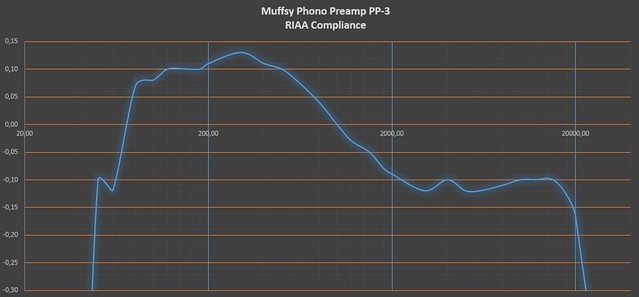

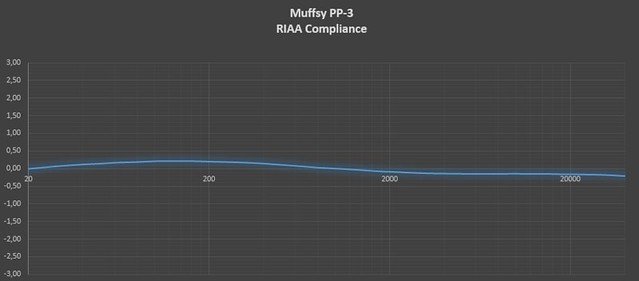

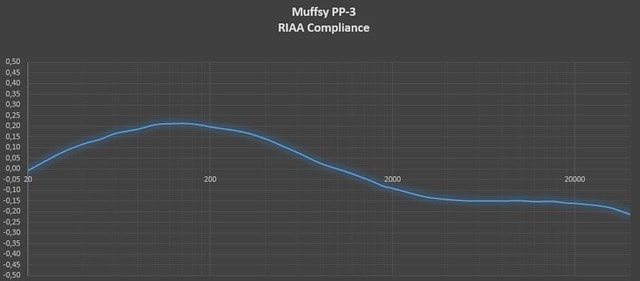

There is only one small 0.11 dB hump at 2 kHz. Except for that, the phono stage actually measures within the stated specifications of +/- 0.025 dB.

Those are phenomenal numbers, skrodahl! Thanks for sharing them.

There is only one small 0.11 dB hump at 2 kHz. Except for that, the phono stage actually measures within the stated specifications of +/- 0.025 dB.

hi Skrodahl,

while i understand that this may be highly op amp dependent, do you have any numbers on the PSRR/ hum for the specific device you tested?

Those are phenomenal numbers, skrodahl! Thanks for sharing them.

You need those resistance to avoid pop n clicks while using switch. It keeps other side reference to ground .

That 100K do required. If you are scared then it could be raised to 220K without any issue. Anyway output impedance will be <100R.Dear Omisha,

I do not have 100k shunt resistors on the Muffsy PP-3 board.

Do I just need to shunt the RCA live to ground?

How does this effect the 100k input impedance of the upstream Jolida Fusion 3502 integrated?

Thanks,

Bela

Dear Omisha,

I do not have 100k shunt resistors on the Muffsy PP-3 board.

Do I just need to shunt the RCA live to ground?

How does this effect the 100k input impedance of the upstream Jolida Fusion 3502 integrated?

Thanks,

Bela

I have 0,47uF teflon DC blocking output capacitors since my amp has a 100k input impedance.

If I include the 100k shunt resistors will those effectively half the input impedance of the amp? If so would I need to increase the DC blocking output capacitors to have the same very good bass response?

I have no shunt resistors now and the FT-3 teflon capacitors are connected the the RCA sockets. I can't see/hear any problem just a beautiful, mind-blowing sound.

If those resistors are indeed needed why aren't they on the PCB?

Regards,

Bela

Hello friends,

I have been using CNC phono since 2015 with Technics 1200 MKII and Shure M 97Xe/M44-7/M92E. The resistance load set is 47K ohms. It was a great gesture from Om, Sachin and Raghu for this CNC existence on my audio chain. I am pretty happy. I also use NAD PP2 on my second system.

Now I am getting on hold a Shure V15 type III with super track stylus. I may change the stylus to VN35HE from JICO in near future.

