What a splendid looking deck, in pristine condition. Congrats!

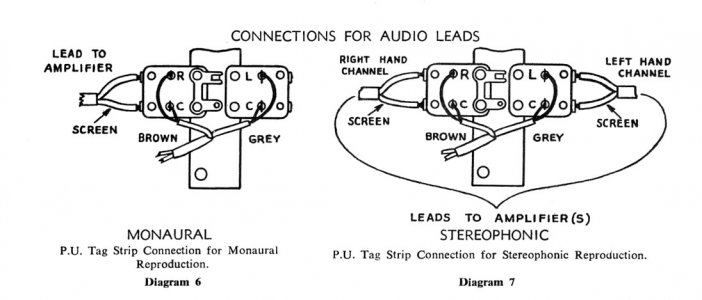

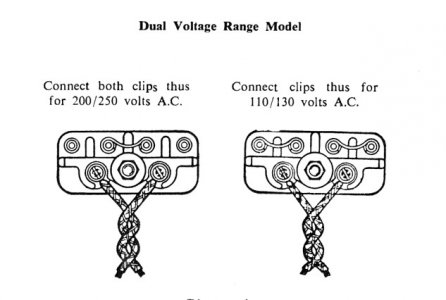

The audio wiriing for Garrards RCs is actually very easy to fix. For the 210, the wiring is for 2-channels even though many used just one pair for mono based on application (Radiograms, table-top record players with inbuilt amps, etc). Here are the wiring diagrams for both the audio and AC leads.

View attachment 72678View attachment 72679

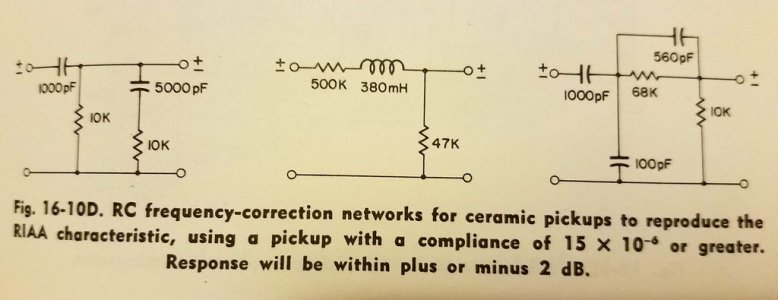

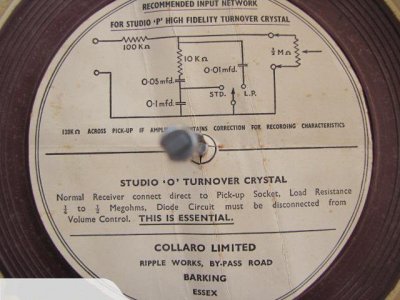

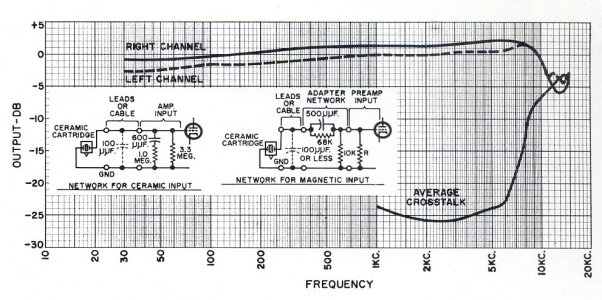

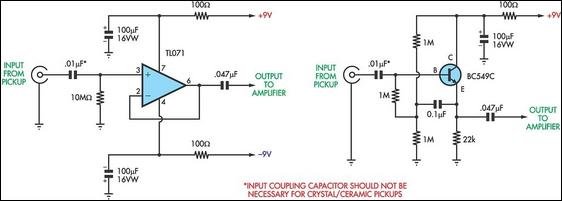

A pic of the mesh would be great for reference but I assume you are referring to the shield of the wire. The shield has to be grounded. Noticed you are using a ceramic phonocartridge on the Garrard. Do you have a ceramic phonostage or an amplifier with a ceramic/crystal input to use with this changer? When I had mine, I put together a small phono stage and wired it directly to this connector. Also ensure that you have a groud lead from the Garrard chassis running to your amplifier. This will give you a zero-noise listening experience.

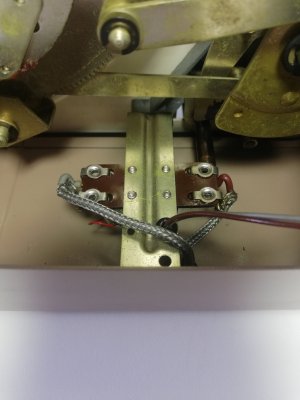

Lastly, one aspect to also check is the AC switch (the on/off deck switch which is enclosed under the plastic cap). This will never fail but since you are servicing it, it would be good to give it a clean up. This model of changer does not have a spark suppressor capacitor and you are likely to hear a 'thump' sound through the speakers every time your changer switches on and off. Connecting a spark supressor capacitor across this deck switch will ensure that the thump goes away and also the switch is saved from sparks and arching. Garrard-type spark supressors for models like the 301, 401 and 4HF are easily available online but if you are looking for a less-expensive option, a 0.05uf, 1000 volt ceramic capacitor (or any other type of non-polar capacitor) can be used for spark suppression. Kindly note that non-polar capacitors like ceramics, can be used in both AC and DC applications. Here is a pic of this deck switch:

View attachment 72680