You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A 2 way horn project

- Thread starter Vineethkumar01

- Start date

Vineethkumar01

Well-Known Member

Thanks for the suggestion. Please let me know if you have a suggested alignment for this driver.Imo, the Faitalpro will not be suitable for a sealed box due to its low compliance of the suspension. For a sealed box you require a high compliance driver atleast > 1.4mm/ Newton.

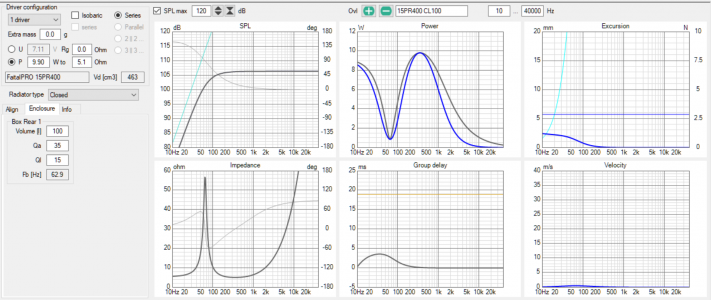

I used a closed box just as a part of this study for now. I am yet to fix a bass alignment for this project. I view this driver more like a lower mid driver than as a proper woofer. So I thought sealed alignment will work to some extent as long as one has proper woofers for the low end. But since the driver is more capable, it seems to do very well in a bass reflex enclosure also as done in Troels' and Tony Gee's projects. Tony gee's type EBS alignment cabinet is unmanageable size for me personally. But Troels' alignment I can tolerate at home.

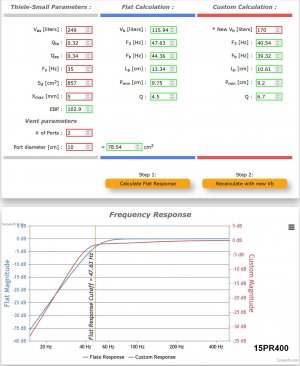

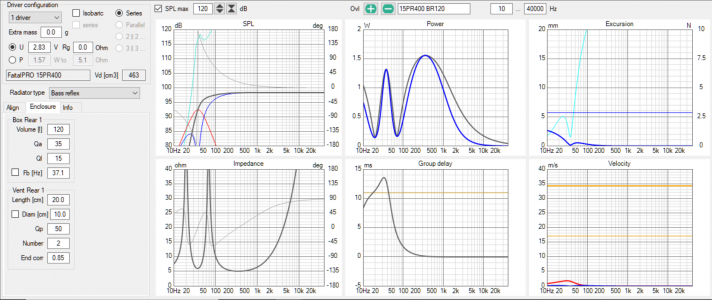

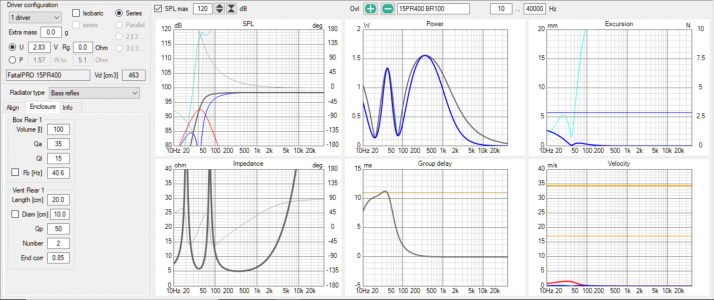

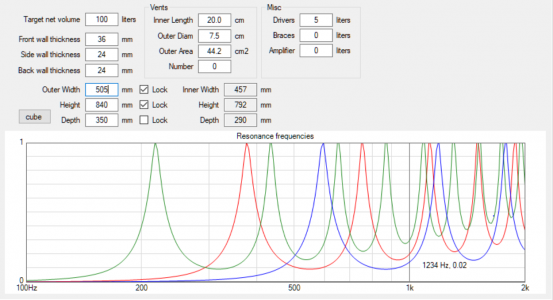

Here is what the driver will do in a Troels' type bass reflex alignment.

