You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Batery powered DIY CNC phono stage

- Thread starter sachu888

- Start date

I think its time to work on new PS now,

May be a nice shunt regulated PS?

Great work, skrodahl!!!

Do you plan to make the PCBs available for a GB?

How does the sound differ/improve over the stock CNC, btw?

I would personally love to have the ability to use loading cap on the PCB itself instead of moving it to the cable or TT.

Do you plan to make the PCBs available for a GB?

How does the sound differ/improve over the stock CNC, btw?

I would personally love to have the ability to use loading cap on the PCB itself instead of moving it to the cable or TT.

skrodahl

New Member

Great work, skrodahl!!!

Do you plan to make the PCBs available for a GB?

How does the sound differ/improve over the stock CNC, btw?

I would personally love to have the ability to use loading cap on the PCB itself instead of moving it to the cable or TT.

Thanks for the kind words jls001,

I live in Sweden, so I don't think a group buy is feasible. If, for nothing else, just the cost of shipping alone.

I didn't expect this version to be better than the previous one, simply because the first one was so great. It turns out there is more of everything. More bass, more punch, more mids and highs, more details/3D, more control, richer sound and more "air". There's not too much of anything, it's just more right in my opinion.

This is entirely my opinion though, there is one less resistor in the audio path to "color" the sound. The RIAA filter is redesigned, so that will affect the frequency response to some 0.1dB maximum. Apart from that, the audio path is significantly shorter, and there's a full ground plane. All things combined, that could explain the improvement. The board is much smaller either way, which makes it more practical.

I mounted a couple of LME79720 opamps in the circuit, and I was not at all happy with it. Back to OPA2134, and everything was proper again.

skrodahl

New Member

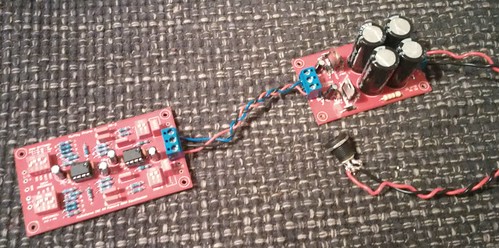

I have been constructing an LM317/337 power supply for the CNC, and it's time to put it to the test. I can say straight away that the tests went really well.

The PSU uses a voltage doubler to bring up each half of the rectified signal to above 15V, and then LM317/337 to regulate the voltage. To avoid having to play around with mains power and electrocuting myself, this is powered by a 15V single AC wall-wart.

I chose a wall-wart with a transformer in it, hooked it up and measured the ripple with my multimeter set to Volts AC. It said somewhere between 2-4 mV.

Then I measured the ripple at the power pins on the opamps, to see the effect of the bypass caps on the CNC board. To my surprise, it dropped down to 0.000 mV. That's as low as my meter will go.

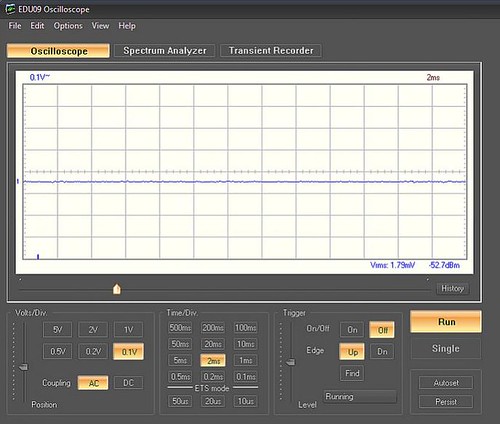

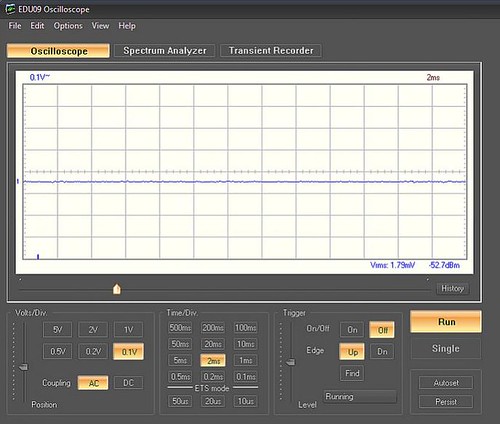

Inspired by this, I hooked it up to the scope and found that the PSU has less than 2 mV ripple before the opamp bypass capacitors:

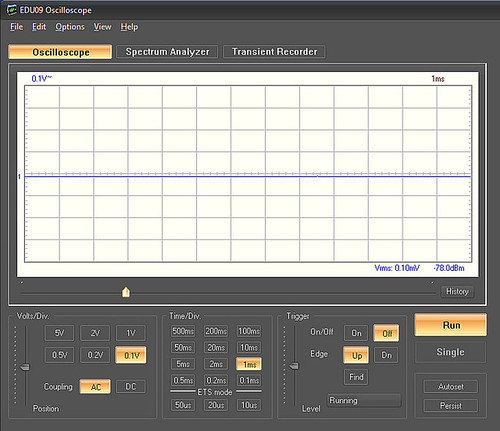

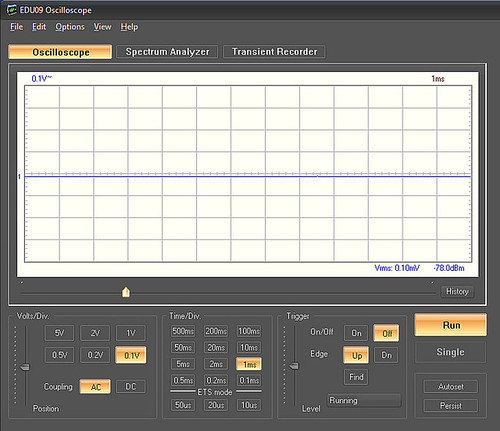

What about after the bypass capacitors? This is what I get on the opamp power pins:

0.1 mV! To be fair, it varies from 0.07-0.14 mV. Still, that's a result to be happy with.

The PSU uses a voltage doubler to bring up each half of the rectified signal to above 15V, and then LM317/337 to regulate the voltage. To avoid having to play around with mains power and electrocuting myself, this is powered by a 15V single AC wall-wart.

I chose a wall-wart with a transformer in it, hooked it up and measured the ripple with my multimeter set to Volts AC. It said somewhere between 2-4 mV.

Then I measured the ripple at the power pins on the opamps, to see the effect of the bypass caps on the CNC board. To my surprise, it dropped down to 0.000 mV. That's as low as my meter will go.

Inspired by this, I hooked it up to the scope and found that the PSU has less than 2 mV ripple before the opamp bypass capacitors:

What about after the bypass capacitors? This is what I get on the opamp power pins:

0.1 mV! To be fair, it varies from 0.07-0.14 mV. Still, that's a result to be happy with.

sachu888

Well-Known Member

There is a similar one designed by Hypnotoad My Low Noise PSU - AudioKarma.org Home Audio Stereo Discussion Forums

Regards

Sachin

Regards

Sachin

Last edited:

skrodahl

New Member

sachu888

Well-Known Member

I have posted few pics here http://www.hifivision.com/diy/53964-dcb1-build-21.html#post651901

Regards

Sachin

Regards

Sachin

saheb11123

Active Member

Can anyone update on the price of the cnc phono? Kit and only pcb?

Nitin Arora

Member

Hi,

I had built this kit with sachin's help for a friend with extremely good results. Sachin was very responsive and helpful so kudos to him for that.

I have a quick question regarding the power supply to the phono. Would it be possible to power this from 2 separate 9v regulated power adapters basically wired the same way as the batteries? My friend is a little keen on getting the batteries out of the equation and I am not particularly in a position to devote time to building a dedicated power supply.

Would really appreciate any inputs on this.

Thanks

Nitin

I had built this kit with sachin's help for a friend with extremely good results. Sachin was very responsive and helpful so kudos to him for that.

I have a quick question regarding the power supply to the phono. Would it be possible to power this from 2 separate 9v regulated power adapters basically wired the same way as the batteries? My friend is a little keen on getting the batteries out of the equation and I am not particularly in a position to devote time to building a dedicated power supply.

Would really appreciate any inputs on this.

Thanks

Nitin

Treat the + and - terminals of two adapters just like the terminals of the two batteries. Make two female sockets on the rear panel to fit the connectors of the adaptors, wire appropriately internally, and you're done. I would recommend 12 volt adapter instead of 9V. I used two adaptors for powering CNC (when I had it for some time). Right now I use the same scheme for powering the Hypnotoad LOMC phono pre. It works well. Try to find linear power adaptor, not SMPS based adapters.

Nitin Arora

Member

Thank you sir. I have a variable voltage one so i can ramp up to +-12v. Thanks

Nitin Arora

Member

Sorry for the confusin statement. omishra sir, I have two separate wall warts that are both adjustables. So i intend to use 2 adapters connected in the same manner as the 2 batteries. Please let me know if this is not ok.

Thanks

Nitin

Thanks

Nitin

greenhorn

Well-Known Member

are there any locally available options/chips that can generate a -ve rail without inductors with enough current for the CNC phono?

Nitin Arora

Member

are there any locally available options/chips that can generate a -ve rail without inductors with enough current for the CNC phono?

Absolutely no idea greenhorn. That is why i want to keep it very simple by using two power supplies.

Thanks

Nitin

reubensm

Well-Known Member

Here are some approaches I've used for single to dual rail conversion:

1) for this approach, you'd need an 18 volt PSU from which you can obtain 9-0-9

2) here's a trick for obtaining 9-0-9 from a single rail tranny

1) for this approach, you'd need an 18 volt PSU from which you can obtain 9-0-9

2) here's a trick for obtaining 9-0-9 from a single rail tranny

Re: Battery powered DIY CNC phono stage

Reuben, these are working with situations and may not work for phono. Let us see case by case.

1) This is voltage divider with 100K resistances and virtual ground at 4.5V. Though its marked as GND it is actual 4.5V. Connecting it to external circuit is not that straight forward. Also it would not deliver current to ground. In case you use 10K resistances and 10000uF capacitors, still it would be okay okay but not excellent.

For this i tried virtual ground with some chip or OPAMP which could allow at least 50mA current.

I faced this issue while OPAMP in to car preamp buffer. So I created virtual ground using TL072. I have updated this into some team-bhp DIY thread.

2) This half wave rectifier and ripple will be always there unless suitable regulation.

So for phono i feel both schemes are won't be advisable.

Reuben, these are working with situations and may not work for phono. Let us see case by case.

1) This is voltage divider with 100K resistances and virtual ground at 4.5V. Though its marked as GND it is actual 4.5V. Connecting it to external circuit is not that straight forward. Also it would not deliver current to ground. In case you use 10K resistances and 10000uF capacitors, still it would be okay okay but not excellent.

For this i tried virtual ground with some chip or OPAMP which could allow at least 50mA current.

I faced this issue while OPAMP in to car preamp buffer. So I created virtual ground using TL072. I have updated this into some team-bhp DIY thread.

2) This half wave rectifier and ripple will be always there unless suitable regulation.

So for phono i feel both schemes are won't be advisable.

reubensm

Well-Known Member

Re: Battery powered DIY CNC phono stage

Great points, it works. In the first instance, brother is using a CNC (sachu version) with a 24 volts single rail polycom phone regulated powersupply wired with the same logic. In the second instance, I have tried it with regulation only using 7815 and 7915 regulators, using a 12 volts, 500 ma tranny. The output was 15-0-15.

Reuben, these are working with situations and may not work for phono. Let us see case by case.

1) This is voltage divider with 100K resistances and virtual ground at 4.5V. Though its marked as GND it is actual 4.5V. Connecting it to external circuit is not that straight forward. Also it would not deliver current to ground. In case you use 10K resistances and 10000uF capacitors, still it would be okay okay but not excellent.

For this i tried virtual ground with some chip or OPAMP which could allow at least 50mA current.

I faced this issue while OPAMP in to car preamp buffer. So I created virtual ground using TL072. I have updated this into some team-bhp DIY thread.

2) This half wave rectifier and ripple will be always there unless suitable regulation.

So for phono i feel both schemes are won't be advisable.

Great points, it works. In the first instance, brother is using a CNC (sachu version) with a 24 volts single rail polycom phone regulated powersupply wired with the same logic. In the second instance, I have tried it with regulation only using 7815 and 7915 regulators, using a 12 volts, 500 ma tranny. The output was 15-0-15.

Join WhatsApp Channel to get HiFiMART.com Offers & Deals delivered to your smartphone!