)

7) Once a protection issue is resolved (depending on what the root cause is), it is always better to recalibrate the amp to factory specs.

Some common (not exhaustive) reasons for amps going into protection mode are:

External circumstances (within the user's control)

- Shorted speakers, or running speaker impedance configurations below 4 ohms (common these days especially with so many DIY speakers around) faulty speaker cross-overs. In some cases, especially with very high power amplifiers, speaker load is a key factor and open circuit in speaker wiring can also trigger the protection circuitry

- Amplifier overheating due to lack of proper ventilation or cooling, especially when running at high levels

- Some liquid spilling on the top of the amplifier and seeping in

- Using amplifiers with switch mode power supplies, with UPS (avoid all, especially UPS which are not True Sine Wave types) or portable gensets

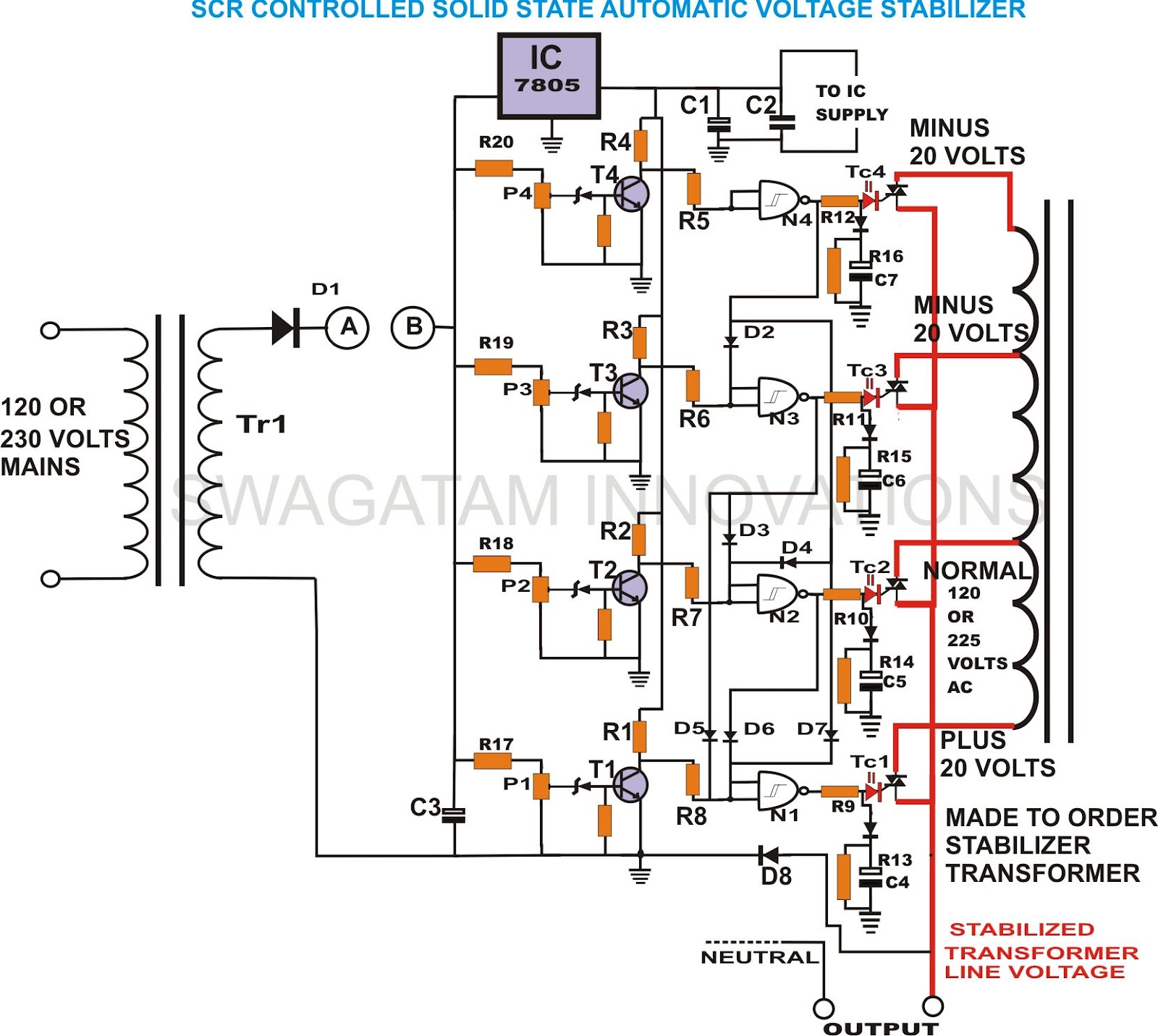

- Using amplifiers with switch mode power supplies, with voltage stabilizers (especially the older ones that are not reliable)

- Using amplifiers with switch mode power supplies with an unreliable electricity supply with voltage fluctuations and spikes, sparking power sockets with loose contacts can damage the amplifier's powersupply. Always use tight fitting mains plugs, preferably 3-way as they tend to fit and hold on very well in addition to being safer

Internal circumstances (should be analyzed and repaired only by a knowledgeable mech)

- Dry solder, especially in the power supply and power amplifier sections

- Microscopic PCB fracture (can happen due to multiple reasons and not just physical abuse)

- Electrolytic capacitor failure in the Power Supply and Power amplifier stages (these are the most stressed components during an amplifier's running). Faulty capacitors don't always display physical damage and hence, should be checked with a capacitance and ESR meter even if they appear physically intact

- Blown resistors - yes, its not always that a blown resistor looks darkened or broken. Faulty resistors may at times function with incorrect impedance. This instance is very rare but extremely difficult to diagnose.

- Blown semiconductors - transistors, integrated circuits, thyristors, and diodes (both rectifier and signal types). And yes diodes, these are often ignored when troubleshooting.

- Amplifier losing its idle current and bias calibration (due to various reasons which have to be diagnosed separately). Component failure in the power amplifier section or components that may be partially functional and on the verge of failing, can contribute

- Faulty protection stage, it is common for the protection stage itself to malfunction or in the process of protecting the amp from some other failure outcome, the protection stage at times, sacrifices itself

- Faulty speaker relay (yes these are electromechanical switches and have a life span depending on the quality of relay used)

- Blown fuses - yes i have intentionally put this one last as a blown fuse is an indication of something else going wrong and further investigation is required. If the amp has not been opened before it is likely that it was working with factory-spec fuses and hence, the chances of fuses overheating and blowing are very less (unless the amp was over-driven)

Note: The above is based on my experiences with resolving this issue. There is more to it but these are the common ones. A protection issue is not like final stage cancer. All protection issues can be resolved. However mechs may tell you that the amp's life is over and the amp has to be discarded. Never do this