STATISTICS

f3 46.9 Hz

f6 37.2 Hz

f10 30.8 Hz

Zmin 5.1 Ohm @ 349 Hz

Zmax 54.8 Ohm @ 19.4 Hz

GDmax 13.6 ms @ 32.2 Hz

XmaxC 3 mm @ 5 Hz

VmaxR 1.9 m/s @ 30.4 Hz

Pmax 1.6 VA @ 349 Hz

-------------------------------------------------------------

DRIVER: FaitalPRO 15PR400, 1 pcs in series

n0 2.73 % Reference efficiency

SPL 96.5 dB/W Sensitivity

USPL 98.4 dB/2.83 Sensitivity

EBP 102.9 Efficiency bandwidth product

Dd 32.0 cm Effective diameter of driver

Vd 462.9 cm^3 Maximum linear volume of displacement

Cas 1.56E-6 m^5/N Acoustic equivalent of Cms

Mas 1.31E1 kg/m^4 Acoustic equivalent of Mms+Mme

Ras 4.8E2 Ns/m^5 Acoustic equivalent of Rms

Rae 8.44E3 Ns/m^5 Acoustic equivalent of Re+Rg

Lces 6.69E-2 H Electrical inductive equivalent of Cas

Cmes 3.05E-4 F Electrical capacitive equivalent of Mas

Res 8.97E1 Ohm Electrical resistive equivalent of Ras

-------------------------------------------------------------

BOX REAR 1: Vb=120.0 l, Ql=15.0

Fb 37.1 Hz System resonance frequency

Cab 8.49E-7 m^5/N Acoustic compliance of air in enclosure

Rab 1.44E2 Ns/m^5 Acoustic resistance due to absorption

Ral 7.58E4 Ns/m^5 Acoustic resistance due to leakage

Lceb 3.66E-2 H Electrical inductive equivalent of Cab

Reb 2.98E2 Ohm Electrical resistive equivalent of Rab

Rel 5.68E-1 Ohm Electrical resistive equivalent of Ral

-------------------------------------------------------------

VENT REAR 1: Dv=10.0 cm, Lv=20.0 cm

Sp 78.5 cm^2 Effective area of port

Map 2.17E1 kg/m^4 Acoustic mass of air in port

Rap 1.01E2 Ns/m^5 Acoustic resistance of port losses

Cmep 5.03E-4 F Electrical capacitive equivalent of Map

Rep 4.26E2 Ohm Electrical resistive equivalent of Rap

Vineethkumar01

Well-Known Member

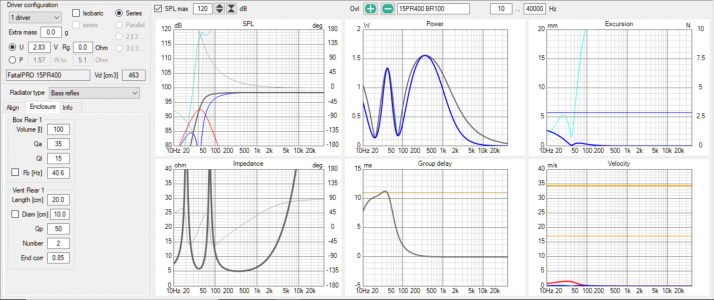

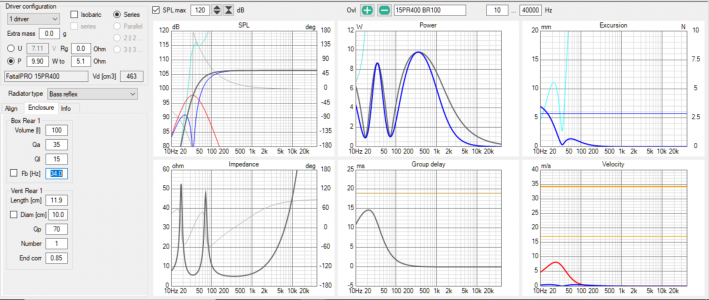

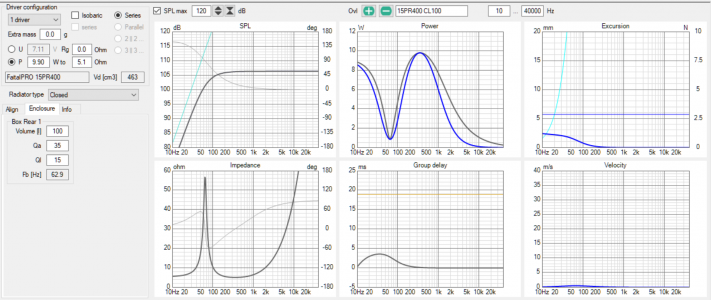

Here is what the driver will do in 100L bass reflex cabinet but with every other spec as in previous post:

