Subbu68

Well-Known Member

In my intro I had written that I got hooked to this forum through the thread on Ahuja 12FRX. Got a pair of Ahuja 12FRX with the intention of replacing the K-28 woofer of my Klipsch Heresy III with this full ranger, remove the mid and tweeters (horns), blank out the holes or leave the tweeter with a simple capacitor around 1.5 - 2 mfd. HIIIs cost me INR 2lac in UAE in 2016, is a special edition in California Black Walnut and lambswool grill - expensive and too pretty to be cannibalized.

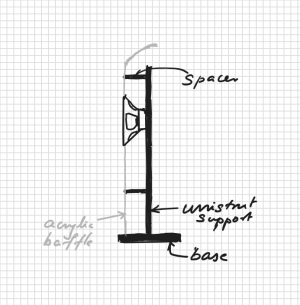

Then seeing the designs (discussions) with Ahuja 12FRX of some of the members here @Sumanta, @Hari Iyer and on the net @Sumanta OB idea has taken over. Made a cardboard baffle nearly 95cm x 95cm (it was 45cm x 45cm earlier) to try out the speaker. Currently they are perched on a stool with center of the speakers at 700mm from floor, angled to point at my ears some 3m away. OB has smitten me.

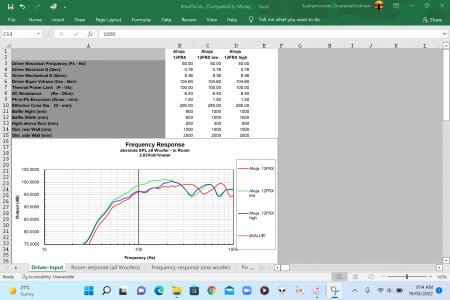

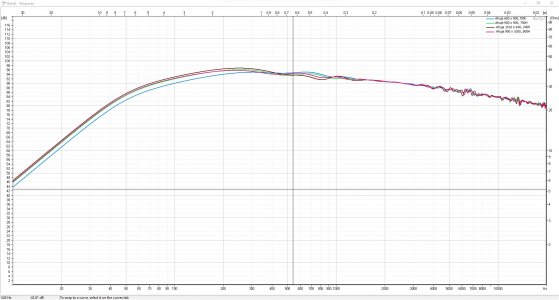

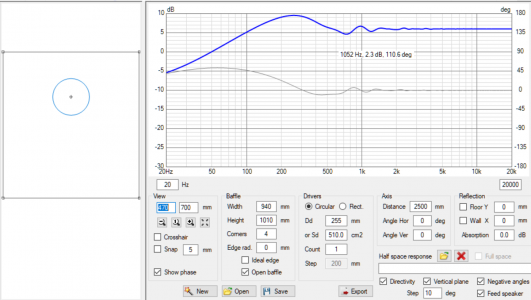

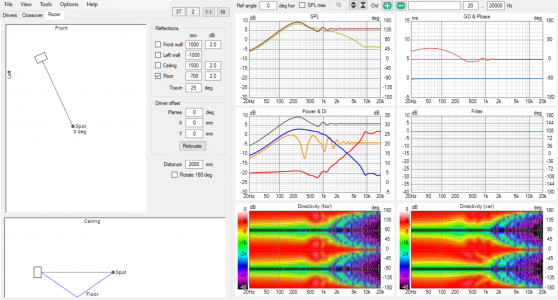

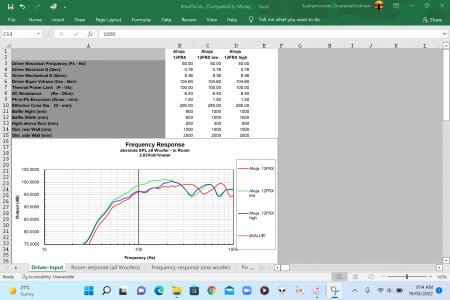

Embarked on some research and stumbled upon a worksheet Xbaffle and playing with it got a few options as below. Results are below. Found that wider the baffle the first dip moves 100Hz.

Any further considerations to be given?

Sorry if I bored you with my rant.

Then seeing the designs (discussions) with Ahuja 12FRX of some of the members here @Sumanta, @Hari Iyer and on the net @Sumanta OB idea has taken over. Made a cardboard baffle nearly 95cm x 95cm (it was 45cm x 45cm earlier) to try out the speaker. Currently they are perched on a stool with center of the speakers at 700mm from floor, angled to point at my ears some 3m away. OB has smitten me.

Embarked on some research and stumbled upon a worksheet Xbaffle and playing with it got a few options as below. Results are below. Found that wider the baffle the first dip moves 100Hz.

Any further considerations to be given?

Sorry if I bored you with my rant.