Installment next:

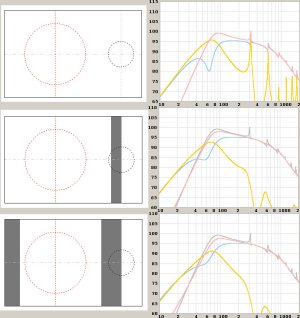

The words lining/damping/stuffing/filling are applied interchangeably on the boards sometimes but the goals/effects are different even if they're part of the same activities. For reflex boxes, ignore stuffing and ignore filling as it commonly means polyester (Dacron) pillow stuffing used to fill pipes/TL's, etc. Sometimes it is done, anyway, but the effects are small/subtle and basically inapplicable to big old Altec cabs until it gets quite dense. Damping, technically, is the "systems" bit where, engineers try to match resonant bandwidths and quality factors of a driver and a volume+port to each other for whatever their goals are, often to make the net load appear more resistive than reactive to the amp. The thing is, the word is applied to voicing and interchanged with lining and so on--because the same activities address both, so people can get confused easily.

The semantics are a nebulous mess but it's the end-result on sound that one cares about. That's voicing, too. That's spectral content. Tuning might be the same, damping might be the very close, but what we hear (and can see in spectra) or measure in impulses is different. This veers into subjectivist / objectivist territory fast but here's a way to proceed and see for yourself. You will have to think about this quite a bit in advance, but, once planned, it'll be maybe 20 minutes of work. Think about how to "stage" the resistive/absorbent materials where you want them and plan that out.

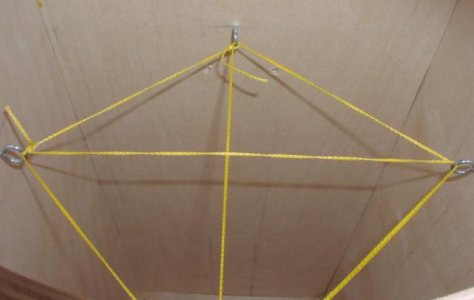

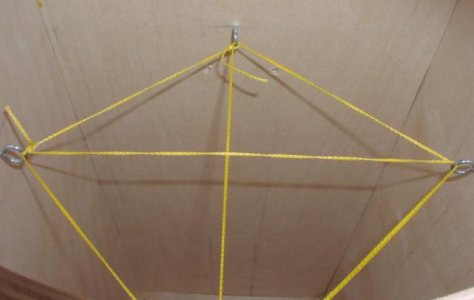

Make 3 snippets of sample tracks--one with heavy percussion, one with large soundbodies (cello or piano, say), and one with a voice of someone you know Well--like a spouse or family member. Get a bunch of lining material ready and some duct tape to hold it temporarily. You can use eyelets and string or netting or...let your own mind/creativity work with what you have available.

A reflex box with removable front is perfect, if that's the case, BTW, for what I do. Ensure that the connections to the driver/xo/amp etc are tight and CANNOT come loose because you'll do this "live" while moving things (and those drivers are Heavy). Lay the cabinet on its back on the floor and get ready to iterate and replace the front, just allowing gravity to hold it down. You don't have to have the completely air-tight seal for this activity--it helps, but it's a pain, too. I use rope caulk sometimes (pain to remove after squashed-into grain) or (dried) bead of RTV silicone if prototyping (also pain to remove) as a gasket. The kinds of changes you're making here don't depend on that gasket sealing -- this is macro/rough & large changes rapidly while running live. If you think you might like something and want to seal it quickly, you can use packing tape (mylar) but it doesn't impact the big changes.

If you've never done the experiments before--yes--start empty. Compare the 3 tracks...3 or 5 seconds of each. Make a change, repeat. Which makes the drums sound best? Which makes the big soundbody sound best? Follow your ears. Your job is to find the best compromise for the combination of the 3 types of material.

If you get something close to acceptable, close it up, shut it off, and come-back another day with fresh ears. I've done that, off-and-on, for weeks and months on different boxes, only to have to remove things and add a brace or something to fix a different cabinet problem or a reflection.

Even if you can't measure, you can use a tone generator app to get a sweep and listen for anomalies as a separate approach.

There's more to say about related activities, but this is probably enough out of me for now. So far, so good? I sincerely applaud the interest in the inquiry and, as you can tell, I think it might be kind of important

The time you spend on this will serve you for life, I promise you that.

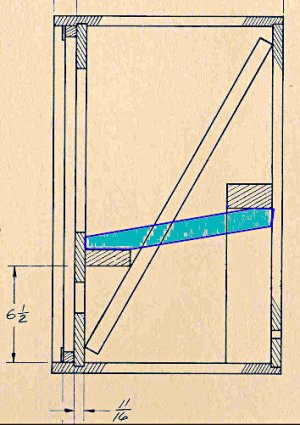

Oh--if you have the rockwool, try one big-old diagonal bottom to top and front to back, whole cabinet width. You're mucking with standing waves in there and there's not only the 3 directions, but there are tangential ones bouncing around (think 5 walls etc) cross-corner and all that. It's a circus in there--and it all comes out through the cone and port and is transmitted through cabinet walls (and entirely separate but also important topic).

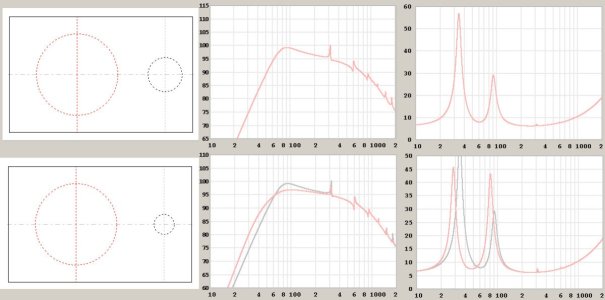

Parenthetically, not having 601C data and knowing 414's are closer than 604's to them, what I'm seeing is already damped decently in the 614, it just doesn't go as low as you might want (say in a bigger thing like a 612). If you are elevating it to get tweeters to ear-height anyway, perhaps some "wings" (below) as extra "baffle" is worth a try. Certainly corner placment will help if thats available, or at least wall+floor if you can tilt them backwards so the fire-upward. FWIW.

If you have a phone generator, you can find box tuning by holding your finger lightly on the cone where you sweep it. If my hacked-up 414 data (with 601 resonance) is close, it looks like about 64Hz with an empty cab. Where the cone moves the least is the box tuning freq.