STATISTICS

f3 49 Hz

f6 40.6 Hz

f10 33.6 Hz

Zmin 5.1 Ohm @ 349 Hz

Zmax 56.7 Ohm @ 19.7 Hz

GDmax 11.3 ms @ 35.1 Hz

XmaxC 3 mm @ 5 Hz

VmaxR 1.7 m/s @ 32.2 Hz

Pmax 1.6 VA @ 349 Hz

-------------------------------------------------------------

DRIVER: FaitalPRO 15PR400, 1 pcs in series

n0 2.73 % Reference efficiency

SPL 96.5 dB/W Sensitivity

USPL 98.4 dB/2.83 Sensitivity

EBP 102.9 Efficiency bandwidth product

Dd 32.0 cm Effective diameter of driver

Vd 462.9 cm^3 Maximum linear volume of displacement

Cas 1.56E-6 m^5/N Acoustic equivalent of Cms

Mas 1.31E1 kg/m^4 Acoustic equivalent of Mms+Mme

Ras 4.8E2 Ns/m^5 Acoustic equivalent of Rms

Rae 8.44E3 Ns/m^5 Acoustic equivalent of Re+Rg

Lces 6.69E-2 H Electrical inductive equivalent of Cas

Cmes 3.05E-4 F Electrical capacitive equivalent of Mas

Res 8.97E1 Ohm Electrical resistive equivalent of Ras

-------------------------------------------------------------

BOX REAR 1: Vb=100.0 l, Ql=15.0

Fb 40.6 Hz System resonance frequency

Cab 7.08E-7 m^5/N Acoustic compliance of air in enclosure

Rab 1.58E2 Ns/m^5 Acoustic resistance due to absorption

Ral 8.3E4 Ns/m^5 Acoustic resistance due to leakage

Lceb 3.05E-2 H Electrical inductive equivalent of Cab

Reb 2.72E2 Ohm Electrical resistive equivalent of Rab

Rel 5.19E-1 Ohm Electrical resistive equivalent of Ral

-------------------------------------------------------------

VENT REAR 1: Dv=10.0 cm, Lv=20.0 cm

Sp 78.5 cm^2 Effective area of port

Map 2.17E1 kg/m^4 Acoustic mass of air in port

Rap 1.11E2 Ns/m^5 Acoustic resistance of port losses

Cmep 5.03E-4 F Electrical capacitive equivalent of Map

Rep 3.89E2 Ohm Electrical resistive equivalent of Rap

STATISTICS

f3 49 Hz

f6 40.6 Hz

f10 33.6 Hz

Zmin 5.1 Ohm @ 349 Hz

Zmax 56.7 Ohm @ 19.7 Hz

GDmax 11.3 ms @ 35.1 Hz

XmaxC 3 mm @ 5 Hz

VmaxR 1.7 m/s @ 32.2 Hz

Pmax 1.6 VA @ 349 Hz

-------------------------------------------------------------

DRIVER: FaitalPRO 15PR400, 1 pcs in series

n0 2.73 % Reference efficiency

SPL 96.5 dB/W Sensitivity

USPL 98.4 dB/2.83 Sensitivity

EBP 102.9 Efficiency bandwidth product

Dd 32.0 cm Effective diameter of driver

Vd 462.9 cm^3 Maximum linear volume of displacement

Cas 1.56E-6 m^5/N Acoustic equivalent of Cms

Mas 1.31E1 kg/m^4 Acoustic equivalent of Mms+Mme

Ras 4.8E2 Ns/m^5 Acoustic equivalent of Rms

Rae 8.44E3 Ns/m^5 Acoustic equivalent of Re+Rg

Lces 6.69E-2 H Electrical inductive equivalent of Cas

Cmes 3.05E-4 F Electrical capacitive equivalent of Mas

Res 8.97E1 Ohm Electrical resistive equivalent of Ras

-------------------------------------------------------------

BOX REAR 1: Vb=100.0 l, Ql=15.0

Fb 40.6 Hz System resonance frequency

Cab 7.08E-7 m^5/N Acoustic compliance of air in enclosure

Rab 1.58E2 Ns/m^5 Acoustic resistance due to absorption

Ral 8.3E4 Ns/m^5 Acoustic resistance due to leakage

Lceb 3.05E-2 H Electrical inductive equivalent of Cab

Reb 2.72E2 Ohm Electrical resistive equivalent of Rab

Rel 5.19E-1 Ohm Electrical resistive equivalent of Ral

-------------------------------------------------------------

VENT REAR 1: Dv=10.0 cm, Lv=20.0 cm

Sp 78.5 cm^2 Effective area of port

Map 2.17E1 kg/m^4 Acoustic mass of air in port

Rap 1.11E2 Ns/m^5 Acoustic resistance of port losses

Cmep 5.03E-4 F Electrical capacitive equivalent of Map

Rep 3.89E2 Ohm Electrical resistive equivalent of Rap

This will be suitable for sealed box if not used for sub pow frequency and if the box is large with low to medium stuffing. Another option is to try an aperodic loading with medium stuffing in medium volume box.

For bass reflex this driver can boom if driven hard imo. Again the CMS is low for a BR enclosure too. I would have preferred it to be atleast around 0.6mm/ N.

I am not sure what loading is suitable for this driver TBH as they don't fit even in OB requirements. CMS though low (0.24mm/ N) but the Qts is also low (0.32). So OB loading is also ruled out imo.

For bass reflex this driver can boom if driven hard imo. Again the CMS is low for a BR enclosure too. I would have preferred it to be atleast around 0.6mm/ N.

I am not sure what loading is suitable for this driver TBH as they don't fit even in OB requirements. CMS though low (0.24mm/ N) but the Qts is also low (0.32). So OB loading is also ruled out imo.

Hello sir,

I read this thread - and honestly get the feeling that you are taking a tremendous risk, in time and money,.

I also believe that the chances of you coming up with a good design....... is low.

You also have seemingly no DIY wood working capability, and will have to pay someone else to build for you. Is this DIY or HSE ( hire someone else ) ??? ,,,,,,,,, Not ideal !!

Although very popular, I also personally dislike - the idea of a sub woofer.

I do like 15 inch professional quality drivers, but MUCH prefer them to be not just box-loaded, but rather, front horn loaded.

All in all I discourage you from trying to execute an unproven speaker.

I think your basic knowledge and design assumptions are naive.. For example, the best 15 inch horn loaded speaker enclosures I have heard are not limited to 100 litres, but rather, are often in the 300 to 340 litre range, and sometimes larger.

Now...................... to encourage you, and end on a positive note .

One possible suggestion :

Go to the John Inlow Sound website , and select a proven DIY project there. Mr. Inlow knows how to design horns of various types, has decent experience, is honest, and offers reasonable-cost plans. You really need a proven project to do - in my own humble opinion. Have fun.

Best wishes to you,

Jeff

I read this thread - and honestly get the feeling that you are taking a tremendous risk, in time and money,.

I also believe that the chances of you coming up with a good design....... is low.

You also have seemingly no DIY wood working capability, and will have to pay someone else to build for you. Is this DIY or HSE ( hire someone else ) ??? ,,,,,,,,, Not ideal !!

Although very popular, I also personally dislike - the idea of a sub woofer.

I do like 15 inch professional quality drivers, but MUCH prefer them to be not just box-loaded, but rather, front horn loaded.

All in all I discourage you from trying to execute an unproven speaker.

I think your basic knowledge and design assumptions are naive.. For example, the best 15 inch horn loaded speaker enclosures I have heard are not limited to 100 litres, but rather, are often in the 300 to 340 litre range, and sometimes larger.

Now...................... to encourage you, and end on a positive note .

One possible suggestion :

Go to the John Inlow Sound website , and select a proven DIY project there. Mr. Inlow knows how to design horns of various types, has decent experience, is honest, and offers reasonable-cost plans. You really need a proven project to do - in my own humble opinion. Have fun.

Best wishes to you,

Jeff

Last edited:

Vineethkumar01

Well-Known Member

Thank you for your suggestions..Hello sir,

I read this thread - and honestly get the feeling that you are taking a tremendous risk, in time and money,.

I also believe that the chances of you coming up with a good design....... is low.

You also have seemingly no DIY wood working capability, and will have to pay someone else to build for you. Is this DIY or HSE ( hire someone else ) ??? ,,,,,,,,, Not ideal !!

Although very popular, I also personally dislike - the idea of a sub woofer.

I do like 15 inch professional quality drivers, but MUCH prefer them to be not just box-loaded, but rather, front horn loaded.

All in all I discourage you from trying to execute an unproven speaker.

I think your basic knowledge and design assumptions are naive.. For example, the best 15 inch horn loaded speaker enclosures I have heard are not limited to 100 litres, but rather, are often in the 300 to 340 litre range, and sometimes larger.

Now...................... to encourage you, and end on a positive note .

One possible suggestion :

Go to the John Inlow Sound website , and select a proven DIY project there. Mr. Inlow knows how to design horns of various types, has decent experience, is honest, and offers reasonable-cost plans. You really need a proven project to do - in my own humble opinion. Have fun.

Best wishes to you,

Jeff

I agree that to get a full sense of DIY one may do the woodworking part also. In my opinion, woodworking is fun when one has the space, right tools, and skills for it. Skills can be sharpened with practice. Due to the constraints imposed by place where I live, I have no choice but to get help from some one else for the wood-working part. If some one says this is not DIY, I don't care a bit.

You don't like subwoofer's with speakers. Fine. I may. Who knows until I decide for myself.

I agree that from both technical and audible point of view, It makes more sense to go for a full horn build. I may. In future. But not at the moment.

I believe saying things like 15inch woofers are better suited for 350 litre boxes without quantifying/qualifying assumptions about the technical parameters of the drivers is even more naïve. But I do agree with you that the specific driver I have chosen may like large boxes. Of the order of 250 litres or so. But I cannot have that big a box at my home for now. In my opinion, every design is a compromise. With the same driver I have Troels Gravesen used about a 120L box. And he liked it. This kind of smaller sized box is a compromise I am willing to make for now. If I don't find it appealing to my tastes eventually, I have other uses for it.

