My speaker quest started off with grand ambitions of finding a fancy 3 or 4-way active setup. Luckily, @Vineethkumar01 , the voice of reason, drilled some sense into me, urging us to go for something simple enough with better chances of success (or lesser chances of screwing up). The goal was to create a high-efficiency horn-based design, complete with active crossovers and DSP.

Enter @Vineethkumar01 , the bringer of audio enlightenment, who mentioned this brand spanking new redesign with improved directivity of Yuichi Arai's 290 called the mk3b2 Radial Fin Horn. It's a collaborative masterpiece from the minds of DonVK, docali, and fluid over at DIYaudio.com. We didn't waste any time, we quickly decided that this was the one we were going to attempt. And so, we begin this project with a dash of enthusiasm and a sprinkle of uncertainty!

Particulars:

Action sequence:

Enter @Vineethkumar01 , the bringer of audio enlightenment, who mentioned this brand spanking new redesign with improved directivity of Yuichi Arai's 290 called the mk3b2 Radial Fin Horn. It's a collaborative masterpiece from the minds of DonVK, docali, and fluid over at DIYaudio.com. We didn't waste any time, we quickly decided that this was the one we were going to attempt. And so, we begin this project with a dash of enthusiasm and a sprinkle of uncertainty!

Particulars:

- Drivers: HF: FaitalPRO HF146

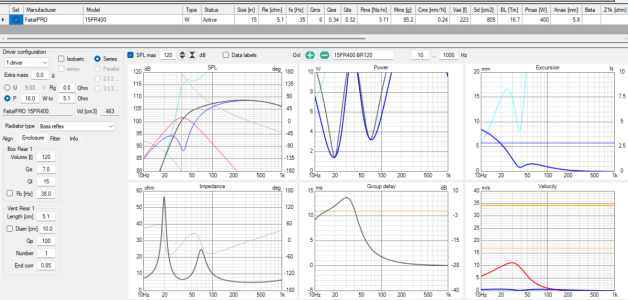

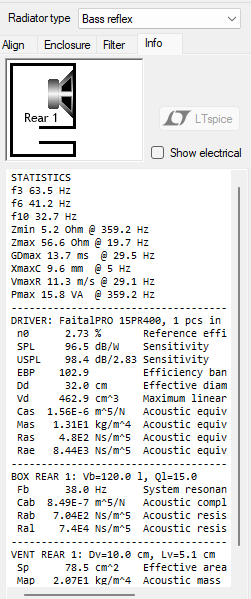

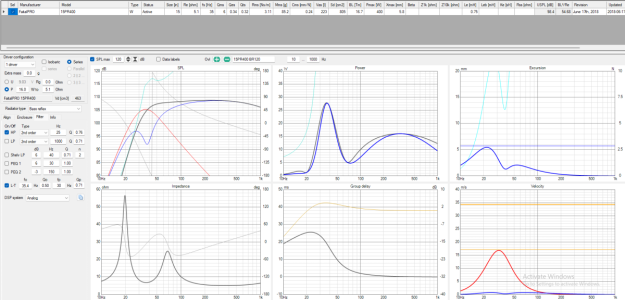

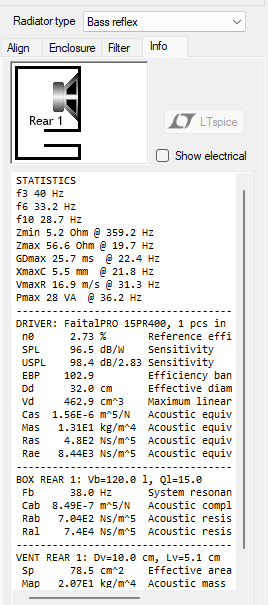

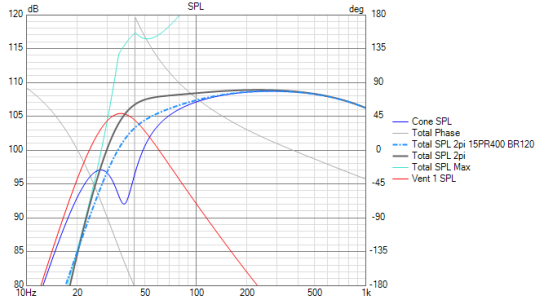

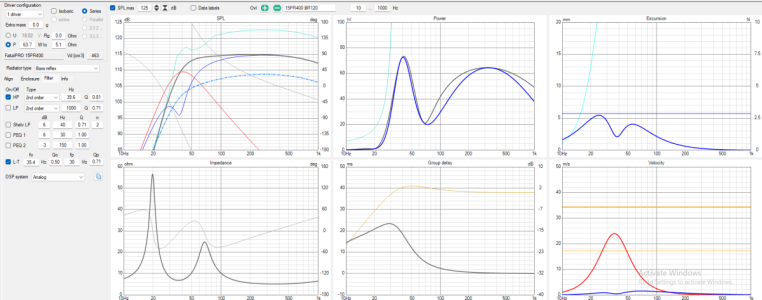

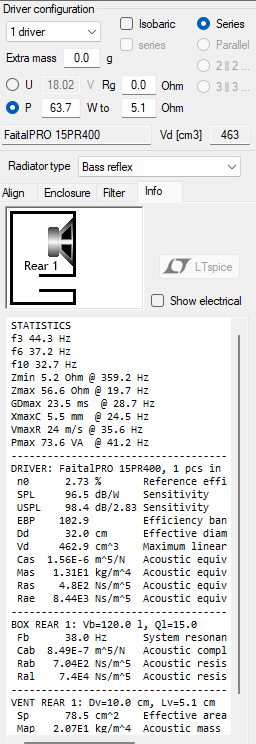

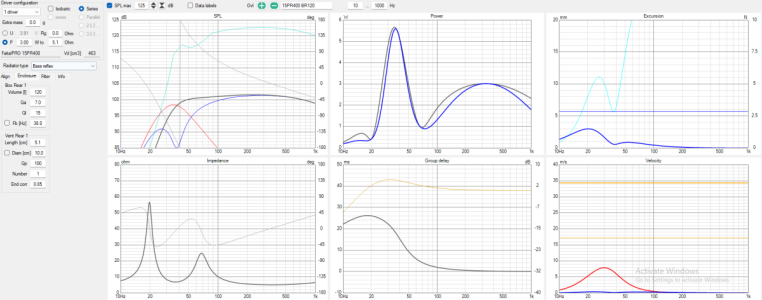

- Bass Reflex cab with 120 Nett volume with F3 at 38Hz.

Action sequence:

- Build the horn first. Which will include 3d printing and CNC.

- Design and execute the adaptor for the CD.

- Design and build the BR cab to suit the horn dimensions.

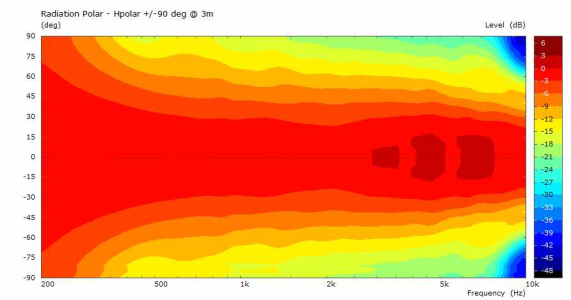

- Extensively measure the horn and create a full spinorama.

- Set the crossover and tune with DSP.

Last edited: