Anil kumar

Well-Known Member

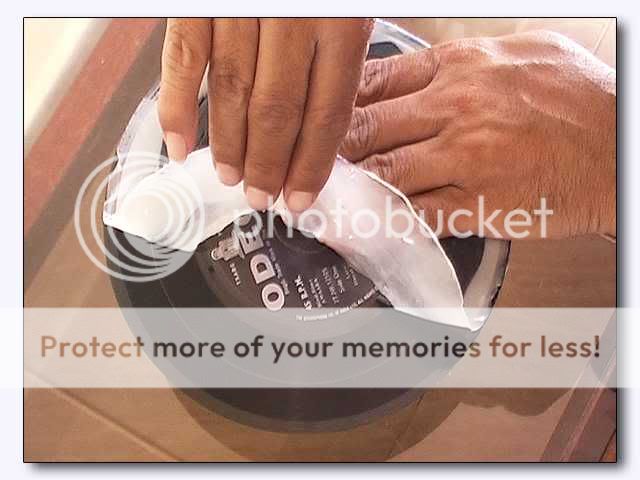

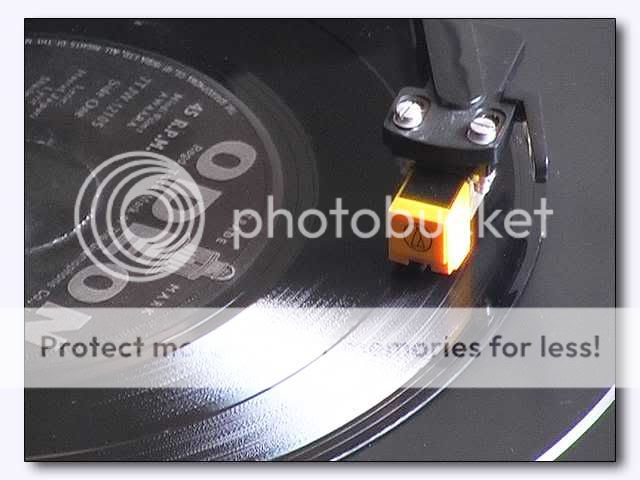

This technique produced a dramatic, near elimination of surface noise.

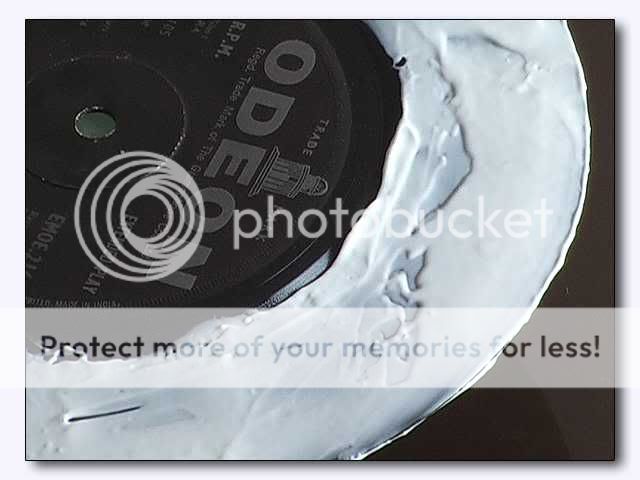

I used FEVICOL SH [polyvinyl acrylate] as a medium to eliminate surface noise.

Plastic vinyl is very resistant to glue adhesion. This wood glue being predominantly made up of polyvinyl acrylate and is a close cousin to polyvinyl chloride [LPs] so they get on well together without any plasticizing transfers. When they do come apart, lots of junk caught in the grooves lifts off with the FEVICOL glue.

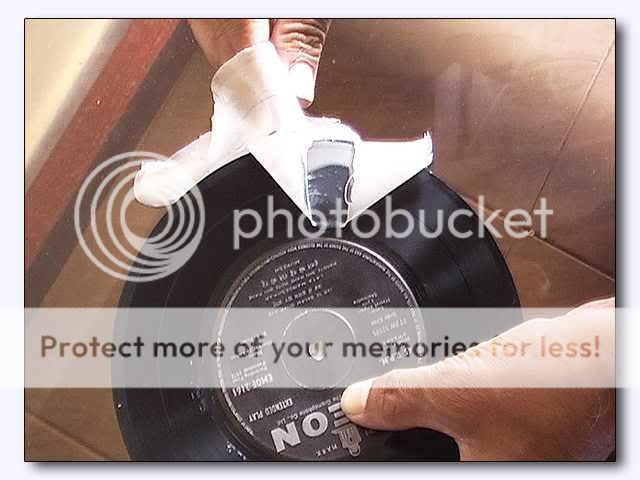

First, record was cleaned with Pril liquid soap with smooth brush.