I am not discouraged by the your opinion of the success of this project. I don't care about whether I succeed or not. In fact I have not even defined a metric to measure the success of this project. In technical terms or audibility-wise. This project is intended to hone my own technical skills regarding speaker building, understand the different aspects involved in more detail and learn more about whatever I currently know and same for who ever else is interested. I do not hope to come out out with statements like 'this is the last speaker i would ever build'. This will be one, there may be more, but with more understanding about my own preferences and with refined technical understanding. I was not born with speaker design skills. Whatever I know I have learnt bit by bit over the past few years with reading and experimentation. And I find my method very satisfying, to me.

Thanks for the encouraging suggestions about Inlow horns. I find them interesting too. I have been going through his site. They may be good. There are plenty others that are also good, maybe even better. But the best horn is not my preference right now. For now I have other plans for the horn. I may move to something else later.

I don't think in the same ways as you. With your post, you make it even more clear to me. Our tastes and musical preferences may differ. Our technical skills differ. Our opinions about what looks good/sounds good may differ.

In short, I am not you.

grindstone

Well-Known Member

Nice driver. Wish I had 2

Inquiries:

- Do you have a max power number in mind? Can we "cheat" toward home/lower-power (say <10W)?

- Are you thinking actual corners (read: boundaries) be used or just the corner cab shape?

- Can you put "footprint" size limit numbers down for consideration (ie max distance from theoretical apex or max L along one wall, etc)?

- If wall/corner location, do you have baseboard/molding that you need to allow for (need/want riser? If so what size out from wall & how tall?) Please check/consider also any close furniture--ie must forward lobe fire over chair/sofa arm, etc.?

- Any preference on directivity besides trying to match horizontals at XO--is less-constant (some beaminess) better for your tastes?

- Any HVAC supply or return vents you need to not block in proposed area(s)?

- Do you have preferences for terminus/vent locations?

- 100% committed to active from the start or will you develop active and build passive (do you strongly care to physically align voice coils by staggering or tilting baffle)? Will it always be high-passed, too? If so, can it be line-level and separate amp?

- What kind of acoustically-absorbent materials might be convenient to use to address standing waves (please don't say 'just foam' )

- Got a link to Troels' 120L previously referenced? I could only find an OB but didn't have time to look harder.

- Are there any local Radian distributors for you?

Thoughts:

- What about something with gasketed cleat frame (and machine screw T-nut etc) for removable baffle (grille frame in front for aesthetics)? Then, make a "furniture-grade" cab for the rest (maybe a rear panel, too, but 2 boards at most for any future changes, say). I have seen people make only a nice top and nice trim pieces/moldings near the floor (is this floor, too, BTW?) and wrap the rest in fabric complementary to the room, etc. It's more work, but the flexibility might be justified in this case (these are really hard configs to do).

- Suggest use of Hornresp, AJHorn, Akabak, MJK sheets, (etc) to better look at axial/longitudinal standing wave/harmonics & offsets.

- Might be worth making some mock-up (cardboard/whatever) and obtaining domestic approval for use in the smaller room. The smaller room will likely "drive" the permissable size. This will be problematic trying to match horizontals at 800 because big horns on little cabs looks funny. Maybe start there and bang-out mouth size for that. Center-to-center in big 2-ways means vertical polars are toast pretty early--it's good to try to aim the bottom vertical null right at floor-bounce if you can jockey the geometry there.

- If you are in a hurry and committed to active, maybe just grab one of the recommended "pro" designs and look at lining/cross-batts & filling (polyester pillow stuffing and fiberglass ok?). Example close to your target: 22.5 x 20 x 17.5 external 4.55 ft3 tune 47 (F3 48), 2 ports 4" Dp 2-3/8" Lp

- Not sure it's worth it w/o going after more bass, but understand your position & you already have the nice drivers. What it plays, it can do w/o moving very far (clean).

Maybe think some when you get the chance and please keep us posted.

Inquiries:

- Do you have a max power number in mind? Can we "cheat" toward home/lower-power (say <10W)?

- Are you thinking actual corners (read: boundaries) be used or just the corner cab shape?

- Can you put "footprint" size limit numbers down for consideration (ie max distance from theoretical apex or max L along one wall, etc)?

- If wall/corner location, do you have baseboard/molding that you need to allow for (need/want riser? If so what size out from wall & how tall?) Please check/consider also any close furniture--ie must forward lobe fire over chair/sofa arm, etc.?

- Any preference on directivity besides trying to match horizontals at XO--is less-constant (some beaminess) better for your tastes?

- Any HVAC supply or return vents you need to not block in proposed area(s)?

- Do you have preferences for terminus/vent locations?

- 100% committed to active from the start or will you develop active and build passive (do you strongly care to physically align voice coils by staggering or tilting baffle)? Will it always be high-passed, too? If so, can it be line-level and separate amp?

- What kind of acoustically-absorbent materials might be convenient to use to address standing waves (please don't say 'just foam' )

- Got a link to Troels' 120L previously referenced? I could only find an OB but didn't have time to look harder.

- Are there any local Radian distributors for you?

Thoughts:

- What about something with gasketed cleat frame (and machine screw T-nut etc) for removable baffle (grille frame in front for aesthetics)? Then, make a "furniture-grade" cab for the rest (maybe a rear panel, too, but 2 boards at most for any future changes, say). I have seen people make only a nice top and nice trim pieces/moldings near the floor (is this floor, too, BTW?) and wrap the rest in fabric complementary to the room, etc. It's more work, but the flexibility might be justified in this case (these are really hard configs to do).

- Suggest use of Hornresp, AJHorn, Akabak, MJK sheets, (etc) to better look at axial/longitudinal standing wave/harmonics & offsets.

- Might be worth making some mock-up (cardboard/whatever) and obtaining domestic approval for use in the smaller room. The smaller room will likely "drive" the permissable size. This will be problematic trying to match horizontals at 800 because big horns on little cabs looks funny. Maybe start there and bang-out mouth size for that. Center-to-center in big 2-ways means vertical polars are toast pretty early--it's good to try to aim the bottom vertical null right at floor-bounce if you can jockey the geometry there.

- If you are in a hurry and committed to active, maybe just grab one of the recommended "pro" designs and look at lining/cross-batts & filling (polyester pillow stuffing and fiberglass ok?). Example close to your target: 22.5 x 20 x 17.5 external 4.55 ft3 tune 47 (F3 48), 2 ports 4" Dp 2-3/8" Lp

- Not sure it's worth it w/o going after more bass, but understand your position & you already have the nice drivers. What it plays, it can do w/o moving very far (clean).

