VinylShakti

Member

Thanks for this information. really needed it. Cheers

Question: Is it really worth the hassles?Yes they have the FB account also.

https://www.facebook.com/basant.lunia?fref=nf

Seems to be reliable source.

How to get it transported to Bangalore, if I going to buy only one sheet of 8x4

Question: Is it really worth the hassles?

How expensive driver are you going to put in the boxes made of so-called high quality 'plywood'?

I'm just curious.

Sent from my Nexus 5 using Tapatalk

Define "ideal", please. And irrespective, what is your point?First of all, all reviews or listening scenarios are not ideal.

Are you referring to the driver being braced/coupled?A driver which moves a lot of air, will definitely perform better with heavy bracing IMHO.

In theory, yes, of course. Is it audible?Let's consider a driver with 10in or more overall diameter and let's consider the driver goes really deep like 30-40hz. If that type of drivers are put in a sealed or ported box, without proper bracing the cabinet will resonate and will generate unwanted frequencies which will not be very pleasing.

Yes.B&W uses patented (and very intelligent) bracing design in matrix, pm series IMHO. Which not only decreases box resonance, but also cancels standing wave.

That's why they cost so much.

I didn't want to put a # because all ears are not created alike. What's normal for me may be abnormal for you. Also the distance from the source matters.By 'normal' spl, what db range do you refer to?.

Tiny = ?Maybe the bracing (or no bracing) is not audible in a/b test with tiny driver or a very low volume (like 50db or so).

You measure driver T/S parameters. Then build the box based on those parameters. Then measure FR & IMP of the drivers in the box. And then you design the crossover based on those measurements. But all this is OT.The first step in building/making a box is to measure accurately the drivers individually if you have a 2 or 3 way,then accordingly design the xover which is a difficult job if done correctly can produce great results,then comes designing the box and tunning the cabinet.

Define "ideal", please. And irrespective, what is your point?

Are you referring to the driver being braced/coupled?

In theory, yes, of course. Is it audible?

I didn't want to put a # because all ears are not created alike. What's normal for me may be abnormal for you. Also the distance from the source matters.

Tiny = ?

3"?

4"?

6"?

8"?

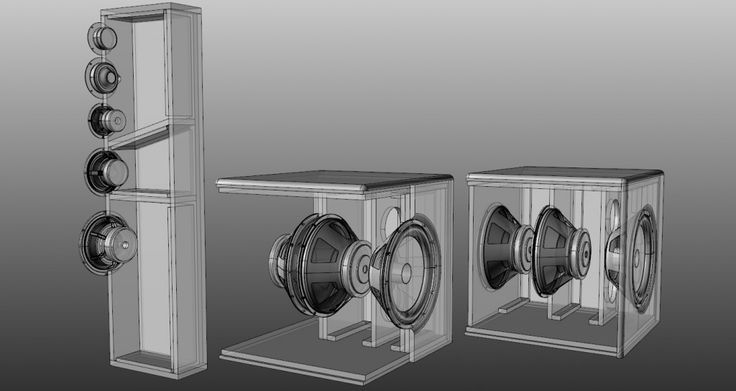

for closed box, the deadness of the box is of paramount importance. For this, bracing is needed, and few speaker designs I see (in India and outside, DIY or commercial) have good bracing. I am 100% certain that a very well braced MDF enclosure (I am thinking B&W's matrix bracing here, which is seriously top-notch) will give you a better sounding final speaker than an inadequately braced speaker made with any other ply or wood.

A driver which moves a lot of air, will definitely perform better with heavy bracing IMHO.

Let's consider a driver with 10in or more overall diameter and let's consider the driver goes really deep like 30-40hz. If that type of drivers are put in a sealed or ported box, without proper bracing the cabinet will resonate and will generate unwanted frequencies which will not be very pleasing.

Maybe the bracing (or no bracing) is not audible in a/b test with tiny driver or a very low volume (like 50db or so).

Use ordinary 20mm commercial ply for the braces (NEVER use MDF).

You measure driver T/S parameters. Then build the box based on those parameters. Then measure FR & IMP of the drivers in the box. And then you design the crossover based on those measurements. But all this is OT.

If anyone can hear the difference between a supposedly well braced cabinet and a supposedly inadequately braced cabinet while listening to music at a "normal" SPL, I'll eat the T.O.I. The Sunday edition with the supplements.

https://www.audioholics.com/loudspeaker-design/detailed-look-proper-loudspeaker-cabinet-bracing

Regardless, increasing the stiffness of a cabinet is always beneficial in reducing the resonant peaks that occur under dynamic load. There really are no circumstances under which a loudspeaker engineer would want to lower the resonant frequency of a cabinet by reducing the number of braces if the goal is to improve fidelity.

Interesting! Is it because of higher propensity for flexing?

what about the bbc thin wall philosphy used by harbeth etc?

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

MIGHT be inaudible, yes.Your comment seems to indicate that you believe that the difference between well-braced and inadequately braced cabinets is inaudible.

The URL was posted NOT to support my assumption that the effect of proper bracing may be inaudible but just as information about why bracing needs to be done well. My apologies to all because I didn't call this out explicitly.The URL you have given seems to say the opposite (with caveats about ensuring that the bracing is effective). See this quote from the article you referred:

Just what I've stated: At "normal" [yes, it's vague and I cannot quantify it with a blanket # so it's fine to nit pick the term] listening volume, when listening to music, I theorize that the effect of bracing might be inaudible.So -- what point are you trying to make? Am genuinely confused.

You've been on the forum long enough for me not to point this out but I'll do it all the same. Bass is not just a function of a driver [and it's size] alone BUT is a function of a driver + the enclosure it is mounted on. I've heard sub-bass frequencies from 3" speakers too WHEN they are mounted in properly designed transmission line or bass reflex boxes so all I can say is that your point of reference which co-relates bass with the size of a driver is incorrect.Maybe. 'Tiny' is again a vague term. For me a 6" driver is very small - if it is considered for bass. Hope I am able to establish my point of reference.