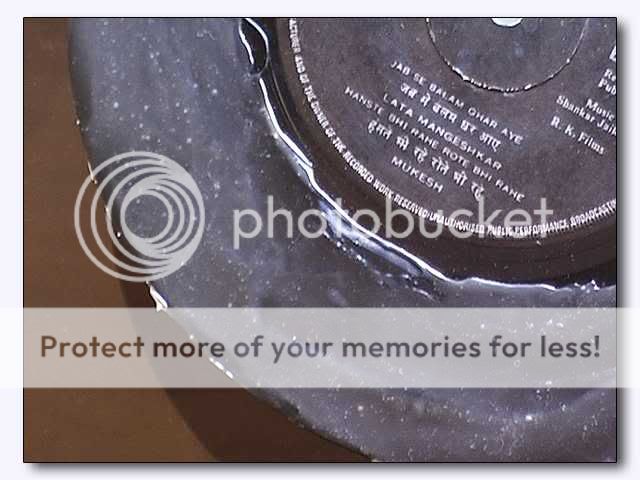

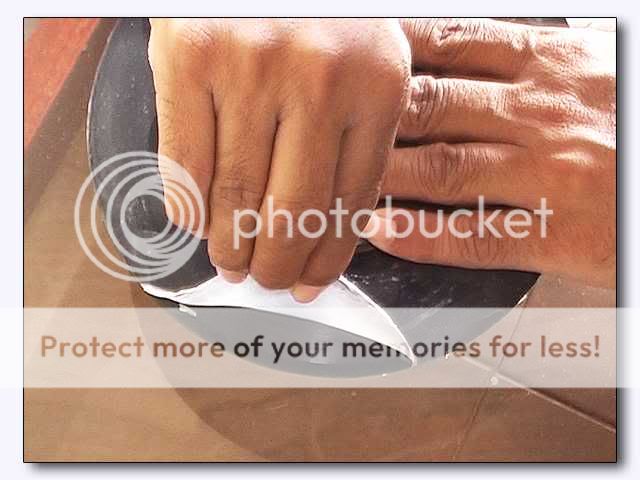

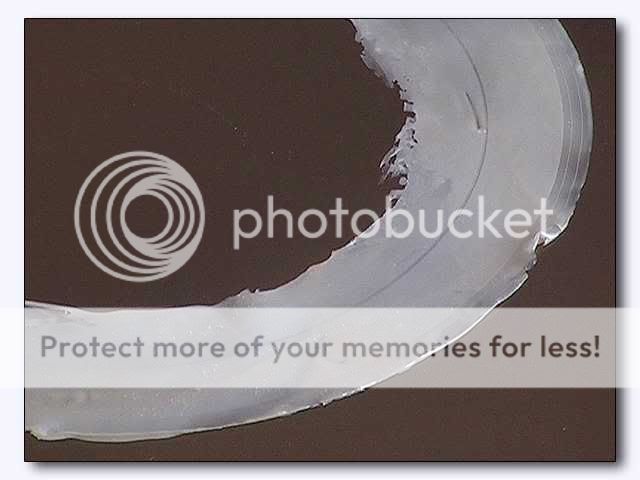

After drying Fevicol was applied, i used an old plastic visiting card to spread the glue on the record. You can also use a old credit card for this job, make sure not to apply Fevicol on the label. Apply little bit thicker toward the lip, so glue lifts off without any problem. Normally this should take about 6-8 hours to dry. After 8 hours of drying dried glue was removed from the edge.

You may require 30 - 40 grams of glue per LP per side.

I used FEVICOL SH [polyvinyl acrylate] as a medium to eliminate surface noise.

Plastic vinyl is very resistant to glue adhesion. This wood glue being predominantly made up of polyvinyl acrylate and is a close cousin to polyvinyl chloride [LPs] so they get on well together without any plasticizing transfers. When they do come apart, lots of junk caught in the grooves lifts off with the FEVICOL glue.

First, record was cleaned with Pril liquid soap with smooth brush.

After drying Fevicol was applied, i used an old plastic visiting card to spread the glue on the record. You can also use a old credit card for this job, make sure not to apply Fevicol on the label. Apply little bit thicker toward the lip, so glue lifts off without any problem. Normally this should take about 6-8 hours to dry. After 8 hours of drying dried glue was removed from the edge.

You may require 30 - 40 grams of glue per LP per side.