elangoas

Well-Known Member

Am now considering few options.. Thinking to use the entire width of front wall (14 ft) from left to right where it meets the ceiling, due to the pre-cut sizes aval.. 1000mm (1 meter) x 500mm (0.5 meter) x 100mm (thickness)..

Option 1 : If i cut the standard size in to two equal halves, then it becomes 500mm (L) x 500mm (W) x 100mm (D) (thickness), alsmot a square dimension.. I can then stack each of these pieces next to each other for the entire 14ft wall..( where it meets the ceiling) effectively making the trap 20 inch x 20 inch square trap, which will have two surfaces open to the room..

Option 2 : If i just choose to use the dimensions as it is 1000mm (1 meter) x 500mm (0.5 meter) x 100mm (thickness).., i would choose to use 500mm as width.. I can stack 5 pieces on to top on one another.. This also makes it 500 mm x 500mm, without the need to cut.. (think this is easier)..

Option 1 & 2 makes it super chunk traps as the thickness is approx 20 inches, effectively making it absorb freq (1/4th wave length) & to reduce decay times too.. (thicker absorption)..

Option 3 : to hang each panels with frame starting near the ceiling across the front, side & back walls.. This makes more absorption area and reduced thickness..

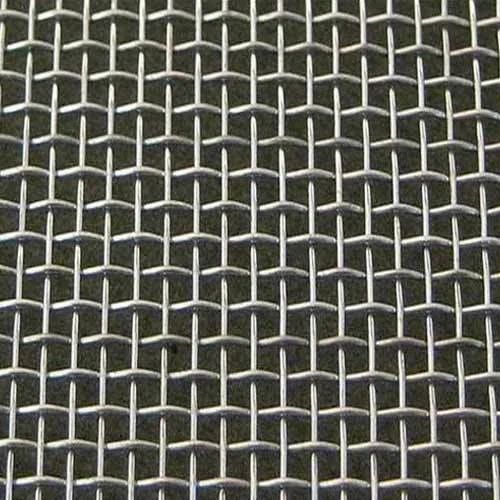

Option 4 : To make 18 inch wooden frame with L bracket support from each wall.. spread close knitted metal mesh, fill with thin layer of polyfill as base layer and stuff as much as loose wool inside it.. (More like a kind of basket to hold the wool)..At this point there is no clarity on the density of loose wool, am guessing it should be <48kg/m3, and should cost less.. After filling, i can cover the whole thing with spandex (Acoustically transparent) cloth (or) Gada cloth, even cheaper cloth fairly translucent (known locally here in TN or damask cloth from bombay dyeing).. Should absorb only the lows..

With all the above options, i have thought to keep the absorption away from speakers path, to absorb only low freq as much as possible in the room..

Which of the above is good (or) if you have any other options.. Please let me know..

Option 1 : If i cut the standard size in to two equal halves, then it becomes 500mm (L) x 500mm (W) x 100mm (D) (thickness), alsmot a square dimension.. I can then stack each of these pieces next to each other for the entire 14ft wall..( where it meets the ceiling) effectively making the trap 20 inch x 20 inch square trap, which will have two surfaces open to the room..

Option 2 : If i just choose to use the dimensions as it is 1000mm (1 meter) x 500mm (0.5 meter) x 100mm (thickness).., i would choose to use 500mm as width.. I can stack 5 pieces on to top on one another.. This also makes it 500 mm x 500mm, without the need to cut.. (think this is easier)..

Option 1 & 2 makes it super chunk traps as the thickness is approx 20 inches, effectively making it absorb freq (1/4th wave length) & to reduce decay times too.. (thicker absorption)..

Option 3 : to hang each panels with frame starting near the ceiling across the front, side & back walls.. This makes more absorption area and reduced thickness..

Option 4 : To make 18 inch wooden frame with L bracket support from each wall.. spread close knitted metal mesh, fill with thin layer of polyfill as base layer and stuff as much as loose wool inside it.. (More like a kind of basket to hold the wool)..At this point there is no clarity on the density of loose wool, am guessing it should be <48kg/m3, and should cost less.. After filling, i can cover the whole thing with spandex (Acoustically transparent) cloth (or) Gada cloth, even cheaper cloth fairly translucent (known locally here in TN or damask cloth from bombay dyeing).. Should absorb only the lows..

With all the above options, i have thought to keep the absorption away from speakers path, to absorb only low freq as much as possible in the room..

Which of the above is good (or) if you have any other options.. Please let me know..

Last edited: