Hi Folks,

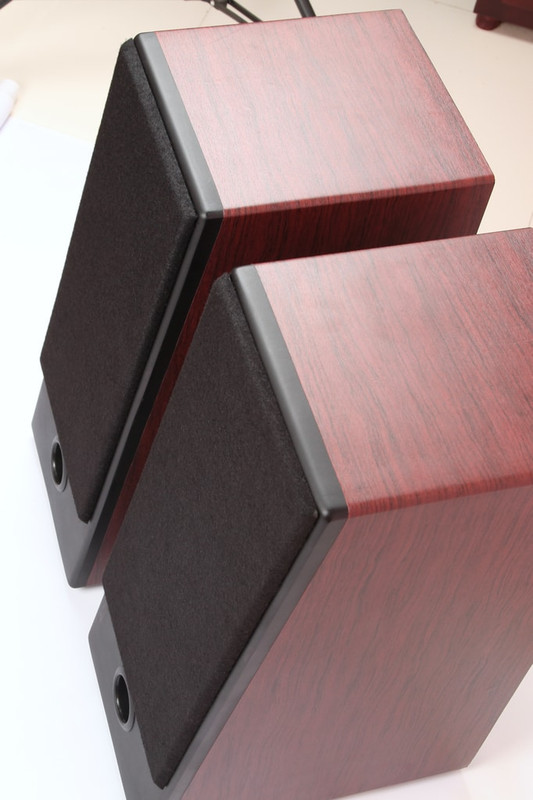

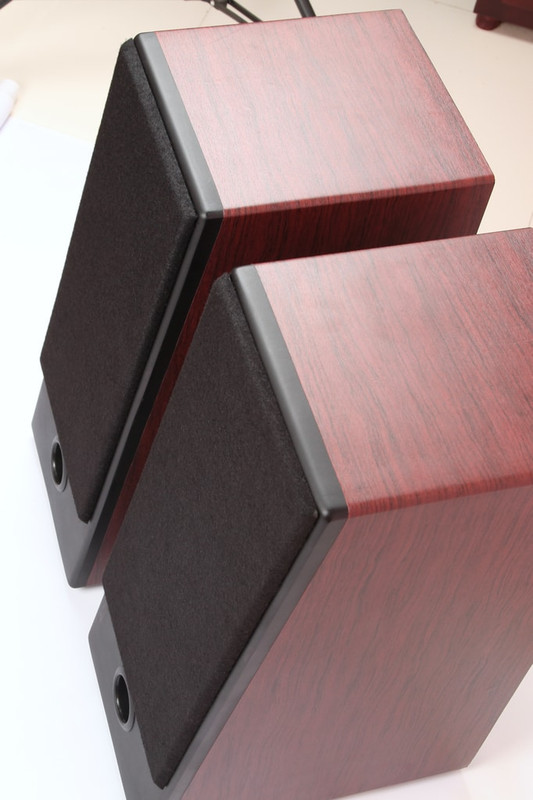

Just finished a bookshelf with Peerless and Vifa drivers for one of my friend according to his taste!

Cabinet volume is (Approx): 38 Liters

Type: Vented

Frequency range: 45Hz - 40KHz

Sensitivity (Approx) : 90 dB/1W/1M

Finish: Wood Laminate

Power: 100 Watts

The drivers I have used are:

Tweeter: Tymphany (Formerly Vifa) XT25SC90-04 Dual Ring Radiator

Woofer: Peerless - 830657-6.5" SDS

The cabinet is braced internally to reduce the resonance and the inside wall is damped with Polyfill.

This can be used as a main speaker for stereo music listening or can be used as front (L/R) speakers in a home theatre setup.

Overall this is sounding very nice and is pretty happy with the results.

I Just thought of sharing few images of the build process below.

Just finished a bookshelf with Peerless and Vifa drivers for one of my friend according to his taste!

Cabinet volume is (Approx): 38 Liters

Type: Vented

Frequency range: 45Hz - 40KHz

Sensitivity (Approx) : 90 dB/1W/1M

Finish: Wood Laminate

Power: 100 Watts

The drivers I have used are:

Tweeter: Tymphany (Formerly Vifa) XT25SC90-04 Dual Ring Radiator

Woofer: Peerless - 830657-6.5" SDS

The cabinet is braced internally to reduce the resonance and the inside wall is damped with Polyfill.

This can be used as a main speaker for stereo music listening or can be used as front (L/R) speakers in a home theatre setup.

Overall this is sounding very nice and is pretty happy with the results.

I Just thought of sharing few images of the build process below.

Last edited: