One other thing, what kind of a differnce can i expect when a driver is Kevlar and Paper.

This is an interesting question I have seen in HiFiVision after a long time. I was immediately tempted to do some research and here are my findings.

There is no such thing as the best material for cone. And a wide variety of materials are used. Do you know that Fostex makes some of the best drivers in the world, and some of their cones are made from banana pulp? Cone materials differ from each other in both mechanical and acoustical properties. Every material will involve some trade-off and compromises.

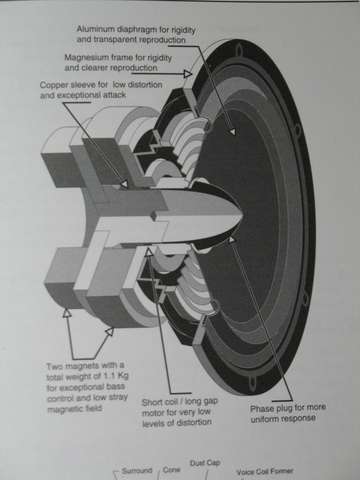

The three most important aspects of a material are its density, stiffness, and internal damping (also called lossiness). Designers use these materials to prevent a form of distortion called 'breakup'. This happens when the cone material starts flexing instead of moving as a perfect piston. Some of the better designed speakers have cones attached to sleeves on the outer edge that are stuck to the frame. This enables the cone to work more like a piston. Look at the speaker geometry below.

How important are the materials used for cones? Various materials are used and advertised as the 'best'. Different cone materials have different mechanical and acoustical properties that result in various performance compromises, making them better or worse suited for various situations. Essentially the cone should be lightweight. A lighter cone will respond faster to transient signals and have less mass that would make the cone continue to move after the signal has ceased. Designers therefore search for materials that combine stiffness with low mass.

One can argue that the best material for woofers cones is magnesium, and for tweeters, beryllium. These are also the most expensive. Beryllium has a different problem as espoused by Steve Mowry in his thread - http://www.hifivision.com/speakers/4679-whole-truth-about-beryllium-diaphragms.html

But, the material by itself does not result in a better sound. It is how well the designer uses the mechanical and acoustical properties that makes the difference. In any case let us look at some of the materials used for speaker cones.

Paper

Paper has been used for a long time as speaker cones. It's biggest advantage is that it can be formed into any shape quite easily. Untreated paper, unfortunately, is sensitive to environmental conditions. If there is humidity in the air, the moisture content in the paper changes. This leads to a change in the mass of the paper. Though paper can be made stiff, it is usually not stiff enough to get extended frequencies. In addition, paper is not lossy enough to deliver a smooth roll off. Lastly paper is not easy to manufacture with accurate consistency. These will always be miniscule differences between two rolls of paper, leading to differences in their properties.

The moisture issues is handled by applying various surface treatment that make the paper impervious to moisture. Treatments include latex and PVA based coatings.

In spite of these shortcomings, a well engineered paper can deliver bandwidth and smoothness as any other material.

Polypropylene

This is a common plastic material used in speaker cones. Polypropylene is never used by itself, but in combination with some material such as carbon fibre or Kevlar. By it's inherent mechanical property, Polypropylene is well damped thereby enabling it to deliver smooth and extended sound. Polypropylene has other advantages - it is immune to moisture and is easy to manufacture with consistent mechanical properties. Polypropylene is preferred by researchers who undertake analysis of drive units in advanced laboratories.

Polypropylene has two disadvantages - One, it is not easy to bond with other materials, but this has been solved to a large extent by modern adhesives. Second, and more important, is the degradation that invariably happens in the material characteristic. Over time, Polypropylene, like all plastics, will stretch under stress. In addition the heat generated by the voice coil could also soften the material over time.

Polypropylene, though, is a popular choice for high performance systems largely because of their well-behaved high-frequency response and consistent performance.

Other plastics materials used include TPX, HD-A, and HD-I, Neoflex, and Bextrene. All these represent attempts at finding combinations of stiffness, lossiness, density, and sound velocity that are optimal for a given application. They generally have the same virtues and potential pitfalls as polypropylene.

Woven fibres

Carbon fibre, fibreglass, or Kevlar fibres are bonded together with epoxy or similar resins. These fibres generally have high tensile strength, and become stiff when bonded together. These cones can deliver a large bandwidth and can be made comfortably in 8 inch or ever larger sizes to cover a large frequency range. But the high level of stiffness could introduce harshness in the sound signature, particularly in higher frequencies. Various manufacturers (such as B&W) employ various design features such as honeycombed structures to perfect the sound delivery of these fibres. All these pushes up the cost of the cones and thus the drive itself.

Woven fabrics, unlike, Polypropylene, will not lose their mechanical or acoustical properties over time. They are also impervious to moisture and heat, and are thus preferred for long life of the drivers.

Metal

Aluminium alloys and magnesium alloys are popular materials used for metal cones. Unfortunately, metals cones have the lowest internal damping and thus exhibit high peaks in high frequencies around 5KHz and above. Other than this singular breakup, metals behave well and are being increasingly used for cones.

Once you understand the basic characteristics of the materials used in a driver, you will find it easy to look out for specific sound signature. Ask the dealer for details on the materials used for the cones. For example, if an aluminium metal is used, look for sharp peaks in high frequencies. If it is a woven fabric, look for harshness in high frequencies. If it is paper look for how well the driver can cover a broad frequency range - play different music that cover both low and very high frequencies.

Best of luck in your audition.

Cheers