I am planning to build speaker stands for Elac Debut BS6.2

I will be using mild steel and the hollow centre column will be filled with sand.

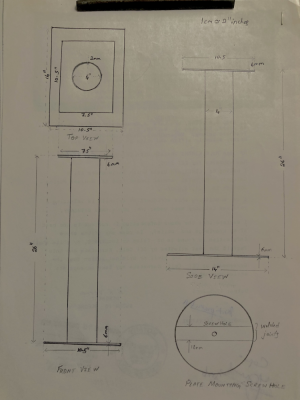

The design is simple. Apart from accounting for a low centre of gravity, I haven't really put efforts in finding out the acoustic properties of the material being used.

The approximate weight would be around 6 kgs per stand (without the sand filling). With my rough calculations, the centre of gravity is at 42% of the height (with speakers and sand filling).

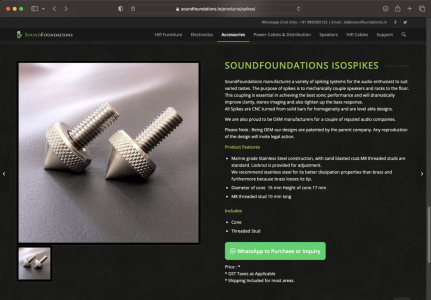

I have not accounted for isolation spikes yet. I still need to read about them. If I go with iso spikes, the height will be cut down to account for the spikes.

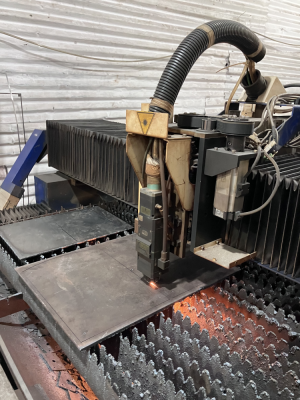

Building it with wood or plywood boards would have been much easier but one of my relative owns a factory with CNC machines. I plan to get the machining done there.

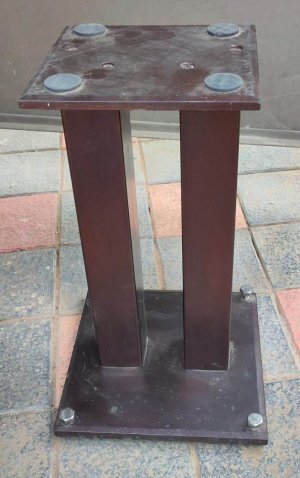

I am attaching a drawing of the proposed speaker stands.

Request your reviews and suggestions.

Thanks in advance.

I will be using mild steel and the hollow centre column will be filled with sand.

The design is simple. Apart from accounting for a low centre of gravity, I haven't really put efforts in finding out the acoustic properties of the material being used.

The approximate weight would be around 6 kgs per stand (without the sand filling). With my rough calculations, the centre of gravity is at 42% of the height (with speakers and sand filling).

I have not accounted for isolation spikes yet. I still need to read about them. If I go with iso spikes, the height will be cut down to account for the spikes.

Building it with wood or plywood boards would have been much easier but one of my relative owns a factory with CNC machines. I plan to get the machining done there.

I am attaching a drawing of the proposed speaker stands.

Request your reviews and suggestions.

Thanks in advance.

Attachments

Last edited: