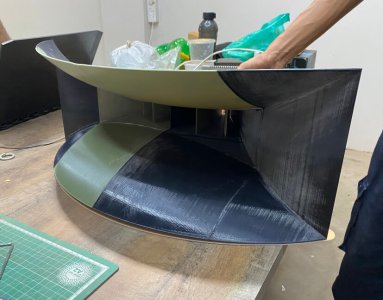

So we did extensive measurements of the horn with the Faital pro HF146 compression driver.

A lot of hardwork went into getting these measurements.

Just Hats off to

@aeroash for doing a hell lot of hardwork for this on a sunday

So here are the measurements. Enjoy..

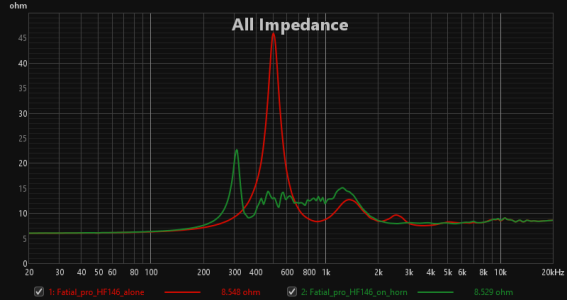

Impedance measurements of the driver without and with the horn

View attachment 78188

Here is the measurement set up for horizontal polars (Mic 2m away from horn)

View attachment 78185

Cleanness of impulse response for on-axis measurement

View attachment 78186

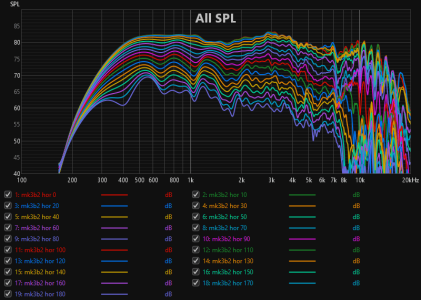

Raw measurements (0 degrees to 180 degrees off axis) gated at 6ms

View attachment 78187

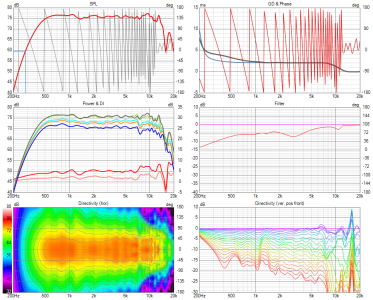

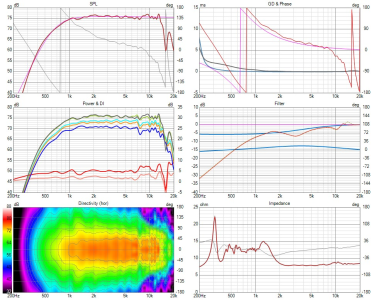

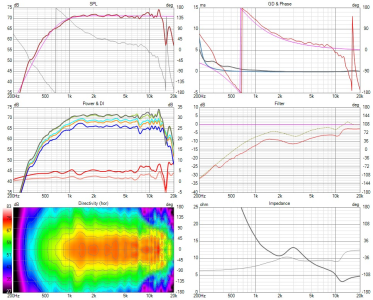

Spinorma data with frequency response flattening equalization applied.

View attachment 78190

View attachment 78189

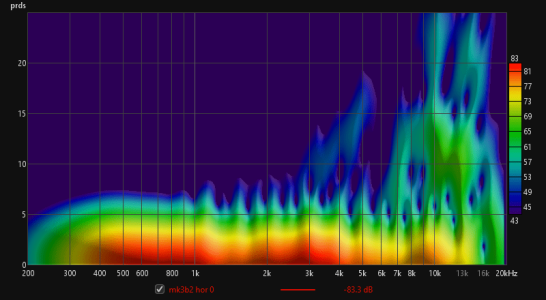

Energy decay

View attachment 78191

Impedance measurements of the driver without and with the horn

View attachment 78188

Here is the measurement set up for horizontal polars (Mic 2m away from horn)

View attachment 78185

Cleanness of impulse response for on-axis measurement

View attachment 78186

Raw measurements (0 degrees to 180 degrees off axis) gated at 6ms

View attachment 78187

Spinorma data with frequency response flattening equalization applied.

View attachment 78190

View attachment 78189

Energy decay

View attachment 78191

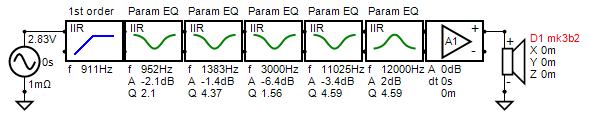

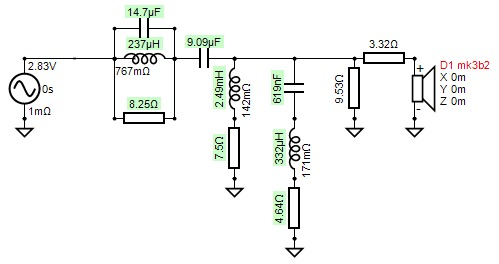

Applying a Linkwitz-Riley 4th order high pass filter showing a potential high pass that would be applied to the CD+horn in a 2 way system

Active version

View attachment 78192

View attachment 78193

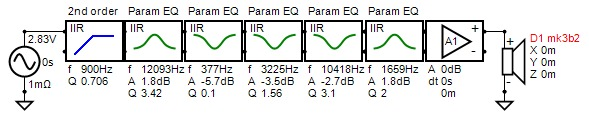

Passive version (not the optimized one and just made using transfer function replication based on active system crossover above)

View attachment 78194

View attachment 78195

Way forward from here

This is a really good constant directivity horn it seems.

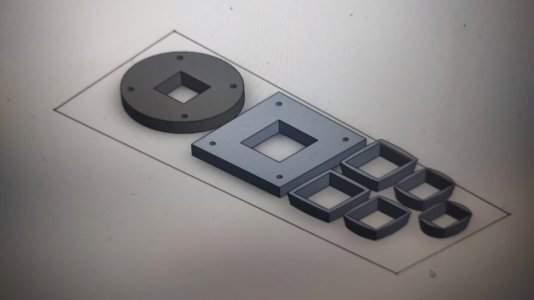

To get the last drop of performance (including high frequency extension beyond 14kHz) from it and to explore more possibilites, we are doing more testing. Testing with other drivers and other more optimized/sophisticated driver to horn adaptors to follow..