I am assuming 47K resistance load would suffice but what about the capacitance load. The recommended cap load is 400 to 500 pf. What I recall from any previous conversation that the cap load set in CNC is 200 to 300 pf. Please correct me if I'm wrong.

Do I need to do any tweak for CNC? Please help as I hold very rudimentary knowledge on electronics.

Thanks in advance,

Sourav

Bumped up my question once again. Please revert

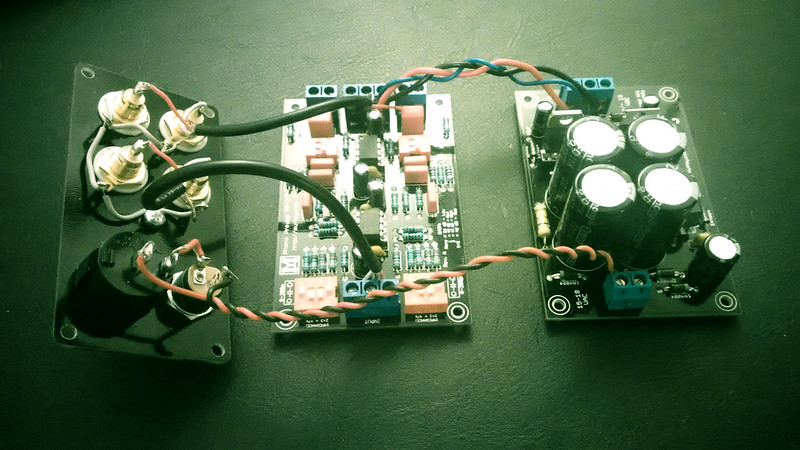

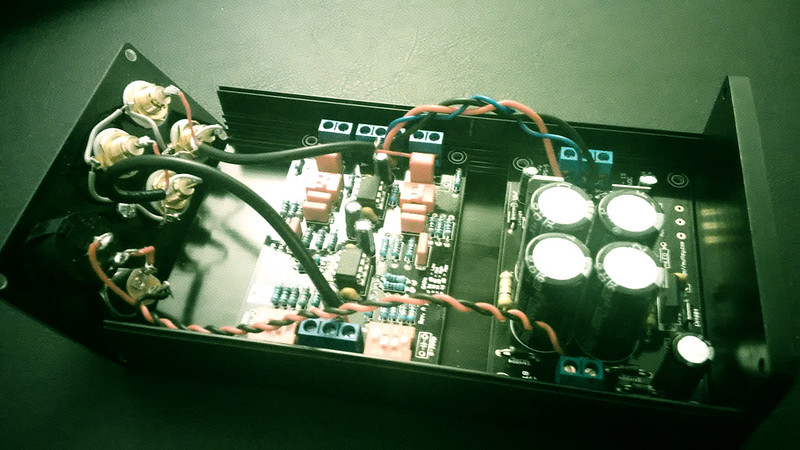

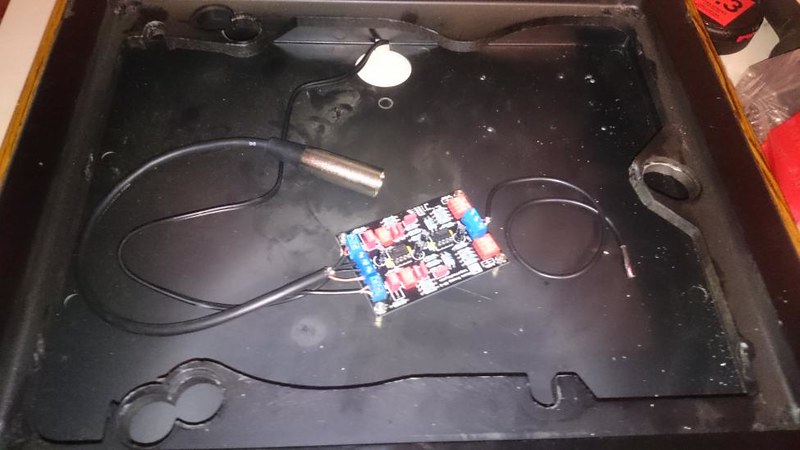

image hosting 5mb[/URL]

image hosting 5mb[/URL]