Maybe think some when you get the chance and please keep us posted.

Vineethkumar01

Well-Known Member

Hi,

That is quite a lot of questions. But worth pondering over. Really appreciate you asking these..

1) Do you have a max power number in mind? Can we "cheat" toward home/lower-power (say <10W)?

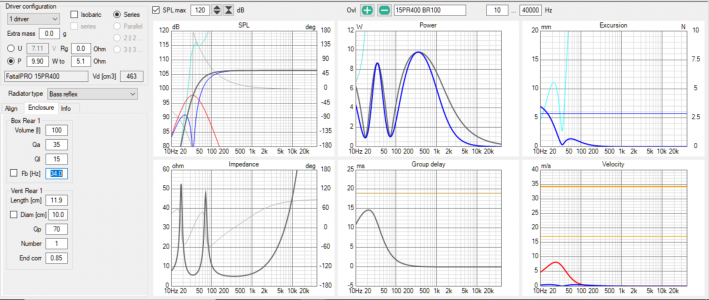

I don't have fixed number of Watts in mind. But based on the bass-alignments I have in mind, I think 10 clean watts would be more than enough looking at SPLs seen in below pics:

left pic: bass reflex, right pic: closed box

If I ever try to experiment with a Linkwitz transform in the closed box, I will definitely need more. But I really don't want this driver to struggle trying to reproduce frequencies below 80Hz.

2) Are you thinking actual corners (read: boundaries) be used or just the corner cab shape?

Currently just looking at a corner cabinet shape. Inspiration comes from here. Samples pics attached (But want to study about boundary effects using this planned prototype speaker also ):

):

View attachment 68132

3) If wall/corner location, do you have baseboard/molding that you need to allow for (need/want riser? If so what size out from wall & how tall?) Please check/consider also any close furniture--ie must forward lobe fire over chair/sofa arm, etc.?

At my listening position, I the chair that I usually sit for listening to music, my ear height from ground is about 105cm. Hence I would ideally want the horn's center to be around this height, cabinet dimensions, specifically cabinet height needs to facilitate this criterion given that the first horn I will partner with the woofer cabinet will have narrow vertical directivity.

4) Any preference on directivity besides trying to match horizontals at XO--is less-constant (some beaminess) better for your tastes?

As of now, my approach to a speaker design is to take care of directivity matching properly, while also ensuring good time domain response. Hence I have not yet discovered my preferred directivity index in the kind of rooms I listen to music. In fact the entire exercise of building this particular project along with a wider radiating design here: https://www.hifivision.com/threads/a-3-way-active-crossover-design-study.86092/ and https://www.diyaudio.com/community/threads/a-3-way-design-study.376620/ is to discover my tastes in speakers, controlled directivity designs at least to some extent. Future plans include a coaxial top with this/twin SB acoustics Satori WO24P-8 based woofer modules.

Future plans include a coaxial top with this/twin SB acoustics Satori WO24P-8 based woofer modules.

5) Any HVAC supply or return vents you need to not block in proposed area(s)?

None

6) Do you have preferences for terminus/vent locations?

No preferences based on where they are in the cabinet. Only preference is that it/they should properly do their job and not cause too much port pipe resonances, if at all I use them.

7) 100% committed to active from the start or will you develop active and build passive (do you strongly care to physically align voice coils by staggering or tilting baffle)? Will it always be high-passed, too? If so, can it be line-level and separate amp?

I am more comfortable playing around with active filters. I regularly design/use IIR and FIR digital filters on my job. Hence more easy for me to work with them. I have found that the convenience and tweakability offered by a DSP crossover cannot be matched by a passive crossover or analog active crossover. I may switch to passive if it feels good enough upon experimentation. I don't much care about physically aligning voice coils since I have a DSP. All drivers will have individual amps powering them and I have a 6 channel DSP for now. I also want to have the flexibiity/ability to EQ out EQuable (linear time invariant) artifacts in the frequency response of the drivers. DSP makes this easy.

8) What kind of acoustically-absorbent materials might be convenient to use to address standing waves (please don't say 'just foam' )?

I am looking for wool/polyfill for filling the sealed cabinet (for closed). Ideas come from here: https://www.somasonus.net/box-construction-methods and https://drive.google.com/file/d/16j...HBYpgMJO73OIZ4YJgwjsHomC3o2sU1Sia13nuAgPZOfWM

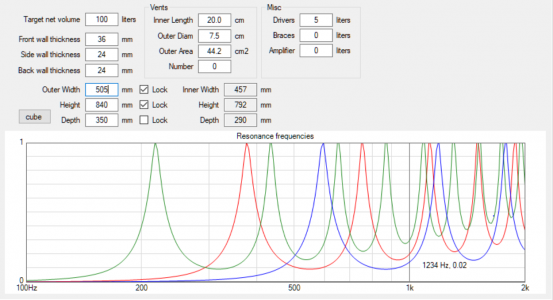

and my discussions with FM augerpro over at diyaudio forum. Not planning to use foam, at least as of now. Don't want to use fiberglass material unless it is necessary. Also not planning to use a cuboidal shaped cabinet for now. Trying to minimize parallel walls. I even like the looks. I use VituixCAD to study about port pipe resonances and axial modes in the cabinet. Eg here for axial modes in a closed cuboidal cabinet:

9) Got a link to Troels' 120L previously referenced? I could only find an OB but didn't have time to look harder.

Here it is:

10) What about something with gasketed cleat frame (and machine screw T-nut etc) for removable baffle (grille frame in front for aesthetics)? Then, make a "furniture-grade" cab for the rest (maybe a rear panel, too, but 2 boards at most for any future changes, say). I have seen people make only a nice top and nice trim pieces/moldings near the floor (is this floor, too, BTW?) and wrap the rest in fabric complementary to the room, etc. It's more work, but the flexibility might be justified in this case (these are really hard configs to do)

I will think along these lines

11) Suggest use of Hornresp, AJHorn, Akabak, MJK sheets, (etc) to better look at axial/longitudinal standing wave/harmonics & offsets.

