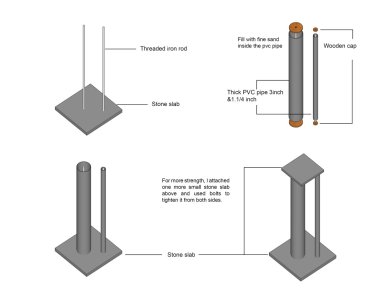

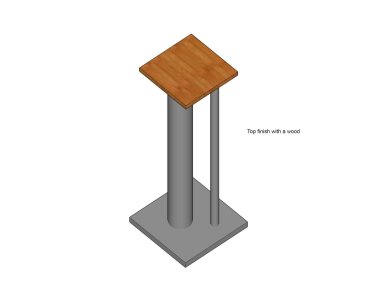

Hey everyone! I have been thinking for many months about sharing pictures and details of my DIY speaker stand. Finally, I uploaded it today. This stand was made by me and my father last year in March, so I have been using it for one year and am very happy. It looks premium and strong from experience. This was very tricky when we made it, and my father helped me do it, and he did the painting job.

Performance and vibration control

I built the stand according to the perfectly maching my ear level from my lisening position. I wanted all long spikes, but due to the height differences, I went for small spikes underneath. I have filled the sand inside and overall improved the sound quality, minimising the impact of vibrations on my speakers by preventing transmission, which results in significantly reduced distortion and coloration. Absolutely; they do the job like branded stands. There are no issues when I play music pretty loud.

(We did it in a cost-effective way and used some materials we already had at home; the rest we brought, and all the tools, including power tools, we already had at home. So if you have some craft skills, anybody can make these pairs.)

Performance and vibration control

I built the stand according to the perfectly maching my ear level from my lisening position. I wanted all long spikes, but due to the height differences, I went for small spikes underneath. I have filled the sand inside and overall improved the sound quality, minimising the impact of vibrations on my speakers by preventing transmission, which results in significantly reduced distortion and coloration. Absolutely; they do the job like branded stands. There are no issues when I play music pretty loud.

(We did it in a cost-effective way and used some materials we already had at home; the rest we brought, and all the tools, including power tools, we already had at home. So if you have some craft skills, anybody can make these pairs.)