Audiodoc

Well-Known Member

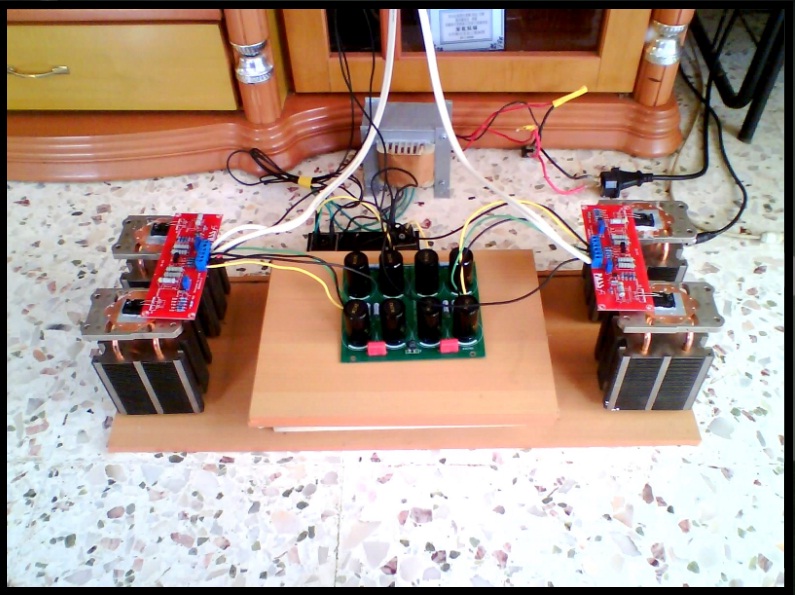

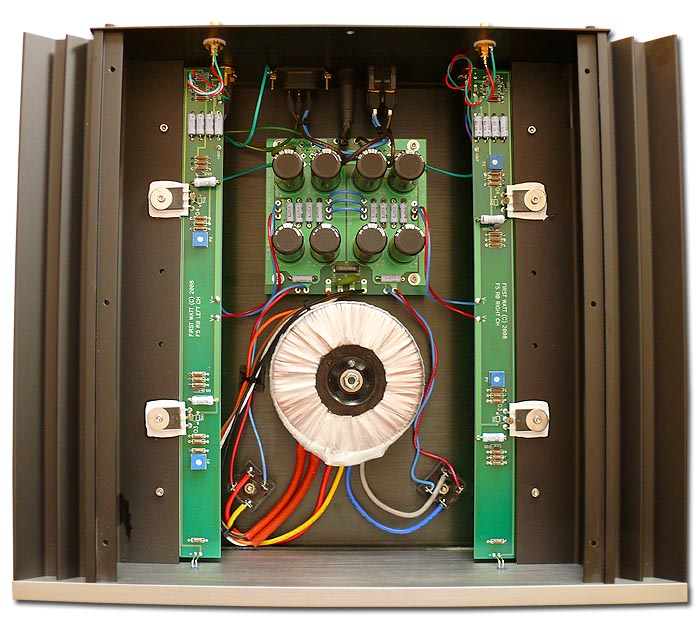

One more advantage is that the CPU coolers tend to have a copper base which conducts heat better that aluminum and have more surface area thereby tending to be more efficient than ordinary heatsinks.

The top and bottom plates can be made of perforated mesh plates which will make the mounting of a 120 mm slow speed or temperature controlled exhaust fan on the top easier and aesthetically pleasing.

Instead of soldering the power transistor/chip directly on the board, we can connect them to the PCB using wires. and those 4 red PCBs can get freedom and be placed elsewhere. It will also allow you to place the 4 heatsinks more conveniently somewhere else as per the design of the casing.

No no no.. This will add oscillations and could self destroy the amp. I have tried in small amp. This huge will be no different.

I had a vintage Luxman amp where the 4 transistors were mounted on the rear side heatsink and connected to the PCB through wires. I was looking for pic but can't seem to find it.

So it would depend on the implementation I guess.

BTW, these look very promising: Buy Corsair CPU Cooler | Corsair CPU Cooler in India

You must be referring to Suds98. I was dabbling of making a F5 but later changed my mind.

A couple of our FMs dissuaded me from buying from the gent.

Hi capt,

I think he is referring to suds not Sud98.

Regards,

Sachin

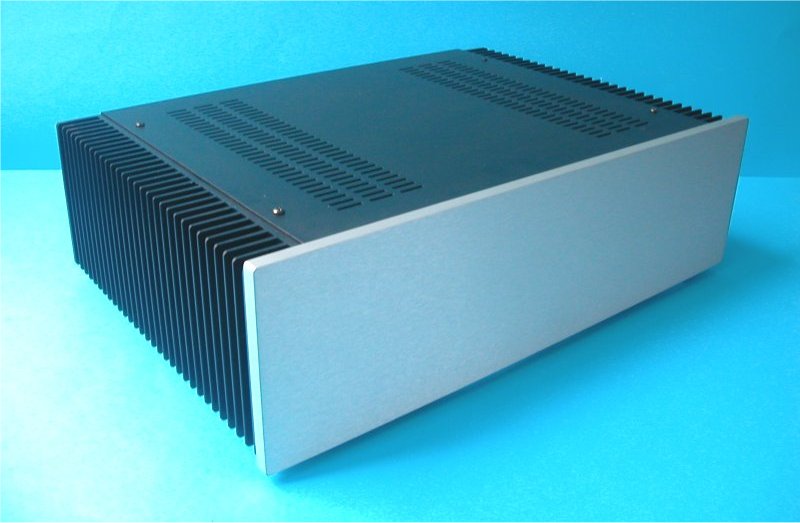

I want to DIY a vertical configuration. Even my toroid is only 4.5 cm high. I want a chassis with inner dimensions of 6 cm wide by 30 cm deep and 30 cm high which i will mount vertically so the heat sinks mounted on the sides are 1 square feet each with the top panel having laser cut vents. Unfortunately I am not finding any heatsinks for the same in chandigarh.

If you can arrange similar heat sinks all that is needed will be an anodised front panel and 3 mm top, rear and bottom panels. The top and bottom ones may be vented ideally.