Thanks. I will look into other softwares when I reach a point where VituixCAD becomes limited. Had used a bit of hornresp in the past, may use it again if needed. Akabak, I have to learn

12) Might be worth making some mock-up (cardboard/whatever) and obtaining domestic approval for use in the smaller room. The smaller room will likely "drive" the permissable size. This will be problematic trying to match horizontals at 800 because big horns on little cabs looks funny. Maybe start there and bang-out mouth size for that. Center-to-center in big 2-ways means vertical polars are toast pretty early--it's good to try to aim the bottom vertical null right at floor-bounce if you can jockey the geometry there.

Cardboard/foam board mock up already done and got approval

As you said, C-C approx 1/4x wavelength at crossover is long gone. I am looking at around 1-1.4x C-C at crossover wavelength (Kimmo's "thumb rule" For more details about its advantages and disadvantages, please read here from post no 312: http://www.htguide.com/forum/showthread.php?44128-VituixCAD-v2/page9 ). 20cm woofer radius + 5-10cm distance from woofer frame edge to cabinet top edge + 10cm from cabinet edge till horn centre (for this horn: https://josephcrowe.com/products/copy-of-es-600-bi-radial-wood-horn) means a total distance of about 40+cm C-C between the radiators. 800Hz has 43cm wavelength. Nicely in the ballpark range. For now, I want to play around with radial horns like ES 600 and Yuichi A 290 in configurations like this: https://www.diyaudio.com/community/...aker-build-abec-modelling.357792/post-6883288

For more details about its advantages and disadvantages, please read here from post no 312: http://www.htguide.com/forum/showthread.php?44128-VituixCAD-v2/page9 ). 20cm woofer radius + 5-10cm distance from woofer frame edge to cabinet top edge + 10cm from cabinet edge till horn centre (for this horn: https://josephcrowe.com/products/copy-of-es-600-bi-radial-wood-horn) means a total distance of about 40+cm C-C between the radiators. 800Hz has 43cm wavelength. Nicely in the ballpark range. For now, I want to play around with radial horns like ES 600 and Yuichi A 290 in configurations like this: https://www.diyaudio.com/community/...aker-build-abec-modelling.357792/post-6883288

If I go for another horn top, an axisymmetric waveguide/horn, I will use a freestanding configuration like this: https://www.diyaudio.com/community/...aker-build-abec-modelling.357792/post-6510277

Thought process and leanring more about horns is in progress: current favourate resources:

https://sphericalhorns.net/ , https://kolbrek.hornspeakersystems.info/ , https://www.diyaudio.com/community/threads/acoustic-horn-design-the-easy-way-ath4.338806/

Regarding floor bounce null, Toole says without floor bounce, it feels un natural, maybe for him. I will experiment and find my preference. I will also play around with nice room boundary interference simulator in VituixCAD to learn more..

13) If you are in a hurry and committed to active, maybe just grab one of the recommended "pro" designs and look at lining/cross-batts & filling (polyester pillow stuffing and fiberglass ok?). Example close to your target: 22.5 x 20 x 17.5 external 4.55 ft3 tune 47 (F3 48), 2 ports 4" Dp 2-3/8" Lp

Thanks. But this project is supposed to be a learning experience and discovery build for me. So dont want to go with established "pro" designs

But this project is supposed to be a learning experience and discovery build for me. So dont want to go with established "pro" designs

14) Not sure it's worth it w/o going after more bass, but understand your position & you already have the nice drivers. What it plays, it can do w/o moving very far (clean).

Still contemplating on the bass alignment. I may not use bass reflex (bass reflex with closed ports gives closed to sealed box performace?), closed with Linkwitz transform with low max SPL options If I feel it doesnt suit my tastes. I dont want to bother the driver with much low bass too..

Thanks

Vineeth

That is quite a lot of questions. But worth pondering over. Really appreciate you asking these..

1) Do you have a max power number in mind? Can we "cheat" toward home/lower-power (say <10W)?

I don't have fixed number of Watts in mind. But based on the bass-alignments I have in mind, I think 10 clean watts would be more than enough looking at SPLs seen in below pics:

left pic: bass reflex, right pic: closed box

If I ever try to experiment with a Linkwitz transform in the closed box, I will definitely need more. But I really don't want this driver to struggle trying to reproduce frequencies below 80Hz.

2) Are you thinking actual corners (read: boundaries) be used or just the corner cab shape?

Currently just looking at a corner cabinet shape. Inspiration comes from here. Samples pics attached (But want to study about boundary effects using this planned prototype speaker also

DIY-project: JBL Kebnekaise S4365 - Page 12

This will be my first DIY-project. It will be kind of "open source", so I hope all you guys can ship in with ideas, thoughts and help :) Components at hand: 476mg compression driver H4365 horn 1501fe woofer 4365 speaker grills dbx4820 dsp Crown CTS-1200 amps

www.audioheritage.org

3) If wall/corner location, do you have baseboard/molding that you need to allow for (need/want riser? If so what size out from wall & how tall?) Please check/consider also any close furniture--ie must forward lobe fire over chair/sofa arm, etc.?

At my listening position, I the chair that I usually sit for listening to music, my ear height from ground is about 105cm. Hence I would ideally want the horn's center to be around this height, cabinet dimensions, specifically cabinet height needs to facilitate this criterion given that the first horn I will partner with the woofer cabinet will have narrow vertical directivity.

4) Any preference on directivity besides trying to match horizontals at XO--is less-constant (some beaminess) better for your tastes?

As of now, my approach to a speaker design is to take care of directivity matching properly, while also ensuring good time domain response. Hence I have not yet discovered my preferred directivity index in the kind of rooms I listen to music. In fact the entire exercise of building this particular project along with a wider radiating design here: https://www.hifivision.com/threads/a-3-way-active-crossover-design-study.86092/ and https://www.diyaudio.com/community/threads/a-3-way-design-study.376620/ is to discover my tastes in speakers, controlled directivity designs at least to some extent.

5) Any HVAC supply or return vents you need to not block in proposed area(s)?

None

6) Do you have preferences for terminus/vent locations?

No preferences based on where they are in the cabinet. Only preference is that it/they should properly do their job and not cause too much port pipe resonances, if at all I use them.

7) 100% committed to active from the start or will you develop active and build passive (do you strongly care to physically align voice coils by staggering or tilting baffle)? Will it always be high-passed, too? If so, can it be line-level and separate amp?

