Kindly go through post #168 here:

http://www.hifivision.com/diy/59385-kuartlotron-error-correcting-super-buffer-17.html to get general idea on how to wire up line level buffer/preamp/phono preamp.

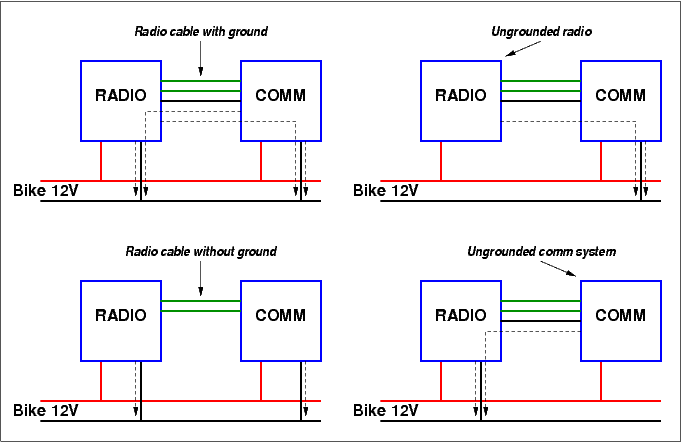

As Sachin mentioned, the first thing not to mix up is the return leads of the RCA input and output sockets WITH the chassis. Cabinet-mounted RCA sockets come with two plastic washers which are meant to insulate the barrel of the RCA socket as it passes through the hole in the cabinet. This ensures that the signal ground/return and the chassis are NOT at the same electrical potential.

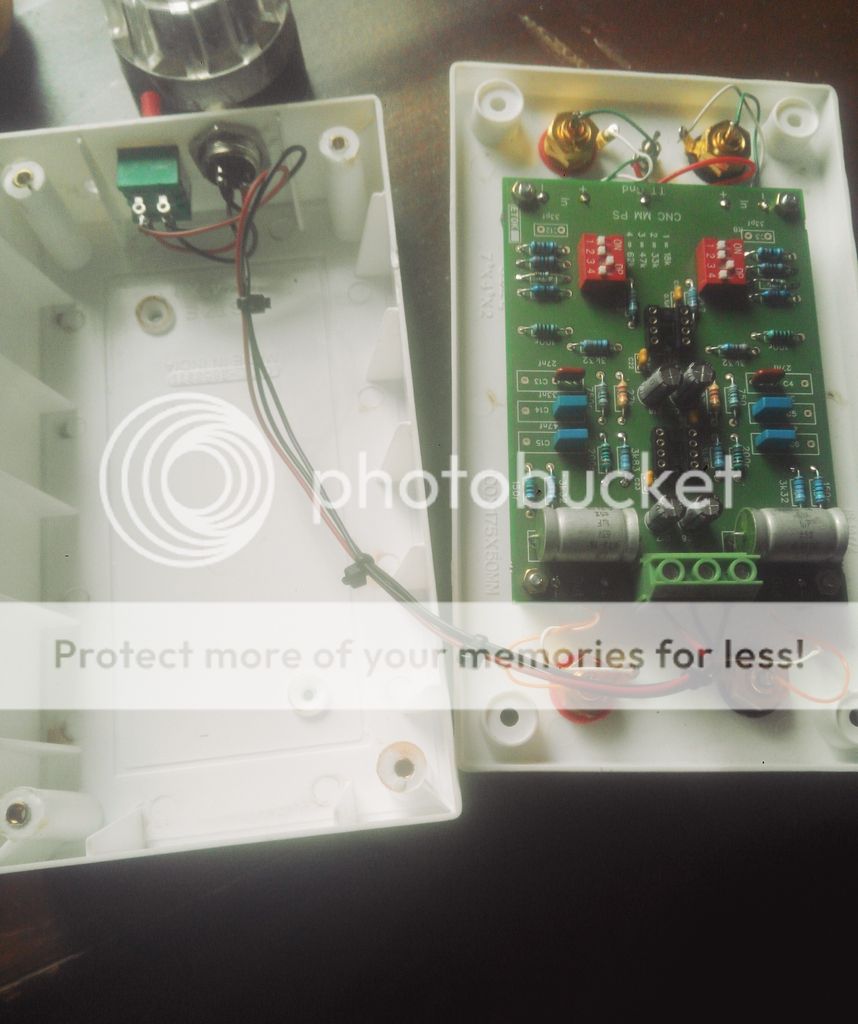

For internal signal cabling my strong recommendation is to use a twisted shielded pair. One of these wires is used for signal positive and the other is obviously the signal negative. The shield of the cable is grounded to the chassis at the source end of the signal path, and kept floating/unconnected at end point of the signal path. To expand on that, assume the cable that connects input RCA socket to your circuit board. The signal flows from RCA socket to PCB. So RCA socket is source in this case, and PCB is the end of the signal flow in this case (we're considering only the segment of signal flow through the cable, and not the complete signal flow). So expose the shield at RCA socket end and short out securely to chassis, and simply cut the shield at the PCB end (marked In+ and In- on the PCB). Similarly, there are a pair of cables from the PCB Out+ and Out- to output RCA sockets. Here the signal starts at the PCB and ends at the output RCA sockets, so short shields at PCB end to chassis, and let shield float at output RCA sockets.

The next thing to take care of is the phono ground point at the PCB. This extends to a screw or binding post on the chassis and must ideally be insulated from the chassis. The phono ground is carried to the turntable by a separate wire.

On the AC power lines that supplies the CNC, the earth must be grounded to equipment chassis and transformer chassis.

There is one further isolation/lift of the power supply, in case you're interested further.

Now, the cables that carry the signal from the turntable to the phono preamp is very, very vulnerable to interferences as the signal is very weak. This is still true even if the cables from turntable to phono preamp are shielded cables. You'll be surprised how much interference gets induced through these cables if run close to other power cables or passed near transformers even when using shielded twisted pairs shielded coax cables. So route the TT's cable as far away from nearby power cables and other electronics like amps.

If you cannot use shielded twisted pairs for internal cabling, use tightly twisted pairs.

Power supply cables inside the cabinet must also be tightly twisted.

Reducing interference in phono preamps is a challenging task at the best of times, so it's best to follow these basic cablng hygienes.