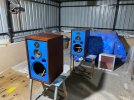

Admirable , thoughtful work !! Bravo !! Very well done.

One thought :

An almost

free possible optimization

experiment Sadik :

What would happen, sonically, if all the

entire distance of the speaker leads, amp to crossover and crossover to drivers, had their polarities not touching each other? Just pull apart the two molded polarities where they are co-joined during manufacture, and distance the positive and negative speaker lead wires? " No touch " each other, ............. at all.

I usually hear it as an " openess " in the highs, a better sense of the venue's recorded space, and in slightly cleaner and better dynamics. If my

amp to driver voice coil leads touch each other in ONE location, I usually , almost subconsciously, can tell there is a system

degrade of playback. A loss of air and system presence.

Perhaps, ( I do not

know,

TRY it and tell us all ) the

same may apply on your less sensitive speakers !!

We would all learn something . Mine are 103 dB , two-way horn loaded, so it is telling of such.

Again,

nice job !!

Jeff

One other implementation detail :

The speaker wires, resting on the rug, are a degrade. Energy is being lost in transmission !! Raise them off the rug, suspended in free air with non-plastic materials. Why not a series of chop-stick tripods held together by a natural cotton thread ? J

ust listen to that, before and after.

Better sounding ?? Better music energy-delivery to the drivers ???

Read on-line Mapleshade Audio, "Wire Management", written by Mr. Pierre Sprey. He is correct - in my listening experiences. Have fun.