I am more comfortable playing around with active filters. I regularly design/use IIR and FIR digital filters on my job. Hence more easy for me to work with them. I have found that the convenience and tweakability offered by a DSP crossover cannot be matched by a passive crossover or analog active crossover. I may switch to passive if it feels good enough upon experimentation. I don't much care about physically aligning voice coils since I have a DSP. All drivers will have individual amps powering them and I have a 6 channel DSP for now. I also want to have the flexibiity/ability to EQ out EQuable (linear time invariant) artifacts in the frequency response of the drivers. DSP makes this easy.

8) What kind of acoustically-absorbent materials might be convenient to use to address standing waves (please don't say 'just foam' )?

I am looking for wool/polyfill for filling the sealed cabinet (for closed). Ideas come from here: https://www.somasonus.net/box-construction-methods and https://drive.google.com/file/d/16j...HBYpgMJO73OIZ4YJgwjsHomC3o2sU1Sia13nuAgPZOfWM

and my discussions with FM augerpro over at diyaudio forum. Not planning to use foam, at least as of now. Don't want to use fiberglass material unless it is necessary. Also not planning to use a cuboidal shaped cabinet for now. Trying to minimize parallel walls. I even like the looks. I use VituixCAD to study about port pipe resonances and axial modes in the cabinet. Eg here for axial modes in a closed cuboidal cabinet:

9) Got a link to Troels' 120L previously referenced? I could only find an OB but didn't have time to look harder.

Here it is:

10) What about something with gasketed cleat frame (and machine screw T-nut etc) for removable baffle (grille frame in front for aesthetics)? Then, make a "furniture-grade" cab for the rest (maybe a rear panel, too, but 2 boards at most for any future changes, say). I have seen people make only a nice top and nice trim pieces/moldings near the floor (is this floor, too, BTW?) and wrap the rest in fabric complementary to the room, etc. It's more work, but the flexibility might be justified in this case (these are really hard configs to do)

I will think along these lines

11) Suggest use of Hornresp, AJHorn, Akabak, MJK sheets, (etc) to better look at axial/longitudinal standing wave/harmonics & offsets.

Thanks. I will look into other softwares when I reach a point where VituixCAD becomes limited. Had used a bit of hornresp in the past, may use it again if needed. Akabak, I have to learn

12) Might be worth making some mock-up (cardboard/whatever) and obtaining domestic approval for use in the smaller room. The smaller room will likely "drive" the permissable size. This will be problematic trying to match horizontals at 800 because big horns on little cabs looks funny. Maybe start there and bang-out mouth size for that. Center-to-center in big 2-ways means vertical polars are toast pretty early--it's good to try to aim the bottom vertical null right at floor-bounce if you can jockey the geometry there.

Cardboard/foam board mock up already done and got approval

As you said, C-C approx 1/4x wavelength at crossover is long gone. I am looking at around 1-1.4x C-C at crossover wavelength (Kimmo's "thumb rule"

If I go for another horn top, an axisymmetric waveguide/horn, I will use a freestanding configuration like this: https://www.diyaudio.com/community/...aker-build-abec-modelling.357792/post-6510277

Thought process and leanring more about horns is in progress: current favourate resources:

https://sphericalhorns.net/ , https://kolbrek.hornspeakersystems.info/ , https://www.diyaudio.com/community/threads/acoustic-horn-design-the-easy-way-ath4.338806/

Regarding floor bounce null, Toole says without floor bounce, it feels un natural, maybe for him. I will experiment and find my preference. I will also play around with nice room boundary interference simulator in VituixCAD to learn more..

13) If you are in a hurry and committed to active, maybe just grab one of the recommended "pro" designs and look at lining/cross-batts & filling (polyester pillow stuffing and fiberglass ok?). Example close to your target: 22.5 x 20 x 17.5 external 4.55 ft3 tune 47 (F3 48), 2 ports 4" Dp 2-3/8" Lp

Thanks.

14) Not sure it's worth it w/o going after more bass, but understand your position & you already have the nice drivers. What it plays, it can do w/o moving very far (clean).

Still contemplating on the bass alignment. I may not use bass reflex (bass reflex with closed ports gives closed to sealed box performace?), closed with Linkwitz transform with low max SPL options If I feel it doesnt suit my tastes. I dont want to bother the driver with much low bass too..

Thanks

Vineeth

Attachments

Last edited:

The impedance double hump looks perfect in both sims. Please remember there will be room gain, so going lower and maximally flat will cause problems in average sized rooms ~ 150-200 sq.ft. That's been my experience.

Running a sim on MJK's worksheets is a great idea

Running a sim on MJK's worksheets is a great idea

Vineethkumar01

Well-Known Member

Thanks for the suggestions.The impedance double hump looks perfect in both sims. Please remember there will be room gain, so going lower and maximally flat will cause problems in average sized rooms ~ 150-200 sq.ft. That's been my experience.

Running a sim on MJK's worksheets is a great idea

I am not aiming for a maximally flat alignment. In fact the closed box Qtc is around 0.58.

With the same cabinet and bass reflex, the response looks kind of maximally flatish.. But that is a compromise with this sized box, I guess. In room response gain at low frequencies need to be taken into account as you rightly suggested. I will try to take care of some of it in the baffle step compensation EQ.

I am trying to have ports in the cabinet but with the option of closing them and running closed box like when needed. Or at least that is the current thought. Room EQ and some treatment is necessary. I will focus on those later.

Another issue to be investigated is boundary interference related. Some of it can be easily seen in VituixCAD.

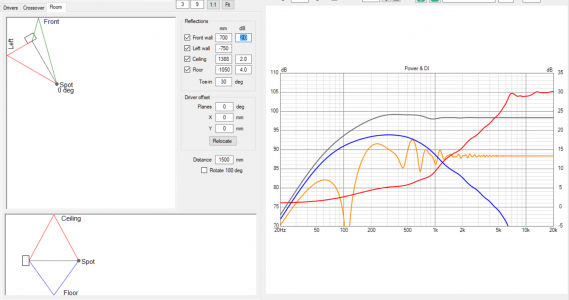

Here is an example:

VituixCAD considers reflections from Front wall, left wall, ceiling, and floor. It includes toe in angles, absorption at every surface etc as shown in left side of above pic. Then it applies the resultant comb filter on the anechoic response to predict the in room response. In the above pic, orange colored curve is the in room response (downshifted by -10dB to fit in the window). We can see the effect of the different comb filters for the speaker location specified via distances from boundaries on left side of pic. Black curve is on-axis anechoic. Blue curve is power response, red curve is sound power directivity.

