Re: Battery powered DIY CNC phono stage

If you are happy then its fine.

I felt hum noise was more with scheme 1 and for 2, you must have minimum 2.5V difference between input and output. Input mean lower level of ripple. You are measuring peak. No ripple,

12V transformer gives 13.2V unloaded, will result into 18.66V at output with ripple factor it would be 15.5. So regulation could be dependant on capacitor bank discharge rate. This was my point. With load this changes drastically.

Phono stages are notorious in picking hum though CNC is OPAMP based which has higher PSRR. it will will show up.

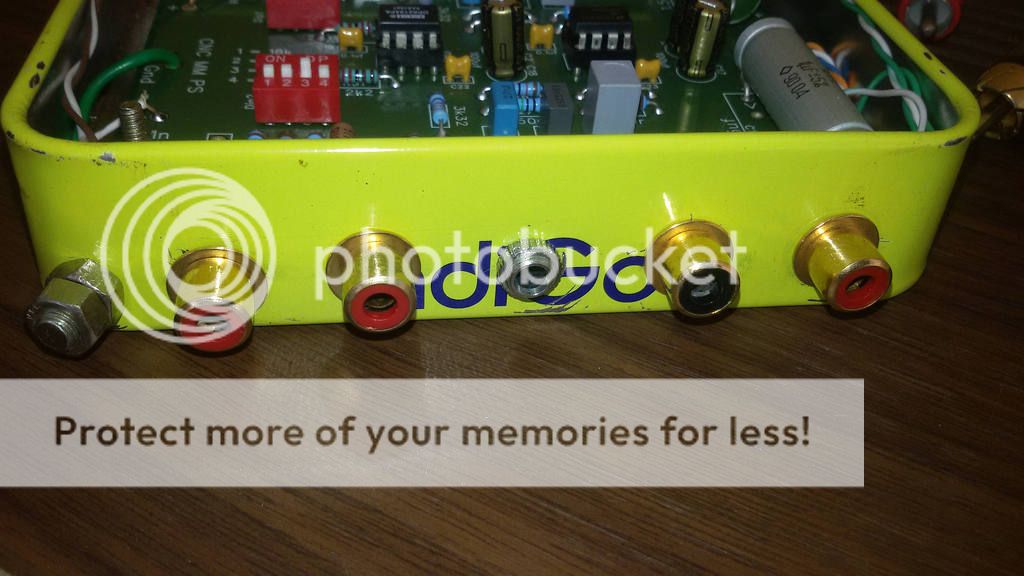

Great points, it works. In the first instance, brother is using a CNC (sachu version) with a 24 volts single rail polycom phone regulated powersupply wired with the same logic. In the second instance, I have tried it with regulation only using 7815 and 7915 regulators, using a 12 volts, 500 ma tranny. The output was 15-0-15.

If you are happy then its fine.

I felt hum noise was more with scheme 1 and for 2, you must have minimum 2.5V difference between input and output. Input mean lower level of ripple. You are measuring peak. No ripple,

12V transformer gives 13.2V unloaded, will result into 18.66V at output with ripple factor it would be 15.5. So regulation could be dependant on capacitor bank discharge rate. This was my point. With load this changes drastically.

Phono stages are notorious in picking hum though CNC is OPAMP based which has higher PSRR. it will will show up.