Hi Friends, Now a days I am not very active on hifivision, In fact I am not getting enough time to document my built journey so I thought of at least make a thread where I can share the photos of the complete enclosures. So from now on I will be posting photos of all my enclosure projects in this thread.

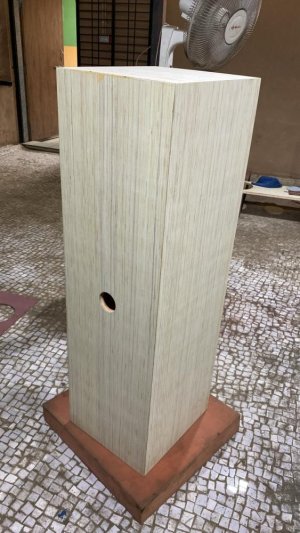

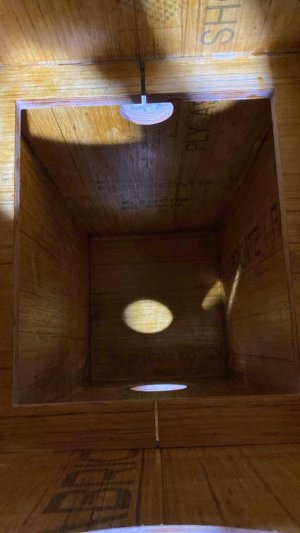

So the First post in this thread are custom designed enclosures, they are huge with external dimensions as 1280 (H) x 380 (W) x 420 (D)

These enclosures are RAW finish. (No Veneer, No Putty work, no Primer no Sealer no clear just RAW enclosures and Shellac Polish). One of my hardest project till date because I had to take great precautions during cutting and assembling them. The DIY guys may be very well aware of cutting plywood in the opposite grains, The Plywood gets chip off while cutting along opposite grains of wood. A slight chip off will ruin the complete look of enclosures.

Lets enjoy some final built photos of enclosures

While taking up this project i had discussed with user and made it clear about all the difficulties which may occur in the enclosures, (like chipping of plywood while cutting in opposite grains of wood, some air pockets in the internal of plywood after cutting, or may it be some dents on surface of plywood etc) he also understood the same and gave me green signal to go ahead and make the project happen. Secondly making grill is not my cup of tea but still i manage to make a good looking grill and for such a huge enclosure the grill was also another task.

But in the End this Project turn out to be a Master Piece. Next Project is soon on the way... Stay tuned.

So the First post in this thread are custom designed enclosures, they are huge with external dimensions as 1280 (H) x 380 (W) x 420 (D)

These enclosures are RAW finish. (No Veneer, No Putty work, no Primer no Sealer no clear just RAW enclosures and Shellac Polish). One of my hardest project till date because I had to take great precautions during cutting and assembling them. The DIY guys may be very well aware of cutting plywood in the opposite grains, The Plywood gets chip off while cutting along opposite grains of wood. A slight chip off will ruin the complete look of enclosures.

Lets enjoy some final built photos of enclosures

While taking up this project i had discussed with user and made it clear about all the difficulties which may occur in the enclosures, (like chipping of plywood while cutting in opposite grains of wood, some air pockets in the internal of plywood after cutting, or may it be some dents on surface of plywood etc) he also understood the same and gave me green signal to go ahead and make the project happen. Secondly making grill is not my cup of tea but still i manage to make a good looking grill and for such a huge enclosure the grill was also another task.

But in the End this Project turn out to be a Master Piece. Next Project is soon on the way... Stay tuned.