The tool is limited to the most significant reflections. But there are limitations with every modeling software. However it is a very useful tool to understand the effect of major boundary interferences on the in room response.

Of course, the above is just simulated data. The tool becomes even more useful with measured, full polar frequency response data.

Thanks

Vineeth

Last edited:

Creating the flexible port option is a good idea. Why don't you start building? The outcome rarely "does not" satisfy

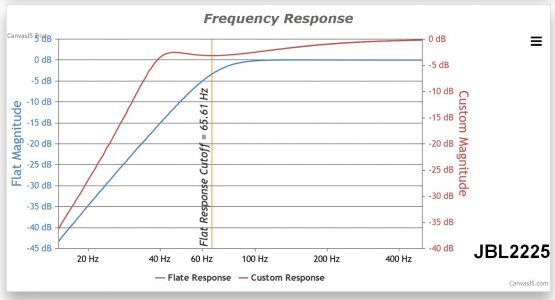

I've been comparing the 15PR400 to a JBL 2225 driver for a 4way ~ JBL 43xx style monitor build. Since the JBl midrange (2121 /2122) is practically impossible to get or horrendously expensive, I decided to go with an Altec (802d) /F.Pro (10PR320) /JBL (2225). The UHF & horn is undecided.

My sims on the 15PR400 show a decent output down to 40hz which I think will be fine for music, don't care for HT. The cabinet is larger than your's though - 40x24x18.5 (8.2 Cu.ft). After the midrange chamber, horn profile and bracing etc, I expect to get at least 6.6 cu.ft (170lt.). I know the 40hz response is -2dB down but think it will be fine in room, otherwise DSP it . By the way, the 2225 also is -3dB down at 40hz.

. By the way, the 2225 also is -3dB down at 40hz.

Sorry, I know that's not much help but realzied it was the same driver and though I'd add what I could.

I've been comparing the 15PR400 to a JBL 2225 driver for a 4way ~ JBL 43xx style monitor build. Since the JBl midrange (2121 /2122) is practically impossible to get or horrendously expensive, I decided to go with an Altec (802d) /F.Pro (10PR320) /JBL (2225). The UHF & horn is undecided.

My sims on the 15PR400 show a decent output down to 40hz which I think will be fine for music, don't care for HT. The cabinet is larger than your's though - 40x24x18.5 (8.2 Cu.ft). After the midrange chamber, horn profile and bracing etc, I expect to get at least 6.6 cu.ft (170lt.). I know the 40hz response is -2dB down but think it will be fine in room, otherwise DSP it

Sorry, I know that's not much help but realzied it was the same driver and though I'd add what I could.

Attachments

grindstone

Well-Known Member

Thank you for your reply, Vineeth, it was very helpful--now I understand what particular kind of speaker you are building and what your thread is doing. Thanks also for taking time to search-out and post the links. One of the most wonderful things for me personally is finding this community sharing ever-so-slightly different information than I find in my "normal" reading (and largely with a decorum long-since extinct elsewhere).

Everyone must make their own choice about CTC summing criteria (and everything else) and processors effectively void tough spacing decisions regarding phase shift, but it is great that you are committed to vcad and real data. It is also good to try to leave space above a driver IMO to "breathe" and allow lining, etc., but, in big 2-ways, my view is that offsetting to keep standing waves from messing-up mids should "win". Almost anything can be smacked-flat with damping or processing but at some cost to the level and to the "presentation". OTOH, most people (including me) seem to prefer a little ripple for reasons I may never discover. For passives, that becomes a balance vs. transients but you should be able to nail both with the hardware and amps. It is also at least 50%-good that you are reading Toole

This will all be fun to watch and I'd like to thank you for posting and sharing your process. My only "fear" for you (need a better word, but...) is that you might miss some of the larger cone experience making a sealed cab. Please don't misunderstand--I am certain you will end-up with a very fine speaker, it's just a different kind of speaker, you know? We all have to do what works in our environments, though--so that has to win in the end. Still thinking that the more "flexible" cabinet type/replaceable baffle could serve as a platform to investigate many things while only re-making baffles. OTOH, history would say I am wrong at least once every single day. FWIW. It's just that, despite still being new here, if I had to bet money about who here will build another speaker, I'd feel safe betting on you (well okay and Hari, too)

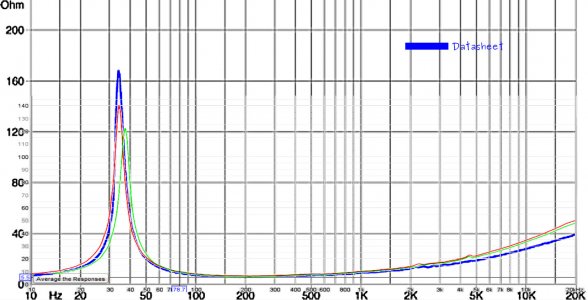

Oh--overlaid your Z curves with the factory sheet I had.

Everyone must make their own choice about CTC summing criteria (and everything else) and processors effectively void tough spacing decisions regarding phase shift, but it is great that you are committed to vcad and real data. It is also good to try to leave space above a driver IMO to "breathe" and allow lining, etc., but, in big 2-ways, my view is that offsetting to keep standing waves from messing-up mids should "win". Almost anything can be smacked-flat with damping or processing but at some cost to the level and to the "presentation". OTOH, most people (including me) seem to prefer a little ripple for reasons I may never discover. For passives, that becomes a balance vs. transients but you should be able to nail both with the hardware and amps. It is also at least 50%-good that you are reading Toole

This will all be fun to watch and I'd like to thank you for posting and sharing your process. My only "fear" for you (need a better word, but...) is that you might miss some of the larger cone experience making a sealed cab. Please don't misunderstand--I am certain you will end-up with a very fine speaker, it's just a different kind of speaker, you know? We all have to do what works in our environments, though--so that has to win in the end. Still thinking that the more "flexible" cabinet type/replaceable baffle could serve as a platform to investigate many things while only re-making baffles. OTOH, history would say I am wrong at least once every single day. FWIW. It's just that, despite still being new here, if I had to bet money about who here will build another speaker, I'd feel safe betting on you (well okay and Hari, too)

Oh--overlaid your Z curves with the factory sheet I had.

Attachments

Check out our special offers on Stereo Package & Bundles for all budget types.