Anil kumar

Well-Known Member

Hi all, i was looking for an easy solution for some good DIY bookshelf speaker stands which i am building for a friend of mine. Here every part is custom made. Initially everything was worked out on paper for a good looking stands. For the purpose i am using 2.50" dia Aluminium (2 mm thick) pipe and solid rubber wood for top & bottom plates which is much cheaper than teak & oak. Pipe ends are fitted with machined aluminium mount brackets, this holds wood plates with the help of 3 sets of 5 mm stainless steel allen bolts (120 degree apart) & these blocks are threaded to accept 5 mm bolts. Top wood plate sits on the machned bracket, wood plate has 3 counter sink holes for allen bolts. Similarly bottom plates are fitted 3 bolts which holds the heavy 1.3kg MS powdercoated counterweight at the bottom for greater stability. A wire management path keeps speaker cables safely organized (speaker cables runs inside of the tube). Adjustable aluminium spikes are yet to be machined. These speaker stands will be incredibly solid and sturdy. Rubber wood will have beveled corners which will be polished & spray enameled. Aluminum columns & brackets will be powder coated.

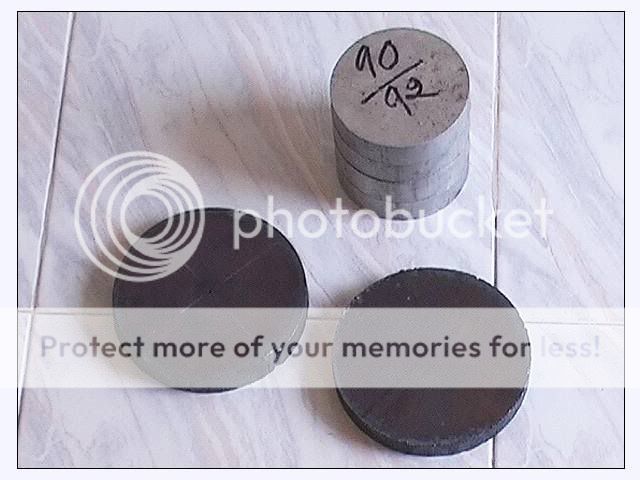

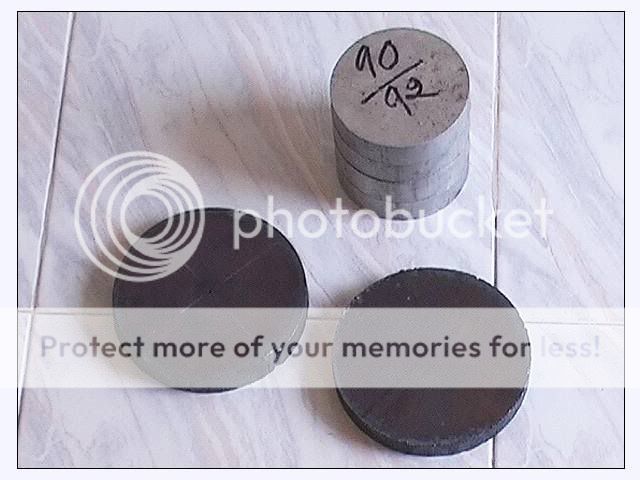

Aluminum & MS blocks ready for machining....

Aluminum & MS blocks ready for machining....

Last edited: