hi friends,

i'm facing an issue from my K Buffer: while playing music, the volume suddenly dies down and i can only hear feeble sound of music. this was even before i could finalize the chassis etc. after testing for various voltage measurements as specified on preamp board i found that the input voltage of 0,-10 was fine but 10,0 was dead very low was reading something of the order of 0.2 volts.

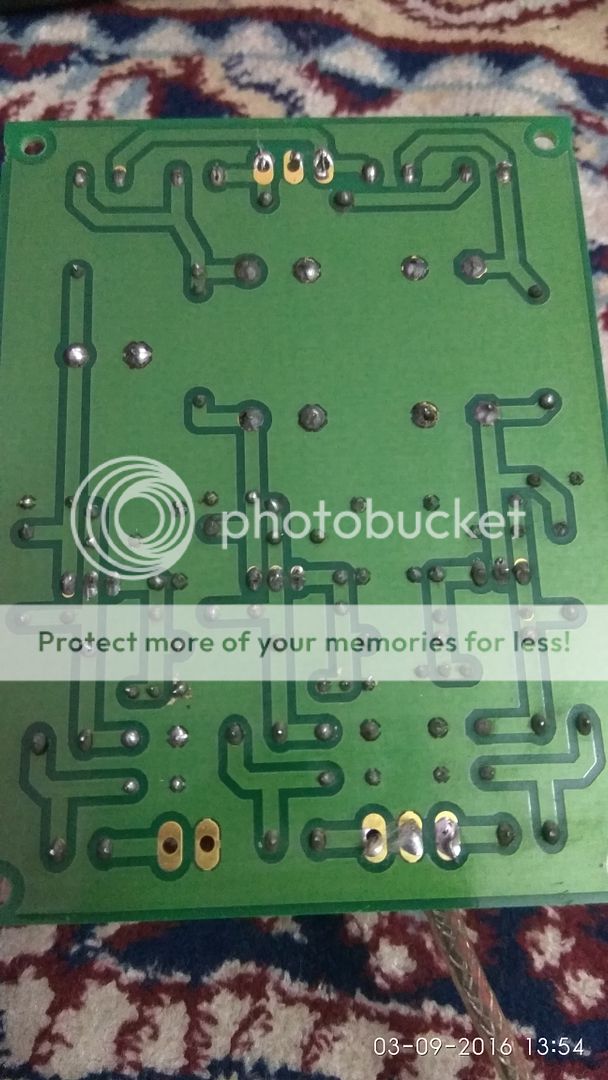

later i traced the issue to one of the 3 trimpots [middle one in the pic] responsible for voltage tuning. if i touch the trimpot it would play just fine [voltages restore] and also i noticed that the trimpot had 5K OHM irrespective of turning the screw. i replaced the trimpot with new one. it had been playing fine for more than a month. but the same issue has reoccurred. this time around i'm planning to replace the trimpot with a resistor [trimpot now measures 2.2K OHMS]. but while playing if i try to measure the resistance on other 2 trimpots on the PSU PCB , my multimeter shows infinite resistance. perplexed, what could be the exact issue?

i'm facing an issue from my K Buffer: while playing music, the volume suddenly dies down and i can only hear feeble sound of music. this was even before i could finalize the chassis etc. after testing for various voltage measurements as specified on preamp board i found that the input voltage of 0,-10 was fine but 10,0 was dead very low was reading something of the order of 0.2 volts.

later i traced the issue to one of the 3 trimpots [middle one in the pic] responsible for voltage tuning. if i touch the trimpot it would play just fine [voltages restore] and also i noticed that the trimpot had 5K OHM irrespective of turning the screw. i replaced the trimpot with new one. it had been playing fine for more than a month. but the same issue has reoccurred. this time around i'm planning to replace the trimpot with a resistor [trimpot now measures 2.2K OHMS]. but while playing if i try to measure the resistance on other 2 trimpots on the PSU PCB , my multimeter shows infinite resistance. perplexed, what could be the exact issue?

Last edited: